AUGUST 21, 2025

Can A Forklift Enter A 26 Ft Box Trucks

A forklift enter a 26 ft box truck when the truck meets certain standards. The box truck must have a strong floor and enough space for the forklift. Some box truck models do not allow a forklift to enter because of weak floors or low clearance. Operators must check if the box truck supports the weight of the forklift. Forklift enter is only safe when truck specifications match the needs of the forklift. Safety matters most during any forklift operation inside a box truck. Legal rules also affect if a forklift can enter the box truck.

Key Takeaways

A forklift can go inside a 26 ft box truck if the floor is strong, there is enough room, and the truck is tall enough. Operators need to check the truck’s floor, suspension, and lift gate. They must make sure these parts can hold the forklift and its load. Using the right dock tools and following safety rules helps stop accidents when loading or unloading. Forklift drivers need special training and a certificate to work safely with box trucks. They also must follow the law. Talking clearly and working together keeps everyone safe. It also helps forklift work inside box trucks go faster and smoother.

Forklift Enter: Feasibility

Box Truck Types

Not every box truck can handle a forklift enter. The type and class of the box truck matter most. Class 6 or larger box trucks usually work best for forklift entry. These trucks often have 22.5-inch wheels, which help them reach the right dock height. Most 26 ft box trucks in this class have an interior width and height of about 96 inches. This space allows a forklift to move inside and handle pallets safely.

Class 6 box trucks also have reinforced floors. These floors support the heavy weight of a forklift and its load. Single axle 26 ft box trucks and non-CDL trucks often have weaker floors. They may not support the combined weight of a forklift and a full pallet. Operators should always check the floor strength before a forklift enter. If the floor is weak, the risk of damage or injury increases.

Tip: Always inspect the box truck interior for damage or weak spots before loading with a forklift.

Dock Height Needs

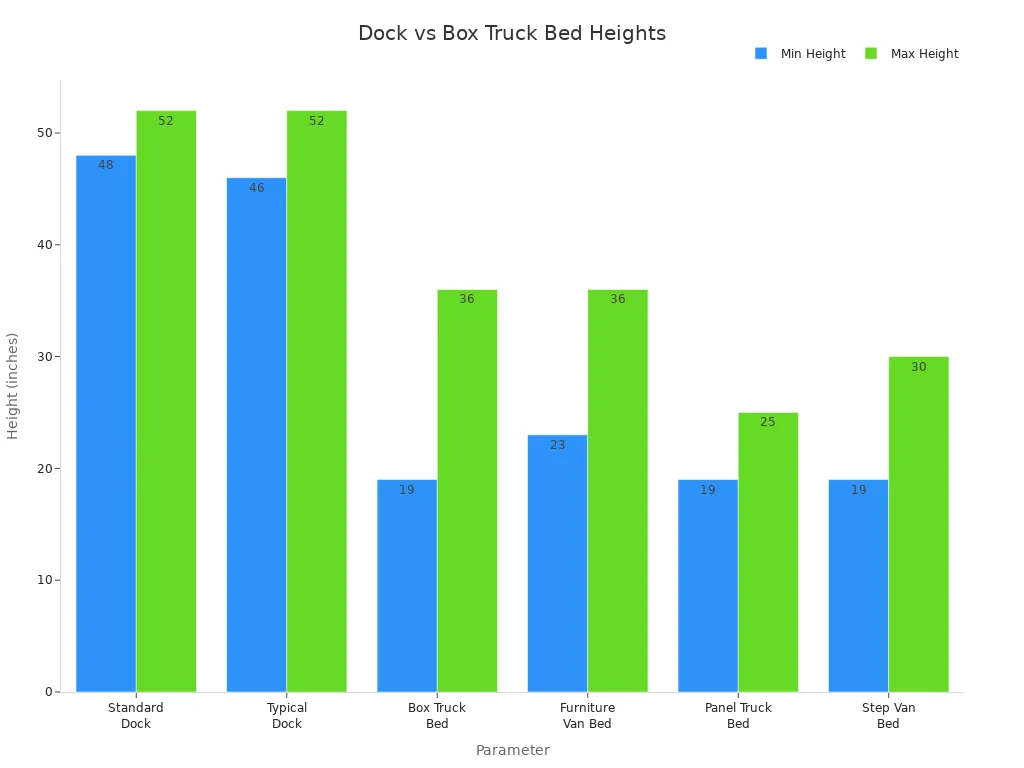

The dock height plays a big role in safe forklift enter. Most loading docks in the United States have a standard height between 48 and 52 inches. This matches the floor height of many Class 6 box trucks. When the dock and the height of the box truck match, a forklift can enter and unload pallets with less risk.

Some box trucks, like step vans or panel trucks, have lower bed heights. These can range from 19 to 36 inches. When the box truck sits lower than the dock, operators need special equipment. Dock levelers or elevating docks help bridge the gap. This keeps the forklift stable during loading and unloading.

| Parameter | Height Range (inches) |

|---|---|

| Standard Dock Height (most common) | 48 - 52 |

| Typical Dock Height Range | 46 - 52 |

| Box Truck Bed Heights | 19 - 36 |

| Furniture Van Bed Height | 23 - 36 |

| Panel Truck Bed Height | 19 - 25 |

| Step Van Bed Height | 19 - 30 |

Operators must also check the clearance inside the box truck. The forklift mast and load need at least 2 inches of space above them. If the height of the box truck is too low, the forklift may not fit. Always measure before starting to load or unload.

A safe forklift enter depends on several steps:

Park the box truck securely at the dock.

Set the brakes and check the wheels.

Inspect the floor for strength and damage.

Make sure the forklift and load fit inside the box truck.

Use the right dock equipment to match the height of the box truck.

Communicate with all team members during loading and unloading.

When all these factors line up, a forklift enter becomes safe and efficient. This helps move pallets quickly and keeps workers safe at the loading docks.

Requirements

Floor Strength

A forklift can go inside a box truck only if the floor is strong enough. The floor must hold the weight of the forklift, the load, and the pallets. Most 26 ft box trucks for heavy-duty jobs have floors that are reinforced. These floors stop bending or breaking when a forklift drives in. Operators should check the floor rating before loading anything. If the floor is weak, it might break and cause damage or hurt someone.

The gross vehicle weight rating, or GVWR, for most 26 ft box trucks is up to 26,000 lbs. This number includes the truck, the forklift, the load, and all pallets. Staying under this weight keeps things safe and legal. Going over the GVWR can mean fines or even accidents. Some box trucks have forklift loading packages. These packages have stronger floors and liftgates that can hold more weight. Operators should always add up the weight of the forklift, the load, and the pallets before starting.

Note: Always look for cracks, rust, or soft spots on the floor before driving a forklift into a box truck.

Suspension Type

The suspension system helps keep the box truck steady when a forklift enters. There are two main types: air ride suspension and spring suspension. Each type has good and bad points for forklift use.

| Aspect | Air Ride Suspension | Spring Suspension |

|---|---|---|

| Safety | Just as safe as spring suspension if checked and kept up. | Just as safe as air ride suspension if checked and kept up. |

| Ride Height Stability | Keeps the same height with different loads, which helps stability during forklift use. | Can get lower with heavy loads, which can make forklift entry less stable. |

| Vibration | Makes less vibration, so the ride is smoother and needs less fixing. | Makes more vibration than air ride suspension. |

| Dock Movement | Might move away from the dock during loading, but this can be stopped with dock locks or other devices. | Moves less at the dock but may have other limits. |

| Operational Advantage | Air system can change the floor height, making loading easier. | Cannot change the floor height. |

Air ride suspension keeps the box truck at the same height, even if the load changes. This helps the forklift get in and out safely. Spring suspension can get lower with heavy weight, making the floor uneven. This can make forklift work less steady. Air ride systems also make less vibration, which protects the forklift and the load. But air ride suspension can make the box truck move a little at the dock. Dock locks or wheel chocks can stop this movement.

Lift Gate Options

Lift gates help move a forklift and its load in or out of a box truck when there is no loading dock. The lift gate must be strong enough to hold the forklift and the load together. Most 26 ft box trucks have lift gates that can hold between 1,000 lbs and 3,000 lbs. This matches what most forklifts need to lift pallets in the box truck.

| Lift Gate Series | Typical Weight Capacity (lbs) |

|---|---|

| Railgate Series: High-Cycle GBR | 2,500 - 3,000 |

| Railgate Series: Standard | 1,600 - 2,000 |

| Railgate Series: Dock-Friendly | 1,600 - 2,000 |

| V2 Series: V2-45 | 1,100 |

| G2 Series | 1,000 - 2,000 |

Portable self-loading forklifts for box trucks can lift between 1,100 lbs and 3,300 lbs. These forklifts can load and unload pallets and then stay inside the box truck. There are electric and semi-electric models. Operators must always check the lift gate’s weight rating before using it. If you put too much weight on the lift gate, it can break and someone could get hurt.

Tip: Always make sure the lift gate can hold the total weight of the forklift and the load. Never go over the weight limit.

Staying under the box truck’s GVWR and the lift gate’s limit keeps forklift work safe. Operators should always add up the total weight before loading or unloading. This keeps the box truck steady and stops accidents.

Safety

Pre-Entry Checks

The team must do safety checks before a forklift enters a box truck. First, make sure the box truck is parked safely at the dock. The driver should set the brakes and put chocks on the wheels. Operators need to look for damage like cracks or weak spots on the floor. They also check if the dock plate is in the right place and can hold enough weight. The forklift needs a full check too, like brakes, lights, warning signals, and tires. These steps help stop tip-overs, falls, and other injuries that can happen when loading or unloading.

Tip: Always use a safety checklist before loading a box truck with a forklift.

Loading or Unloading Procedures

Planning is important for safe loading or unloading. Operators must know the weight limits for the forklift and the box truck. If needed, use a strong ramp that does not slip. The team should clear away anything in the way and plan the forklift’s path. When loading, balance the load from side to side and front to back. Wheel chocks and strong straps keep the forklift and pallets safe during the trip. Operators should drive slowly, especially if the ground is slippery or bumpy. On long trips, check the load and straps often. When unloading, follow the same forklift safety steps as when loading.

Common mistakes to avoid:

Not using wheel chocks or landing gear.

Driving too fast into or out of the box truck.

Using a dock plate that cannot hold the load.

Not noticing slippery floors or bad lighting.

Communication

Good communication keeps everyone safe when loading or unloading. Operators should talk to the box truck driver before starting. The team uses horns, warning lights, and hand signals to show what they will do. Spotters help in places where it is hard to see or when it is crowded. People walking nearby wear bright clothes so they can be seen. Operators use radios or hand signals to work together. Good communication helps stop accidents and makes the job go smoothly.

Note: A strong safety culture helps team members report dangers and rewards safe actions.

Training

Forklift Operator Certification

Forklift operators need special training before working with box trucks. Employers must teach operators how to use forklifts safely. The training has lessons, practice, and a test from a trainer. Operators learn about safe driving, controls, load limits, and moving cargo.

Employers must train and test operators for forklift safety.

Training uses talks, group work, videos, and handouts.

Operators practice and must pass a test.

Certification lasts three years. If someone drives unsafe, has an accident, or the workplace changes, they need more training.

OSHA does not ask for yearly training, but employers must keep records and run programs.

Operators must check forklifts before using them and drive in different places.

Records must show the operator’s name, training date, and trainer’s name.

Operators need more training if they drive unsafe, have an accident, or get a new forklift. If the workplace changes, training must be updated. Operators must be checked every three years to keep their certification.

Box Truck Regulations

Federal and state rules set standards for using forklifts with box trucks. These rules help keep workers safe. The table below shows important points:

| Regulation Aspect | Description |

|---|---|

| Scope | Federal rule 49 CFR § 176.78 covers forklifts used with box trucks. |

| Safety Features Required | Forklifts need warning lights, overhead guards, backrest extensions, safe forks, tire guards, and protected steering. |

| Designation and Certification | Forklifts must have labels like “E,” “EE,” “EX,” “G,” and “GS” for power and safety. |

| State Regulations | Virginia law covers forklift use, but other states may be different. |

| Authority to Suspend Use | The Captain of the Port can stop forklift use if it is unsafe. |

Warehouse workers and box truck drivers need training with lessons, practice, and safety updates. Training usually takes one day and teaches basics, load handling, and daily checks. Instructors, online classes, and virtual reality help workers learn safe habits. Pedestrian safety and trainer courses help keep everyone safe near box trucks. Picking the right forklift and keeping training current makes work safe and follows the rules.

A forklift can safely go into a 26 ft box truck if the floor is strong, the suspension works well, and the lift gate is used right. Operators need to check each box truck for weight limits and safety parts. Training and checking equipment often help stop accidents. Following the law keeps workers and property safe. If you want more help with box truck safety, groups like OSHA, Compliance Consultants, Inc., and KPA have good information:

OSHA shares rules for powered industrial trucks.

Compliance Consultants, Inc. gives forklift safety programs.

KPA offers training and advice for box truck work.

FAQ

Can every 26 ft box truck support a forklift inside?

No, not every 26 ft box truck has a strong enough floor or the right height. Operators must check the truck’s specifications before using a forklift inside.

What happens if the box truck floor is too weak?

A weak floor can bend or break under the forklift’s weight. This can damage the truck and cause injuries. Operators should inspect the floor for cracks or soft spots before loading.

Do operators need special training for forklift entry into box trucks?

Yes, operators need forklift certification and training on box truck safety. Employers must provide lessons and practice. Training helps prevent accidents and keeps workers safe.

Can a lift gate handle the weight of a forklift?

Most lift gates on 26 ft box trucks hold between 1,000 lbs and 3,000 lbs. Operators must check the lift gate’s rating before use. Exceeding the limit can cause the gate to fail.

English

English