AUGUST 26, 2025

Forklift Industry Trends and Regulations in 2025

The forklift industry in 2025 changes fast. This is because of new rules and better technology. Companies like electric forklifts more now. These forklifts do not make pollution and need less fixing. They also follow EPA and OSHA rules. IoT and telematics help watch forklifts in real time. Better batteries help too. These things help companies stop delays and keep workers safe. Using these trends early helps companies work well and follow rules. This also helps them grow in a market worth $81.44 billion.

Key Takeaways

The forklift market is growing quickly all over the world. E-commerce, construction, and new technology help this growth. Electric forklifts use lithium-ion batteries. These batteries last longer and charge faster. They also help companies follow environmental rules. Automation and AI make forklifts safer and more efficient. Smart navigation and operator assist systems help with this. Telematics and predictive maintenance track forklift health in real time. This helps reduce downtime and shows how forklifts are used. VR and AR training give safe and effective ways to teach operators. This training also makes the workplace safer. New safety rules say operators must get proper training. Forklifts need regular checks and updated safety features. Companies must follow emissions rules. They do this by using electric forklifts and reporting fleet data. Using new technology and training workers helps companies stay safe. It also helps them follow rules and compete with others.

Forklift Industry Overview

Market Growth

Global Expansion

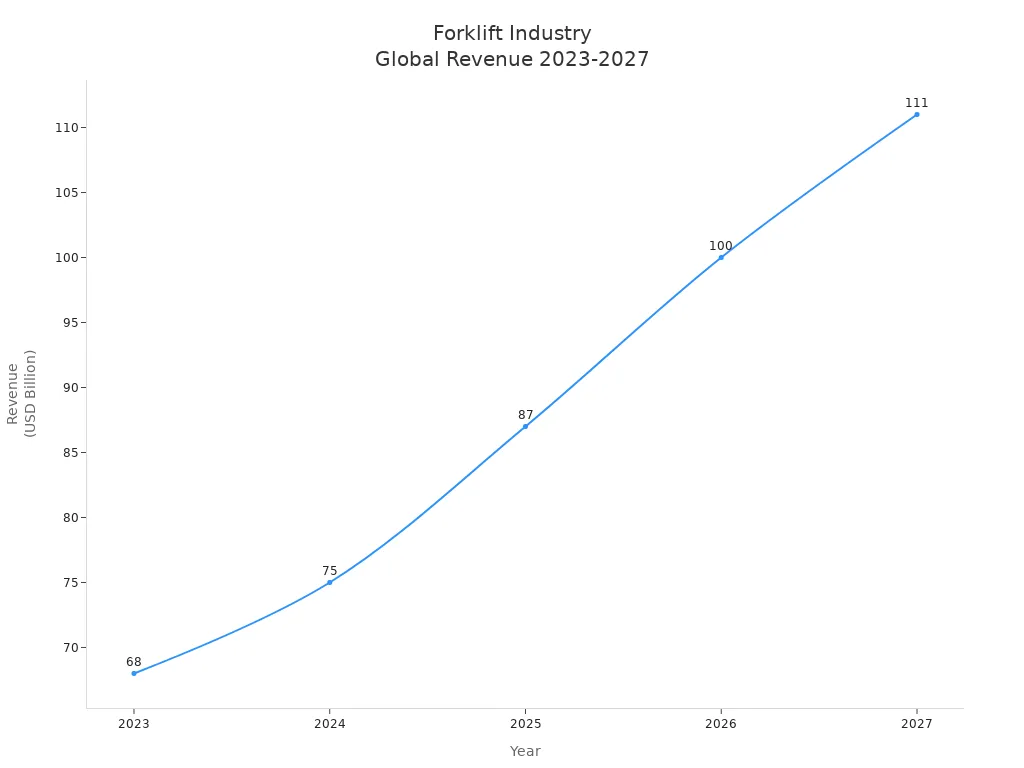

The forklift industry is growing in many countries. In 2024, the market was worth $81.8 billion. Experts think it will keep growing every year. The growth rate is about 5.6% from 2025 to 2034. By 2034, the market could be $137.9 billion. This shows forklifts are very important for moving goods and helping supply chains.

| Attribute | Value |

|---|---|

| Base Year | 2024 |

| Global Market Size 2024 | USD 81.8 billion |

| CAGR (2025-2034) | 5.6% |

| Projected Market Size 2034 | USD 137.9 billion |

More people want forklifts for jobs in warehouses and factories. Companies buy new forklifts to work faster and follow rules. The market is also growing because of electric and self-driving forklifts.

Regional Trends

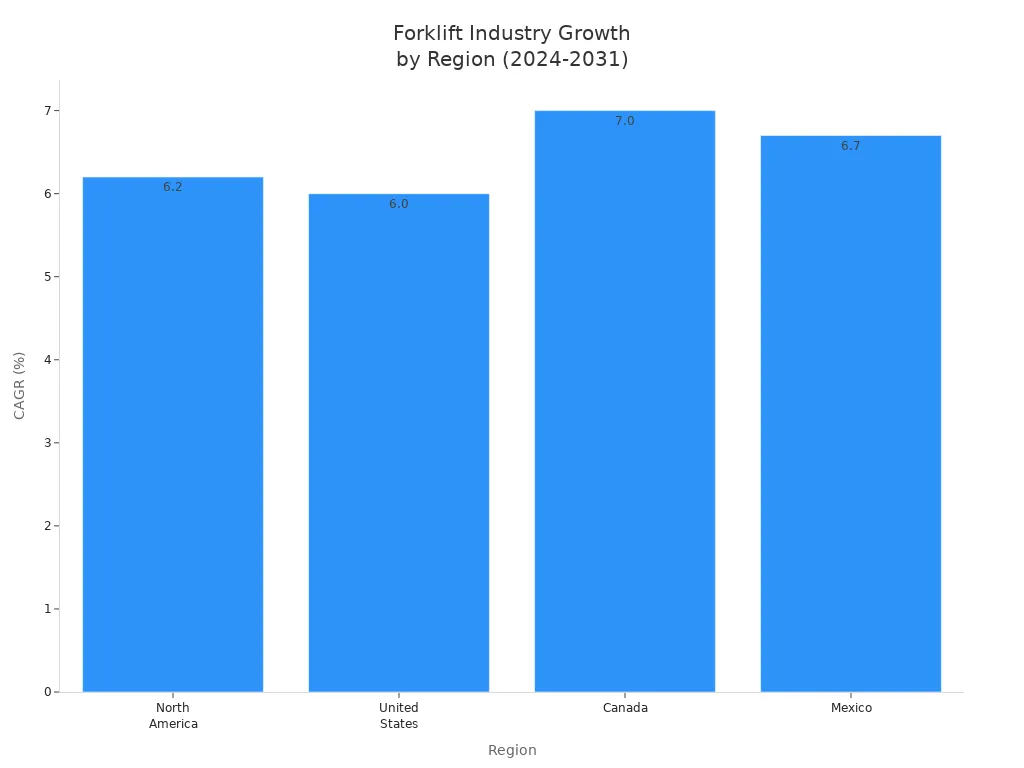

Different places help shape the forklift industry. North America makes up about 40% of the world’s forklift sales in 2024. The United States is the biggest market, worth $18,668.43 million. Canada and Mexico are also growing fast. This is because more companies need better ways to move goods and use new technology.

| Region | Market Share (2024) | CAGR (2024-2031) | Key Growth Drivers |

|---|---|---|---|

| North America | ~40% of global revenue | 6.2% | SMEs, e-commerce, indoor warehouses |

| United States | USD 18,668.43 million | 6.0% | E-commerce, construction, automation |

| Canada | USD 2,839.31 million | 7.0% | Logistics, construction, advanced tech |

| Mexico | USD 2,153.14 million | 6.7% | Logistics, warehouse efficiency |

Asia Pacific is the top region for forklifts in 2024. Cities and factories are growing fast in China, India, and Southeast Asia. This helps the market get bigger. More factories, stores, and building projects need forklifts. The Middle East & Africa are also growing, mostly in moving goods and selling products.

Key Drivers

E-commerce

E-commerce is a big reason the forklift market is growing. More people shop online, so there are more warehouses. Big companies like Walmart and Tesco use smart forklifts to move lots of items. Warehouses use more robots and IoT to work faster. Good forklifts help move things quickly and keep the supply chain running well.

E-commerce companies need more advanced forklifts.

Robots in warehouses help work go faster.

Forklifts help move lots of goods in logistics.

Construction

Building new things also helps the forklift market grow. New projects need strong forklifts to move heavy stuff. More building means more forklifts are needed. Companies want safe and strong machines for hard jobs. The market makes new designs and better forklifts for these needs.

Note: The future of forklifts depends on how well companies can change with new rules and needs. Companies that buy smart forklifts and new tech will do the best.

Forklift Trends in 2025

Electrification

Lithium-Ion Batteries

Electrification is a big trend for forklifts in 2025. Many companies pick electric forklifts with lithium-ion batteries. These batteries are reliable and work well. They give steady power and last longer than old batteries. Charging is faster, so forklifts can work more shifts. Lithium-ion batteries can last up to 3,000 cycles. This is much longer than lead-acid batteries. Electric forklifts let workers charge during breaks. They do not need to swap batteries.

| Benefit/Challenge Category | Explanation |

|---|---|

| Enhanced Performance | Lithium-ion batteries give steady power and last longer. This helps forklifts work better. |

| Faster Charging | Quick charging means less waiting. Forklifts can do more work each day. |

| Longer Lifespan | Lithium batteries last 2,000-3,000 cycles. Lead-acid batteries last only 500-1,000 cycles. This means fewer replacements and lower costs. |

| Environmental Benefits | These batteries can be recycled. They have no toxic metals and make no emissions. This helps the environment. |

| Support for Multi-Shift Operations | Workers can charge batteries during breaks. This means forklifts can work all day and night. |

| Total Cost of Ownership | Lithium-ion batteries cost more at first. But they save money over time with less fixing and longer life. |

| Regulatory Compliance | Lithium-ion batteries help companies follow new safety and environmental rules. |

| Training & Safety | Workers need training to use these batteries safely. This helps them last longer. |

| Renewable Energy Integration | These batteries can use solar or wind power. This cuts down on fossil fuels and pollution. |

| Adoption Barriers | High costs, recycling problems, and the need for new training slow down adoption. |

Electric forklifts with lithium-ion batteries change how warehouses work. They run longer, are quieter, and need less fixing. These things help companies follow new rules and save money. Battery management and telematics make forklifts work even better and stop delays.

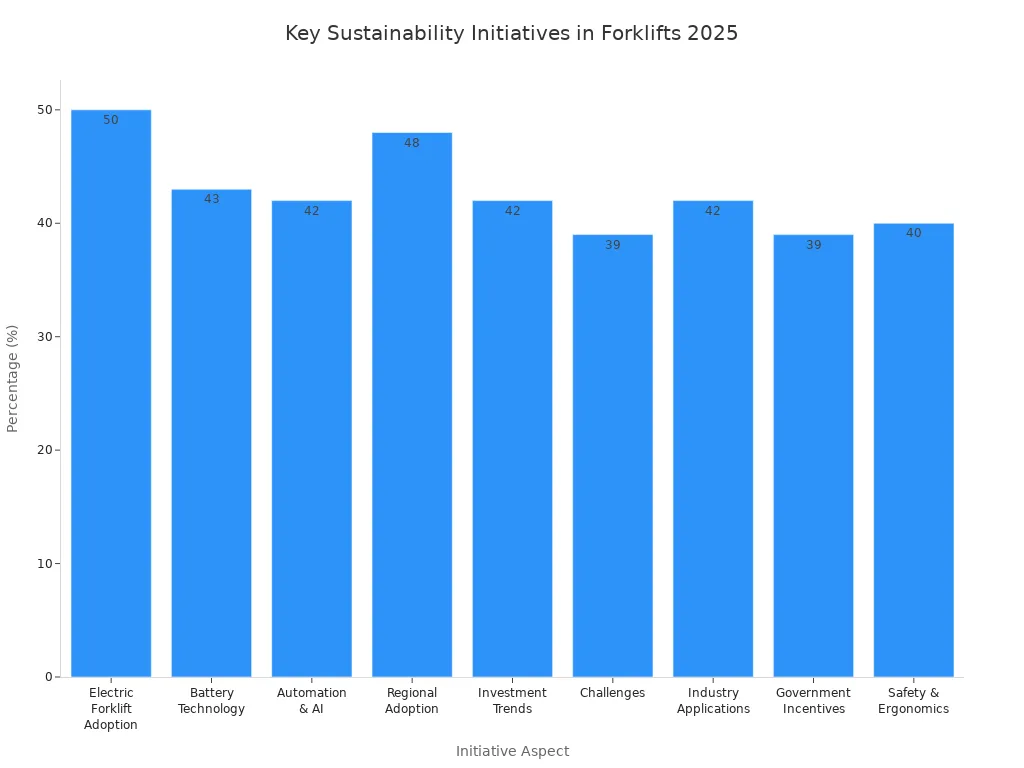

Sustainability

Sustainability is changing how forklifts are made and used. Electric forklifts do not make emissions. This makes them good for indoor jobs and packaging. They are quiet and need less fixing. This makes air cleaner and saves money. Companies use solar panels to power forklifts. This helps them get close to zero carbon emissions.

Forklift makers spend money on better batteries and automation. More companies use lithium-ion batteries. Hydrogen forklifts are also getting popular for saving energy. Government rules and rewards help companies pick green forklifts. Packaging, logistics, and factories want more eco-friendly machines. Companies start with electric forklifts in busy areas. They work with experts to make the switch easy.

Automation & AI

Automated Forklifts

Automation and AI are changing forklift work in 2025. Autonomous forklifts use LiDAR, cameras, and smart software. They move around warehouses and avoid hitting things. These forklifts learn from their surroundings. They find the best paths to move safely and quickly. Automated mobile robots are replacing old guided vehicles. They are more flexible and accurate.

AI warehouse systems guess what will be needed and plan pick routes.

Computer vision finds packaging problems and helps robots move.

IoT sensors check forklift health and warn about problems.

Autonomous forklifts talk to warehouse systems to work together.

Companies need fewer workers and make fewer mistakes. Automation helps fleets work better and faster. New rules in 2025 focus on safety and making sure machines work together safely.

Operator Assist Tech

Operator assist tech makes forklifts safer and more efficient. Systems like Hyster Reaction and Yale Reliant give real-time alerts. They use sensors to spot danger and help drivers. Forklifts can slow down or change height to stay safe.

| Feature | Safety Improvement | Efficiency Improvement |

|---|---|---|

| Lift Stability Monitoring | Sensors spot unsafe forklift moves and slow it down. This stops tip-overs. | Fewer accidents mean less downtime and smoother work. |

| Load Stability Monitoring | Sensors check if loads are stable and adjust forklift moves. | This stops damage and makes handling faster and safer. |

| Object Detection | Sensors see obstacles and stop or turn the forklift. | This avoids crashes and keeps work moving. |

| Proximity Detection | Forklifts keep safe space from people and objects. They alert drivers and others nearby. | This keeps people safe and avoids delays from accidents. |

| Location Sensing | Forklifts send their location to telematics systems. This helps follow warehouse rules. | This makes work safer and keeps things running smoothly. |

Operator assist systems help companies follow OSHA rules. They also help train workers to be safe. These tools let drivers work faster and safer. Features like overload prevention and cornering control make work safer and more efficient.

Telematics

Fleet Tracking

Telematics is important for managing forklift fleets. GPS, IoT sensors, and cloud tools track forklifts in real time. Managers can see where forklifts are and how they are used. They get alerts if something unsafe happens. Geofencing keeps forklifts in safe zones.

Telematics collects data on speed, location, and driver actions.

Managers can check fleets from anywhere using dashboards.

Usage-based billing and reports help control costs and use fleets better.

Telematics lets both small and big companies use smart fleet tools.

Predictive Maintenance

Predictive maintenance uses telematics to watch for wear and battery health. Sensors warn before something breaks. This cuts downtime and helps forklifts last longer. Real-time reports help with safety and make workers more responsible. Companies save money and use fleets better.

Fleet automation helps managers fix problems before they get worse. Predictive maintenance and telematics show results fast by stopping breakdowns. These forklift trends help companies work better, safer, and smarter.

VR & AR Training

Operator Training

Virtual reality and augmented reality change forklift training in 2025. Companies use VR to make lifelike places for practice. Operators can lift, move, and stack in these digital worlds. They face hard tasks like tight spots and dark areas. Crowded spaces are also part of the training. Operators learn by doing, which helps them remember skills. VR lets them make mistakes without real danger. This makes training safer and lowers risk.

Operators use VR headsets and laptops to learn anywhere. They do not need real forklifts or special rooms. The system gives feedback right away and tracks how they do. Trainers can change lessons for each person. VR training has a 3D warehouse and sit-down forklift models. The forklifts act like real ones. Operators try lifting, tilting, and moving loads with different forks. The system works with HTC Vive and has a replay tool. Companies can control who trains and check progress online. This makes it easy to train big teams.

Safety Simulations

VR safety training gets operators ready for real dangers. The system can show risky things like people walking by or loads that might fall. It can also show emergency stops. Operators practice what to do in these cases. This helps them remember safety rules. VR safety training saves money because it needs less real equipment and space.

Tip: VR and AR training help companies keep workers safe and skilled. These tools help workers learn better and match new forklift training trends.

Ergonomics & Comfort

Design Innovations

Forklift makers add new features to help operators feel better at work. Seats can be changed for height, tilt, and back support. Good seat springs stop bumps and shakes from rough ground. Heated and cooled seats help in hot or cold weather.

Controls are close to where arms rest, so it is easier to use them. Smaller masts and better lights help operators see more. Cameras and sensors help them notice things around them. This helps in tight spaces and keeps them safe. Mast control systems stop shaking when lifting or lowering. This makes moves more exact and less tiring. Some forklifts can be run from far away. This lets operators work from comfy spots and get less tired.

Seats adjust for comfort and back support

Seats have good springs for rough ground

Heated and cooled seat choices

Controls are easy to reach

Better lights and smaller masts for seeing more

Cameras and sensors help spot things

Mast control helps with careful moves

Can run forklifts from far away

Pick stand-up or sit-down forklifts for the job

Hyster forklifts have comfy seats and mirrors you can see without turning your head. Controls are close to your arms. These things help operators work longer with less stress.

Productivity Impact

Better comfort helps operators work longer and stay focused. Less strain means fewer injuries and less time off. Good visibility and awareness help move electric forklifts safely. This is important in busy warehouses. Companies have fewer accidents and less lost time. This helps them work better and safer. These changes make workplaces safer and more productive.

Forklift Trucks Market Outlook

Attachments Market

Specialized Capabilities

The forklift trucks market will grow in 2025. Attachments are a big part of this growth. Companies want equipment that can do many jobs. Fork positioners help workers move pallets of different sizes. This makes work safer and faster in factories and car plants. Rotators are used more in food and drink companies. They help turn loads and save money on labor. Clamps are popular in warehouses and stores. They let workers move things that are not on pallets. Other attachments like push-pulls and multi-pallet handlers help with special jobs in shipping and building. These new tools show that companies want machines that can change and do more.

Note: Special attachments help companies work safer and faster. They also help meet new rules and automation needs.

Market Growth

The forklift truck and attachments markets keep getting bigger. The attachments market could be worth $5.8 billion in 2025. By 2035, it may reach $10.7 billion. The growth rate is about 6.3% each year. Side shifters and counterbalance forklifts are growing fast too. Their growth is more than 6%. Asia Pacific and Latin America help the market grow. This is because more factories and buildings are being made. The whole forklift market may grow by $26.88 billion from 2025 to 2029. This is helped by more building projects and new technology like artificial intelligence.

| Metric | Value |

|---|---|

| Forklift Attachments Market Size in 2025 | USD 5.8 billion |

| Projected Market Size in 2035 | USD 10.7 billion |

| CAGR (2025 to 2035) | 6.3% |

New ideas like quick setup, better design, and smart features help companies solve problems. Smart attachments use sensors and AI to make work safer and stop delays. These changes help companies follow new rules.

Buyer Priorities

Reliability

People who buy forklift trucks want them to last long. They need strong machines for tough jobs. Lift height and how much weight they can carry are important. Companies pick forklifts based on power type. Some need electric for inside, others need gas for outside. Good service and support matter a lot. Buyers want machines that do not break often and have good help after buying. Some buy new forklifts with new tech and warranty. Others buy used ones to save money.

Buyers care about total cost, like fixing, energy, and downtime.

88% of buyers think good service is as important as the machine.

Service & Innovation

Service and new ideas help buyers choose forklifts. Buyers want safety features like auto brakes and easy controls. Telematics lets companies watch forklifts and fix problems fast. Lithium-ion batteries charge quickly and last longer. This helps companies work better in the future. Comfortable seats and simple controls help workers do more and get less tired. Companies can lease or rent forklifts to save money.

The forklift market is changing. Price is not the only thing that matters now. Companies want machines with new tech and good service. They spend money on things that help them work safer and smarter. Digital tools, automation, and green ideas are now very important. Innovation and making machines fit each job matter more than price.

Forklift Regulations 2025

Safety Standards

Operator Protocols

Forklift safety rules in 2025 try to stop injuries and deaths at work. Operators must follow strict steps to meet safety laws. OSHA says no one under 18 or untrained can drive a forklift. Operators must finish training about load limits, safe driving, daily checks, seat belts, safety gear, and spotting dangers. They need to know about forklift balance, the center of gravity, and how tip-overs happen.

Operators get checked at least every three years.

They need new training after accidents, unsafe acts, equipment changes, or new work areas.

Operators must check controls, brakes, steering, mast, forks, fluids, tires, attachments, and their seat before each shift.

They must write down and fix any problems before using the forklift.

Supervisors keep records and check if operators are qualified.

In 2023, forklifts caused 67 deaths at work. Almost 25,000 workers got hurt and missed work between 2021 and 2022. These facts show why rules and training are important.

Technology helps companies follow the rules. Forklift telematics and digital checklists watch forklift health and how operators act. These tools help keep workers safe and help companies follow the law.

Equipment Features

In 2025, all forklifts must have certain safety parts. Makers must approve any changes that affect how much a forklift can lift. New plates must show the right specs after changes. If old changes were not recorded, companies must get approval and update the plates.

Key safety parts include:

Seat belts and operator restraints

Overhead guards and load backrests

Warning lights and alarms

Mirrors and cameras for better sight

Stability control systems

A table below shows the safety parts and what they do:

| Safety Equipment | Function |

|---|---|

| Seat Belts | Stop the driver from being thrown out |

| Overhead Guards | Protect from things falling |

| Warning Lights/Alarms | Warn others when the forklift moves |

| Mirrors/Cameras | Help drivers see better |

| Stability Controls | Lower the chance of tipping over |

Digital records are now allowed. Companies can use computers for inspection and repair records if they are correct, have dates, and are easy to find. Supervisors must make sure all records are complete. Not following these rules can mean fines and more risk.

Emissions Compliance

Environmental Mandates

Emissions rules are now very important for forklifts. Tougher laws mean companies must stop using most gas forklifts, especially in California. The California Air Resources Board made the Zero Emission Forklift rule for Class IV and V forklifts under 12,000 lbs. This rule stops new gas forklifts and sets dates to retire old ones by engine year.

Companies must check their fleets for forklifts that do not meet the rules.

They must add charging stations and upgrade electric panels for electric forklifts.

Some forklifts, like rough-terrain or farm models, do not have to follow these rules.

In 2025, a deal paused the Zero-Emission Forklift rule in California. Dealers can still sell and companies can use gas forklifts, including LPG and dual-fuel, until at least 2026. But CARB still wants companies to use electric forklifts to help the environment. Other states like Oregon and Colorado may still use these rules.

Companies that plan early can update their fleets, cut emissions, and meet green goals. Not following the rules can mean fines and work problems.

Reporting

New emissions rules say companies must report on their forklift fleets every year. Reports must list forklift types, engine years, and if they meet the rules. Digital tools help track and organize this data. Good reports help companies follow the law and get rewards for using electric forklifts.

Reports must show fleet checks, upgrades, and when they will meet the rules.

Companies should keep notes on which forklifts are exempt or have extra time.

Using digital systems for training, checks, and repairs helps keep workers safe.

Operator Certification

Training Requirements

Operator certification is still a key forklift rule. OSHA says all drivers, even part-time or temp workers, must finish classroom lessons, hands-on training, and a test. A driver’s license does not count as forklift certification.

Training must teach:

How to use and control forklifts

How to load and unload safely

Safety steps and OSHA rules

How to check and care for equipment

Operators must be at least 18 years old. They can get certified at trade schools, online, or at work. Online classes have lessons, quizzes, and a final test. All training must follow OSHA rules.

Certification records must have the operator’s name, date, trainer’s info, and forklift type. Companies must keep these records for at least three years and be able to find them easily.

Ongoing Education

Ongoing learning keeps operators up to date with safety and new equipment. Operators must get recertified every three years or sooner after an accident, unsafe act, or job change. Training must fit the workplace and forklift, covering controls, safety, load handling, environment, and site dangers.

Refresher training is needed after accidents or unsafe acts.

Operators must check equipment before each shift and follow safety rules.

Supervisors must check if operators are qualified and keep records up to date.

Tip: Spending on ongoing training and digital records helps companies follow the rules and lower risks.

Speed & Usage Guidelines

Industry Recommendations

Experts give clear rules for using forklifts at work. These rules help keep workers safe and stop accidents. Operators must check forklifts every day before use. This makes sure the forklift works right and does not break down.

Operators must never go over load limits. Too much weight can make the forklift tip over. Most companies set speed limits for each area. In open spaces, the top speed is 8 mph. In busy areas, the speed drops to 3 mph. Employers must put up signs and watch speeds.

Operators should slow down on rough floors or ramps.

Heavy or high loads mean driving even slower.

Slow down before turns and take wide paths.

Keep loads low for better balance.

At crossings, use the horn, follow speed signs, and leave space to stop.

Employers must train workers, check forklifts, and make sure rules are followed.

A good safety plan uses marked paths, clear signs, and checks on how people act. OSHA says operators need training and must get certified every three years. These steps help companies follow the law and keep workers safe.

Workplace Safety

Driving too fast on a forklift is dangerous. High speeds can cause tip-overs and crashes. These accidents hurt people and can even cause deaths. If drivers go too fast, they cannot stop in time. This can hurt people, break things, and get the company in trouble.

Employers must keep work safe but also get jobs done. They should think about the forklift type and how the area is set up. Wet floors or ramps mean drivers must go slower. Companies must stop unsafe moves like sharp turns or quick starts. They do this with speed signs, watching drivers, and more training.

Operators must look for dangers before moving.

Employers can use digital tools to watch speed and use.

Giving feedback and coaching helps drivers get better.

A safe workplace needs everyone to follow the rules. When companies set clear rules and check them, accidents go down and workers stay safe.

Adapting to Forklift Industry Changes

Technology Investment

ROI Assessment

Companies need to check if new forklift technology is worth the money. They should look at how much profit they get from working faster and saving money. Then, they compare this to what they spend to buy, run, and keep the forklifts working. The formula is:

ROI = (Net profit from using forklift – Total investment and operating costs) / Total investment and operating costs x 100%

Main costs are buying, setting up, training, energy, fixing, and storing forklifts. The good things are working faster, paying less for workers, and using space better. Electric forklifts can save money on fuel and repairs. This makes them cheaper to own over time. Companies should also use tools like Payback Period and Net Present Value to help choose. Before buying, they must know what they need, check different sellers, and think about help after buying.

Implementation

To use new technology well, companies must know what they need. They should:

Check how much they lift, how wide aisles are, and where they work.

Talk to equipment sellers early to make sure things fit.

Ask for demos at their site to try new features.

Train workers with VR or real practice.

Use fleet systems to watch how forklifts are used and fixed.

Automated Guided Vehicles and driver-assist tech help stop mistakes and keep people safe. Trying new tech in small steps lets teams learn before using it everywhere. Using data and feedback helps companies get better all the time.

Workforce Training

Upskilling

Training workers is important as forklifts change. Upskilling teaches workers to use automation, robots, and AI systems. On-the-job and certification classes help workers learn without stopping work. Digital tools like VR and AR make learning easier and more fun. Small certificates and flexible classes help workers learn new things fast.

Certification classes make sure workers know safety and rules.

Temp-to-hire helps find workers who can learn tech jobs.

Working with apprentice programs helps grow the team for the future.

Safety Culture

A good safety culture keeps people and forklifts safe. Companies should:

Give safety classes often and repeat them.

Use telematics and dashboards to watch how drivers work.

Give quick coaching to workers who need help.

Make safety important for everyone, not just a rule.

Operator assist systems like stability controls help stop accidents and make work safer.

Maintenance Strategies

Predictive vs. Preventive

Modern maintenance uses both predictive and preventive ways. Predictive maintenance uses sensors and real-time data to watch forklifts and guess when they might break. This helps stop long waits and saves money on repairs. Preventive maintenance means checking and fixing forklifts on a schedule to stop problems and follow rules. Using both ways with digital fleet tools helps companies the most.

Lifecycle Management

Good lifecycle management helps forklifts last longer and saves money. Companies should:

Plan maintenance by how much forklifts are used and by the calendar.

Use skilled workers and keep spare parts ready.

Study maintenance data to find patterns and plan fixes early.

AI telematics help companies see problems before they get big, so forklifts work better and longer.

Tip: Spending on predictive maintenance and worker training helps companies keep up with changes and stay ahead of others.

Compliance Management

Monitoring Updates

Businesses must follow new rules in the forklift industry. These rules can change safety, emissions, and training. Companies that watch for updates avoid mistakes and fines. Many use digital tools to track rule changes and stay compliant.

AI-powered systems like Visionify help companies spot safety issues fast. These systems send alerts if workers go into restricted zones. They also warn if workers do not wear safety gear. The systems count how many people are in an area. They track how long workers stay near hazards. Managers can fix problems quickly and keep everyone safe.

Forklift simulator training software helps with compliance too. These programs follow OSHA standards and update when rules change. Operators train in virtual reality to get ready for real risks. Companies can update training content quickly. Workers always learn the newest safety steps.

Powerfleet gives another way to manage compliance. Their platform tracks licenses and certifications automatically. It reminds managers when renewals are needed. No one drives with an expired license. The system checks company practices against local and global rules. This helps businesses find gaps and fix them before inspectors come.

Key steps for monitoring updates include:

Use AI systems to spot safety and compliance issues fast.

Track worker movements and PPE use to meet safety rules.

Update training programs quickly for new regulations.

Automate license and certification tracking to avoid problems.

Check company practices against current laws and standards.

Tip: Digital compliance tools help companies change quickly and lower the risk of breaking rules.

Industry Engagement

Staying connected with industry groups helps companies learn new rules early. These groups share updates, best practices, and training resources. They also let members help shape future regulations.

Companies join groups like the Industrial Truck Association or safety councils. These groups hold meetings, webinars, and workshops. Members learn about new laws, technology trends, and safety tips. They also meet other workers and experts.

Active engagement brings many benefits:

Early access to rule updates and industry news.

Chances to join pilot programs for new tech or safety standards.

Expert advice on compliance problems.

Sharing best practices with other companies.

Influence over future rules through feedback and advocacy.

A table below shows how industry engagement helps compliance:

| Engagement Activity | Compliance Benefit |

|---|---|

| Attend industry webinars | Learn about new rules and trends |

| Join safety councils | Get expert advice and resources |

| Participate in pilot tests | Prepare for upcoming regulations |

| Share best practices | Improve company compliance strategies |

Note: Companies active in industry groups respond faster to changes and build a safer workplace.

The forklift industry is changing quickly in 2025. Companies notice new things like electrification and automation. There are also more safety rules now. Businesses that change early can follow the rules and do well. Leaders should buy new technology and teach workers how to use it. They should also look at their maintenance plans often. Checking for new rules helps keep everyone safe and work running smoothly.

If companies learn about changes and get ready, they will do better in the forklift market.

FAQ

What are the main forklift trends for 2025?

Electrification, automation, telematics, and ergonomic design are big trends. Companies pick electric forklifts to lower pollution. Automated systems and telematics make work safer and faster. Ergonomic features help operators work longer without getting too tired.

How do new forklift regulations affect businesses?

New rules mean companies must do more safety checks and train operators. They also have to report emissions and keep digital records. Following the rules early helps companies avoid fines and keeps workers safe.

Why do companies invest in lithium-ion batteries?

Lithium-ion batteries last longer and charge faster than lead-acid ones. They help cut down on waiting and fixing costs. Many companies use them to meet green rules and work more shifts.

What is predictive maintenance for forklifts?

Predictive maintenance uses sensors and telematics to watch forklift health. The system warns managers before something breaks. This saves money on repairs and keeps forklifts working well.

How does VR training improve forklift safety?

VR training lets workers practice in a digital warehouse. They learn skills and safety steps in real-life situations. This lowers accident risks and helps workers remember what to do.

What are the benefits of joining industry groups?

Industry groups give early news about rules and trends. Members get expert help, training, and chances to meet others. Companies can learn fast and handle changes better.

Are there incentives for switching to electric forklifts?

Some states give grants or tax credits for electric forklifts. These help companies pay for upgrades. Businesses also save on fuel and follow emissions rules more easily.

How often must forklift operators get recertified?

Operators need to get recertified every three years. More training is needed after accidents, unsafe acts, or equipment changes. Regular training keeps operators up to date with safety rules.

English

English