AUGUST 26, 2025

Different Types of Forklifts

Many jobs use different types of forklifts. Forklifts help move, lift, and store items efficiently. Each forklift is designed for a specific task. The table below highlights the different types and what sets each type apart. Some forklifts carry heavier loads, while others perform better in particular environments.

| Forklift Type | Key Features | Common Uses |

|---|---|---|

| Warehouse Forklift | Twin forks, compact size | Moving pallets indoors |

| Side Loader | Sideways operation | Handling long items in tight areas |

| Counterbalance Forklift | Rear weight for balance | General warehouse tasks |

| Telehandler | Extendable arm, high reach | Lifting loads to high places |

| Heavy-Duty Forklift | Strong power, large capacity | Heavy industrial loads |

| Rough Terrain Forklift | Large tires, sturdy build | Outdoor, uneven surfaces |

| Pallet Jack | Small, manual or powered | Small loads in tight spaces |

| Reach Forklift | Extending forks, open compartment | Picking pallets from racks |

Choosing the right forklift from the different types available ensures worker safety and helps complete tasks more efficiently. It’s important to review the various types and their features, as well as consider the environment where the forklift will be used. This approach helps make the best selection.

Key Takeaways

Forklifts have many types. Each type is made for a special job or place. This helps make work safer and faster. Warehouse forklifts are used inside buildings. Electric ones are quiet and clean. They work well in small spaces. Heavy-duty and rough terrain forklifts carry very heavy things. They can drive on bumpy ground outside. They have strong engines and tough tires. Attachments like side shifters and rotators help forklifts do more jobs. These tools save time and fit different tasks. Picking the right forklift depends on how much weight you need to lift. It also depends on the ground, power type, space, and safety parts. Electric forklifts are good for inside because they do not make smoke or loud sounds. Internal combustion forklifts are better for hard work outside. Operators must get good training. Forklifts need regular checks to stay safe and work right. Narrow aisle and multi-directional forklifts save space. They help move long or big things in small places.

Different Types of Forklifts

Warehouse Forklifts

Features

Warehouse forklifts are very common in indoor spaces. They have small frames and comfortable cabins. Drivers can adjust their seats and armrests. The controls are easy to use. Some models lower noise and shaking. These forklifts have good visibility and safety tools. Overhead guards, backup alarms, and sensors help stop accidents.

Warehouse forklifts can use different power sources. Electric ones are quiet and do not make emissions. They are best for inside use. Diesel and LPG engines work in places with good airflow. Forklifts have different tires. Cushion tires are for smooth floors. Pneumatic tires work on rougher ground. How much a forklift can lift depends on height and load type. Data plates show safe limits for each setup.

Drivers can move loads from the cabin with side shifters and fork positioners. Cameras and sensors help keep the area safe. These forklifts also have stability controls and warning lights.

Tip: Pick a warehouse forklift based on the layout, load needs, and driver comfort.

Applications

Warehouse forklifts do many jobs. They move pallets and stack goods. They carry things across the warehouse floor. Drivers use them to load and unload trucks. These forklifts help put goods on racks and take them down. Warehouses use them every day for short moves and sorting products.

| Forklift Class | Key Features | Fuel Type | Typical Applications |

|---|---|---|---|

| Class I | Battery-powered, designed for indoor use | Battery | Warehouses, indoor pallet handling |

| Class II | Maneuvers in tight spaces, battery-powered | Battery | Moving inventory in narrow aisles |

| Class IV | Gas or diesel, cushion tires for smooth surfaces | Gas or Diesel | Indoor/outdoor smooth surfaces |

| Class V | Gas or diesel, pneumatic tires for rough terrain | Gas or Diesel | Indoor/outdoor with rough surfaces |

Warehouse forklifts help keep work safe and running smoothly.

Counterbalance Forklifts

Features

Counterbalance forklifts are the oldest and most well-known type. They have forks in front and a heavy weight in back. This keeps the forklift steady and stops it from tipping. Some have three wheels for better turning. Others have four wheels for more balance.

These forklifts can run on electric, diesel, gas, or LP gas. They can lift from 1 ton to over 25 tons. Drivers sit in comfy cabins with good views. Safety features include guards and seat belts. The forks can lift, tilt, and sometimes move sideways. These forklifts have safety systems and follow OSHA rules.

Applications

Counterbalance forklifts are used in many places. They unload trucks and load shipping containers. They store goods on high shelves. They move things in warehouses, printing shops, and shipping centers. They are also used on TV and movie sets to move heavy gear.

Counterbalance forklifts are more stable and flexible than reach forklifts or order pickers. They work well both inside and outside. This makes them good for many jobs.

Side Loader Forklifts

Features

Side loader forklifts are special because they move long and big items. Their forks are on the side, so they pick up loads from the side. They work well in narrow aisles and tight spots. This saves space and lets you store more. Their small size and tight turning help in low rack areas.

Some models can steer in many directions and carry heavy loads. Drivers can see well and move easily. Side loader forklifts come in electric and gas versions. They can be used inside or outside.

Note: Side loader forklifts protect long items and storage racks by not lifting overhead.

Applications

Lumber, building, and factories use side loader forklifts for long, heavy things. Drivers use them to move wood, metal pipes, and big parts. These forklifts are great for moving lots of stuff fast and safely. Their side-loading makes them perfect for loading trucks in small spaces.

Side loader forklifts also work with special racks like cantilever racks. They help save space and make warehouse work better.

Telehandlers

Features

Telehandlers are also called telescopic handlers. They can lift things like a forklift and reach far like a crane. These machines have a long boom that stretches out and up. Some booms stay in one place, but others can turn. You can put different tools on the end, like forks or buckets. This makes telehandlers useful for many jobs.

Most telehandlers have four-wheel drive and big tires. These help them move on bumpy or rough ground. The cabins are made to be safe and comfy. Drivers can see well and use simple controls. Some new models have cameras and sensors for better views. Safety systems stop tipping and keep loads steady up high.

Tip: Telehandlers can reach places other forklifts cannot. This makes them helpful for many kinds of work.

Applications

Telehandlers are used a lot in building and farming. Workers use them for many things:

On building sites, telehandlers lift heavy stuff to high places. They help with building, moving things, and putting items in the right spot.

Fixed boom telehandlers are steady and work well with forks and buckets.

Rotating boom telehandlers let you move things at different angles or over stuff.

On farms, telehandlers move feed, seeds, and crops. They load grain, stack hay, and carry big loads.

Farmers use them for planting trees, leveling land, and putting up fences.

Other jobs include clearing snow, fixing farm buildings, and helping with animals.

Switching tools is fast, so telehandlers are one of the most used forklifts for jobs needing both reach and strength.

Heavy-Duty Forklifts

Features

Heavy-duty forklifts are made for very hard jobs. They can lift very heavy things, from 44,000 to 115,000 pounds. Some can lift even more. These forklifts have strong frames and big engines like Volvo or Cummins. They use special transmissions like Dana or ZF for smooth driving.

Drivers sit in cabins made for comfort during long work. Many cabins have air control and clear windows for good views. Heavy-duty forklifts save fuel with Eco-Drive and special hydraulics. Some can use HVO100 fuel, which cuts CO2 by up to 90%.

| Specification | Details |

|---|---|

| Lifting Capacity (lbs) | 44,000 to 115,000 |

| Load Center (inches) | 48 |

| Engine Options | Volvo, Cummins |

| Transmission Options | Dana, ZF |

| Operator Cabin | Ergonomic EGO cabin |

| Fuel Efficiency | Eco-Drive, variable hydraulics |

| Environmental Benefits | Up to 90% less CO2 with HVO100 fuel |

| Typical Environments | Metal, concrete, heavy industry, logistics, rail cargo, shipping yards |

Heavy-duty forklifts have safety tools like load sensors and strong brakes. Drivers must check the data plate for safe weight limits. Lifting too much can cause accidents.

Applications

Heavy-duty forklifts are used where big, heavy things need moving. These trucks are found in:

Metal and steel factories

Concrete plants

Heavy industry and making things

Shipping yards and ports

Rail cargo work

Big warehouses and logistics centers

Some types, like high-capacity cushion forklifts, are used in car making and steel work. Others, like marina forklifts, move boats and heavy gear at docks. Heavy-duty forklifts are needed for jobs that need power, safety, and trust.

Rough Terrain Forklifts

Features

Rough terrain forklifts are made for outside on bumpy or slippery ground. They have big tires with deep treads for better grip. Four-wheel drive and high clearance help them go over rocks, mud, or gravel. The frame is extra strong, and the wide base keeps them steady.

Safety is very important. Rough terrain forklifts have rollover bars to stop tipping. They also have shields to protect drivers from falling things. Seatbelts and restraints keep drivers safe. Backup alarms and cameras help drivers see and warn others. Load sensors and controls stop tip-overs and keep the forklift balanced.

Note: People need special training to use rough terrain forklifts. Outdoor ground can change fast.

Applications

Rough terrain forklifts are used in:

Building sites with rough ground

Lumber yards and sawmills

Farms and fields

Outdoor event setups

Mining and quarry work

Drivers use these trucks to move building stuff, logs, pallets, and gear on rough ground. The strong tires and safety tools make rough terrain forklifts the best choice for outside jobs where other forklifts might not work.

Pallet Jacks

Features

Pallet jacks are the easiest forklifts to use. There are two main types: hand pallet trucks and powered pallet trucks. Hand pallet trucks use a pump handle to lift and move pallets. Powered pallet trucks use an electric motor to help move and lift things. Both types are small and fit in tight spaces.

Hand pallet trucks turn easily in small areas. People can move them without much effort. The forks slide under regular pallets. Most pallet jacks can lift between 4,500 and 5,500 pounds. Powered pallet trucks have extra features like speed controls and safety alerts. Some have special systems to keep people safe.

Tip: You do not need special training for pallet jacks, but always follow safety rules.

Applications

Pallet jacks are important in many jobs. They help move things quickly and safely. People use them for:

Moving goods on pallets for restocking and shipping in warehouses.

Unloading trucks and sorting items in stores.

Loading and unloading vehicles in shipping and delivery.

Carrying heavy things on building sites where big forklifts cannot go.

Helping factories move raw materials and finished products.

Handling frozen and fresh foods in cold storage and food places.

Hand pallet trucks are good for short trips and lighter loads. Powered pallet trucks work better for heavier loads and longer trips. Both types help save time and make work easier. Many companies use pallet jacks as backup when forklifts are busy. They are quiet and do not make fumes, so they are great for cold storage and stores.

Walkie Stackers

Features

Walkie stackers are special forklifts for small spaces. People walk behind or next to them and guide them with a handle. They use electric power, so they are quiet and clean. Walkie stackers are smaller than most forklifts. This helps them move in narrow aisles and crowded places.

Some walkie stackers have arms that go around the pallet for better balance. This helps them turn in tight spots. Walkie reach stackers can stretch their forks forward to place loads. Ride-on walkie stackers let people stand on a platform to move faster in bigger areas.

Walkie stackers lift lighter loads, from a few hundred to a few thousand pounds. They can stack things on racks up to 20 feet high. Their low center of gravity keeps them from tipping over. These machines are easy to control and work well in small spaces.

Applications

Walkie stackers are best for indoor places with little room. They are used in store warehouses, distribution centers, and small factories. People use them to:

Stack pallets on racks that are not too high.

Move things in narrow aisles.

Load and unload trucks in small areas.

Organize items in backrooms and storage spaces.

Walkie stackers help save space and make work safer. Their electric power and simple controls are good for moving lighter loads in small places.

Order Pickers

Features

Order pickers are forklifts made for picking single items from racks. The person stands on a platform that goes up with the forks. This lets them reach things stored at different heights. Order pickers use electric power, so they are quiet and clean.

These machines often work with warehouse computer systems. Some use paperless systems, voice commands, or lights to help pick items. These features help workers make fewer mistakes and work faster. Order pickers have easy-to-use controls and platforms that adjust. This helps workers feel less tired and work longer.

Order pickers can reach up to 20 feet high or more. They are made for picking items, not for moving heavy pallets. Their design helps workers pick things quickly and safely.

Applications

Order pickers are very important in online shopping and store warehouses. Their main job is to get items from shelves to fill orders. Workers use different ways to pick items, like batch picking, zone picking, and pick-and-pass, to save time and work better.

Order pickers help companies:

Pick items quickly and correctly.

Make fewer mistakes when filling orders.

Deliver orders faster and keep customers happy.

Organize items for easy picking.

Use new technology to work better.

Order pickers are needed in modern warehouses. They help businesses ship orders fast and get them right.

Types of Forklift Trucks by Power

Picking the right power for a forklift is important. There are two main types: electric forklifts and internal combustion forklifts. Each type has good points and some problems. Knowing these differences helps companies choose the best forklift for their needs.

Electric Forklifts

Benefits

Electric forklifts run on batteries. They do not make exhaust, so they are safe inside. These forklifts are quiet and help keep warehouses calm. Many companies like them because they save energy and cost less to run. Electricity is cheaper than gas, diesel, or propane. Electric forklifts also have fewer parts, so they break less often.

Electric forklifts help companies follow air and safety rules. Their small size and sharp turns help in tight spaces.

Some main benefits of electric forklifts are:

No emissions, so they are good for food and storage places.

Lower fuel and repair costs.

Quiet, which makes work nicer.

New batteries make them use less energy.

They work for both stand-up and sit-down forklifts.

Limitations

Electric forklifts have some problems in busy places. Their batteries need to be charged often, which takes hours. Lead-acid batteries are best for one shift because they need long breaks to charge and cool. Lithium-ion batteries charge faster and can work longer, but they cost more. Batteries wear out and must be replaced, which adds to costs.

Most electric forklifts do not work well outside or in wet places unless protected. Water can hurt their electric parts. They also cost more at first because of batteries and chargers. They may not work well on steep hills or in very small spots.

| Operational Limitation | Explanation |

|---|---|

| Limited Run Time | Batteries need charging, which can stop work. |

| Higher Upfront Costs | They cost more at first because of batteries and chargers. |

| Battery Wear and Replacement | Batteries wear out and need to be replaced after a few years. |

| Limited Outdoor Suitability | Most do not work outside or in wet places. |

| Application Constraints | Not good for steep hills or very tight spaces. |

Internal Combustion Forklifts

Benefits

Internal combustion forklifts use diesel, gas, or propane. They have strong engines and can lift heavy things. They work well outside, even on rough ground or in bad weather. These forklifts can run for a long time without stopping to charge. Drivers can refuel fast by changing tanks, so there is less waiting.

Some good things about internal combustion forklifts are:

They can lift heavy and big things.

They are tough and work on bumpy ground.

They work well in hot, cold, or wet weather.

They cost less at first than electric forklifts.

They can use different fuels and tools.

These forklifts are used in building, farming, and mining. Their big tires and high base help them move over rocks, mud, and gravel.

Limitations

Internal combustion forklifts make exhaust, which is bad for air inside. Companies need good airflow when using them indoors. They are also louder than electric forklifts. They cost more to fix because they have more parts. Fuel costs more than electricity.

These forklifts pollute the air with gases and chemicals. Using cleaner fuels like propane and running them less can help. But they still need oil and fluid changes, which makes more waste.

| Aspect | Electric Forklifts | Internal Combustion Forklifts |

|---|---|---|

| Energy Source | Batteries turn electricity into power | Diesel, gas, or propane turn fuel into power |

| Energy Efficiency | Use energy well | Lose more energy as heat |

| Emissions | No exhaust | Make exhaust that hurts air |

| Noise Level | Very quiet | Louder |

| Typical Use | Best for inside because no fumes | Best for outside because of exhaust |

Tip: Electric forklifts are best inside. Internal combustion forklifts are better outside and for heavy jobs.

Forklift Classifications

OSHA Classes I-VII

Overview

The Occupational Safety and Health Administration, or OSHA, has a way to group forklifts. This helps companies pick the right forklift and train workers to use them safely. OSHA puts forklifts into seven classes. These classes are based on how they are powered, how they are built, and where they work best. Each class has its own safety rules and training. Workers must get special training for the class they use. This helps stop accidents and keeps everyone safe at work.

Here is a table that shows the main OSHA forklift classes and what they are used for:

| OSHA Forklift Class | Power Source / Design Description | Typical Use / Notes |

|---|---|---|

| Class I | Electric motor rider trucks | Common indoor use, battery powered |

| Class II | Electric motor narrow aisle trucks | Designed for narrow aisles, indoor warehouse use |

| Class III | Electric motor hand trucks or hand/rider trucks | Hand-operated or hand/rider trucks, smaller scale operations |

| Class IV | Internal combustion engine trucks (solid/cushion tires) | Used indoors or on smooth surfaces, cushion tires |

| Class V | Internal combustion engine trucks (pneumatic tires) | Outdoor or rougher surfaces, pneumatic tires |

| Class VI | Electric and internal combustion engine tractors | Tractors used for towing or pulling |

| Class VII | Rough terrain forklift trucks | Designed for outdoor, uneven terrain, construction sites |

OSHA’s system is important for training and certification. It makes sure workers know how to use each forklift safely.

Key Differences

Each OSHA class is different. These differences change where and how the forklift works best. The table below shows the main ways they are not the same:

| OSHA Forklift Class | Engine Type | Tire Type | Design/Key Features | Typical Applications |

|---|---|---|---|---|

| Class I | Electric | N/A | Counterbalanced sit/stand rider, 3 or 4 wheels | Indoor use, zero emissions, general material handling |

| Class II | Electric | Solid | Narrow aisle trucks, order pickers, side loaders | Tight/narrow indoor spaces, high lift heights |

| Class III | Electric | N/A | Hand-controlled pallet jacks, walkie stackers | Short distance pallet transport indoors |

| Class IV | Internal Combustion (gas, diesel, LPG) | Cushion tires | Counterbalanced, designed for smooth indoor floors | Heavy loads on flat indoor surfaces |

| Class V | Internal Combustion (gas, diesel, LPG) | Pneumatic tires | Counterbalanced, suitable for rough terrain | Outdoor and indoor rough or uneven surfaces |

| Class VI | Electric or Internal Combustion | N/A | Tow tractors, sit/stand, no lifting function | Towing materials in airports, assembly lines |

| Class VII | Internal Combustion (gas, diesel) | Tractor-style pneumatic | Rough terrain forklifts with suspension, all/four-wheel drive | Uneven, hilly, or wet outdoor terrain |

Companies use these classes to pick the best forklift for each job. For example, electric forklifts are good inside because they do not make smoke. Forklifts with pneumatic tires are better for rough ground outside. Narrow aisle trucks fit in small warehouse spaces. This system helps keep workers safe and helps companies choose the right forklift.

F1 and F2 Categories

Man Up vs. Man Down

Some places use another way to group forklifts by how much they can lift. F1 stacking trucks can carry up to 3,000 kg. F2 stacking trucks can carry up to 7,000 kg. These groups help companies pick the right truck for the weight they need to move.

There are also two main types of stacking trucks. These are called man up and man down. The table below shows how they are different:

| Aspect | Man-Up Forklift | Man-Down Forklift |

|---|---|---|

| Operator Position | Operator rises with the forks, working at height | Operator remains on the ground |

| Safety | Requires more safety protocols due to elevated position | Safer environment as operator stays on ground |

| Efficiency | Slower, focused on accurate picking at various rack levels | Faster, optimized for high-volume pallet handling |

| Operator Skill | Needs trained operators comfortable with heights | Easier for standard forklift operators |

| Main Use | Order picking at multiple rack levels | Full pallet handling |

| Warehouse Suitability | Suitable for high-rack, multi-SKU environments | Best for standard pallet in/out in tall racks |

| Cost | Higher purchase and maintenance cost | More cost-effective |

| Best Applications | E-commerce, pharmaceuticals, piece-picking warehouses | Distribution centers, cold storage, automated warehouses |

| Flexibility | Good for varied items and frequent access | Best for uniform pallet loads |

| When to Choose | Frequent picking at height | High-volume pallet transport |

Man up trucks lift the worker with the load. This helps them pick things from high shelves. Man down trucks keep the worker on the ground. They are faster for moving full pallets. Companies choose which type to use based on their warehouse and safety needs.

Specialized Forklift Types

Narrow Aisle Forklifts

Narrow aisle forklift truck equipment helps companies use space better. These trucks fit where regular forklifts cannot go. Many warehouses use electric motor narrow aisle forklifts for tall racks. Operators can pick from different types, and each has special features.

| Forklift Type | Specialized Features | Advantages |

|---|---|---|

| Reach Trucks | Extendable forks, open mast design for visibility, designed for high-density vertical storage. | Efficient vertical space use, precise load handling, ideal for tall shelving in narrow aisles. |

| Order Pickers | Operator platform lifts with forks, designed for picking individual items rather than pallets. | Faster picking, better accuracy, great for e-commerce and retail in narrow aisles. |

| Turret Trucks (VNA) | Rotating forks allow load handling without turning the truck, operate in aisles less than 6 feet wide. | Maximize storage, high throughput, perfect for high-density warehouses. |

| Articulated Forklifts | Chassis with pivot joint lets front pivot independently, suitable for narrow and standard aisles. | Flexible use, improved maneuverability, reduces need for multiple forklift types. |

Electric motor narrow aisle trucks help store more in less space. These forklift truck equipment types make warehouses safer and faster.

Tip: Narrow aisle forklifts let racks stand closer together to store more.

Multi-Directional Forklifts

Multi-directional forklifts carry long and big loads in small spaces. These trucks can move forward, backward, sideways, and diagonally. Operators turn and move through narrow aisles easily. This saves both time and space.

Multi-directional forklift truck equipment moves any way, so it is easy to carry pipes, lumber, or steel beams.

Operators see better because the forks are on the side and the view is open.

The small design fits into tight aisles, so you can store more.

Adjustable forks and strong frames help lift heavy or odd-shaped loads.

These trucks work well on bumpy or wet ground, so they always perform well.

Safety features like stability control and careful stacking help stop accidents.

Battery-powered models make less pollution and cost less to fix.

Companies can change these forklifts for special jobs.

Multi-directional forklifts help many places, like lumber yards and factories. Operators move big things safely and fast, even in busy areas.

Attachments

Attachments make forklift truck equipment do more jobs. Operators add tools to handle different loads and tasks. Some common attachments are:

Side Shifter: Moves loads left or right for better placement. This saves time and stops damage.

Fork Positioner: Changes fork width with hydraulics, so it is easier to pick up different pallets.

Paper Clamps: Hold paper rolls safely, which helps in printing and packaging.

Push/Pull Attachment: Handles slip-sheeted loads without pallets, so packaging weighs less.

Multiple Pallet Handler: Lifts more than one pallet at once, so loading is faster.

Fork Extensions: Makes forks longer for big or odd-shaped loads.

Rotators: Spins loads all the way around, which helps dump or flip things.

Operators can also use clamps for boxes, drums, or bales, and special tools like carpet poles or jib booms. These attachments help forklift truck equipment do more with one machine. Companies save money and time by picking the right tool for each job.

Note: Attachments make forklifts safer and faster by matching the tool to the job.

Choosing a Forklift

Load Capacity

To pick the right forklift, first know how much it needs to lift. Each forklift has a top weight it can carry. Operators should look at the usual and heaviest loads they have. The load center is the space from the load’s middle to the forklift’s backrest. This changes how much weight the forklift can lift safely. Most forklifts use a 24-inch load center. If the load is long or heavy on one side, the safe weight goes down.

Attachments like side shifters or clamps can make the forklift carry less. Operators also need to think about how high they must lift. Forklifts lose lifting power as the mast goes up. The kind of forklift matters too. Three-wheel forklifts turn better but carry less. Four-wheel forklifts are steadier and can lift more. Tire type is important. Pneumatic tires are good for rough ground. Cushion tires work best on smooth floors.

| Factor | Considerations and Recommendations |

|---|---|

| Carrying Capacity | Check average and maximum load weights; consider load size and fork length. |

| Load Center | Standard is 24 inches; longer loads reduce safe capacity. |

| Attachments | Reduce effective load capacity. |

| Mast Height | Higher lifts lower capacity. |

| Number of Wheels | 3-wheel: better turning, less capacity; 4-wheel: more stability, higher capacity. |

| Tire Type | Pneumatic for rough terrain; cushion for smooth floors. |

| Work Environment | Indoor vs outdoor, height limits, load access. |

Tip: Always look at the forklift’s data plate to see safe weight limits before lifting.

Terrain

The ground where you use a forklift changes which one is best. Warehouses with smooth floors need forklifts with cushion tires. These tires give a smooth ride and help carry heavy things. Electric forklifts are used inside because they are quiet and do not make fumes.

Outside areas with bumpy ground need rough terrain forklifts. These forklifts have big, tough tires and sit high off the ground. They use ic engines like diesel or gas for more power. Construction sites, lumber yards, and farms use these forklifts a lot. Slopes or tight spots need forklifts with strong brakes and engines. Operators should choose a forklift that fits the ground and keeps everyone safe.

| Terrain Type | Recommended Forklift Model | Tire Type | Fuel Type / Power Source | Key Considerations |

|---|---|---|---|---|

| Indoor (Smooth Floors) | Electric Forklifts | Cushion Tires | Electric | Clean, quiet, safe for warehouses |

| Outdoor (Rough Terrain) | Rough Terrain Forklifts (RTFL) | Rugged, high-clearance | Diesel or Gas (ic) | Handles gravel, dirt, prevents stalling |

| Slopes/Tight Spaces | Powerful engine forklifts | N/A | N/A | Needs strong brakes, good maneuverability |

Note: The right tires and engine help forklifts work safely on any ground.

Power Source

The power source changes where and how a forklift can be used. Electric forklifts use batteries and are best for inside jobs. They do not make fumes and are very quiet. These forklifts are good for places with lots of stuff and small aisles. Some use special batteries that last longer and work in hot or cold places.

Ic forklifts use diesel, gas, or LPG. Diesel forklifts are strong and work well outside or for heavy jobs. Gas and LPG forklifts can be used inside or outside, but they do make some fumes. Ic forklifts can refuel fast, so they are good for long days or busy places. Picking the right power source depends on what the company needs, the rules, and where the forklift will be used.

Electric forklifts: Best for inside, no fumes, very quiet.

Diesel ic forklifts: Best for outside, heavy work.

LPG ic forklifts: Can be used inside or outside, but make some fumes.

Tip: Pick the power source that fits the job site and work hours for the best results.

Space

Space is very important when picking a forklift. Every warehouse or job site looks different. Some places have wide aisles and tall ceilings. Other places have small paths and short racks. The forklift must fit and move easily in these areas. Forklifts come in many sizes. Small forklifts turn well in tight spots. Big forklifts need more space to move and turn. Operators should measure the aisle width before choosing a forklift. Many warehouses use narrow aisle forklifts to save room. These forklifts work in aisles as small as six feet. Standard forklifts need wider aisles, usually more than twelve feet. Storage height matters too. Some forklifts lift loads very high. Others only reach lower shelves. Operators should check how high they need to lift. Picking a forklift with the right mast height helps use all the storage space.

| Space Type | Recommended Forklift | Key Features |

|---|---|---|

| Narrow Aisles | Reach Truck, Order Picker | Tight turning, high lift |

| Standard Aisles | Counterbalance Forklift | Stable, easy to operate |

| Low Ceilings | Low Mast Forklift | Compact, fits under obstacles |

| High Storage Racks | High-Reach Forklift | Tall mast, stable at height |

Tip: Operators should always check the warehouse layout and measure aisles before picking a forklift. This helps stop accidents and keeps work moving well.

Safety

Safety is the most important thing when picking a forklift. Every worksite has risks, but some places need extra care. Forklifts now have many safety features to help keep people safe.

Some important safety features are:

Operator Protection Systems: These use seat belts, restraints, overhead guards, and load backrests. They help protect operators from rollovers and falling things.

Advanced Safety Technologies: Overload sensors and stability controls help stop tip-overs and overloading. SMART dash screens give warnings and show if the forklift needs fixing.

Visibility and Awareness Enhancements: Good lights, mirrors, cameras, and alarms help operators see better and warn others. Blue spotlights and warning signs make forklifts easier to notice.

Proximity and Collision Avoidance Technologies: Proximity sensors, pedestrian detectors, and collision warnings lower accident risks. Some forklifts have automatic brakes and safety zone systems.

Load Handling and Stability Aids: Tilt, lift, and load indicators, plus load weight sensors, help operators handle loads safely. Special attachments can also help balance and control.

Operator training and certification are very important. Trained operators know how to use safety features and follow safe driving rules. Companies should make sure every operator gets good training and keeps learning.

Note: Picking a forklift with strong safety features and making sure operators have the right training can stop injuries and keep everyone safe at work.

Forklift Safety

Training

Good forklift training keeps workers safe and stops accidents. OSHA says all forklift drivers must finish training before using a forklift. Training has classroom lessons, hands-on practice, and tests. Each forklift type needs its own training because they work differently. Companies must keep training records and give new training every three years or after an accident.

| Forklift Type | Key Training Components | OSHA Requirements | Additional Best Practices |

|---|---|---|---|

| Electric Forklifts | Formal instruction, practical experience, inspection, maintenance, safe operation, workplace hazards | Certification before operation, refresher training every 3 years or after incidents, record keeping | Tailored training to specific hazards, ongoing updates to training programs |

| Electric Pallet Jacks | OSHA requirements, safe operation, maintenance, certification | Maintain accurate training records, regular program reviews to avoid fines | Emphasis on compliance to prevent penalties |

| Reach Trucks | Specific workplace hazard training, safe operation | Adherence to OSHA regulations, refresher training every 3 years or post-incident, detailed records | Focus on workplace-specific hazards |

| Internal Combustion (Cushion Tires) | Inspection, maintenance, safe operation | Detailed certification records, OSHA compliance | Regular training program reviews prioritizing safe operation |

| Heavy Duty Forklifts | Comprehensive training, safe operation, maintenance, formal instruction, hands-on training, performance eval | Refresher training every 3 years, certification, compliance with OSHA standards | Training tailored to industry use cases (manufacturing, freight, warehousing) |

Tip: Companies should update training often to match new dangers at work.

Maintenance

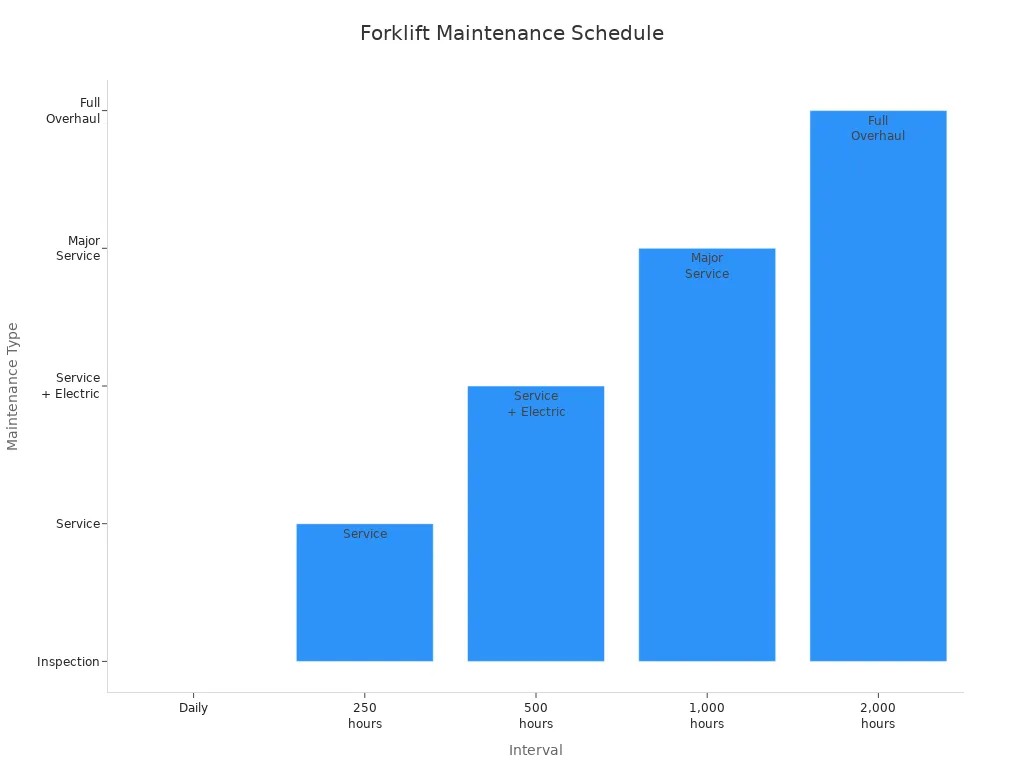

Regular maintenance keeps forklifts safe and working right. Drivers should check forklifts every day before using them. They look for leaks, tire damage, and test brakes and lights. If something is wrong, it must be fixed right away. Forklifts need bigger checks after a certain number of hours. These checks include changing fluids, looking at chains, and testing the engine.

Daily checks look at brakes, steering, hydraulics, tires, alarms, and mirrors.

Drivers must fix or replace broken parts right away.

Fluid levels like brake, hydraulic, and engine oil need checking often.

Electric forklifts need motor checks, cable checks, oiling, and battery care.

Planned maintenance lowers accident risk, saves money, and helps forklifts last longer.

Note: How often you do maintenance depends on how much the forklift is used and where it works.

Operation Tips

Safe forklift driving keeps people and equipment safe. Drivers should always follow safety rules and pay attention.

Always wear a seatbelt and use safety gear.

Check the forklift before every shift.

Drive slowly and watch for people.

Keep loads low and balanced.

Never let people ride on the forks.

Use horns and lights to warn others.

Do not make sharp turns or stop suddenly.

Park on flat ground and lower the forks when done.

Drivers who follow these tips help make the workplace safer for everyone.

Learning about the types of forklifts helps workers stay safe. Each forklift works best for certain jobs or places. Choosing the right forklift makes work safer and faster. Companies should think about what they need before getting equipment.

If you need more help, ask a forklift expert or look at trusted guides. Every job site is different. Getting advice made for your workplace can help you pick the best forklift.

FAQ

What is the most common type of forklift used in warehouses?

Warehouse forklifts are used the most. They move pallets and goods inside buildings. Many companies pick electric models because they are quiet and do not make fumes.

How often should operators inspect a forklift?

Operators need to check forklifts before each shift. Daily checks help find problems early. This keeps the forklift safe and working well.

Can forklifts be used outdoors?

Yes, some forklifts work outside. Rough terrain forklifts and internal combustion models handle bumpy ground and bad weather. Electric forklifts are mostly used indoors.

What is the difference between a pallet jack and a forklift?

A pallet jack moves small loads for short trips. It cannot lift things very high. A forklift lifts heavier items and stacks them on shelves.

Do all forklift operators need special training?

Yes. OSHA says all forklift operators must finish training and get certified. This rule helps stop accidents and injuries.

How do attachments improve forklift use?

Attachments help forklifts do more jobs. For example, a side shifter moves loads left or right. A rotator spins items for dumping. These tools make forklifts more useful.

What should companies consider when choosing a forklift?

Companies should think about load weight, work area, power source, and safety features. Picking the right forklift makes work safer and faster.

Tip: Always look at the forklift’s data plate to see safe lifting limits.

English

English