AUGUST 21, 2025

How Heavy Is A Forklift Truck

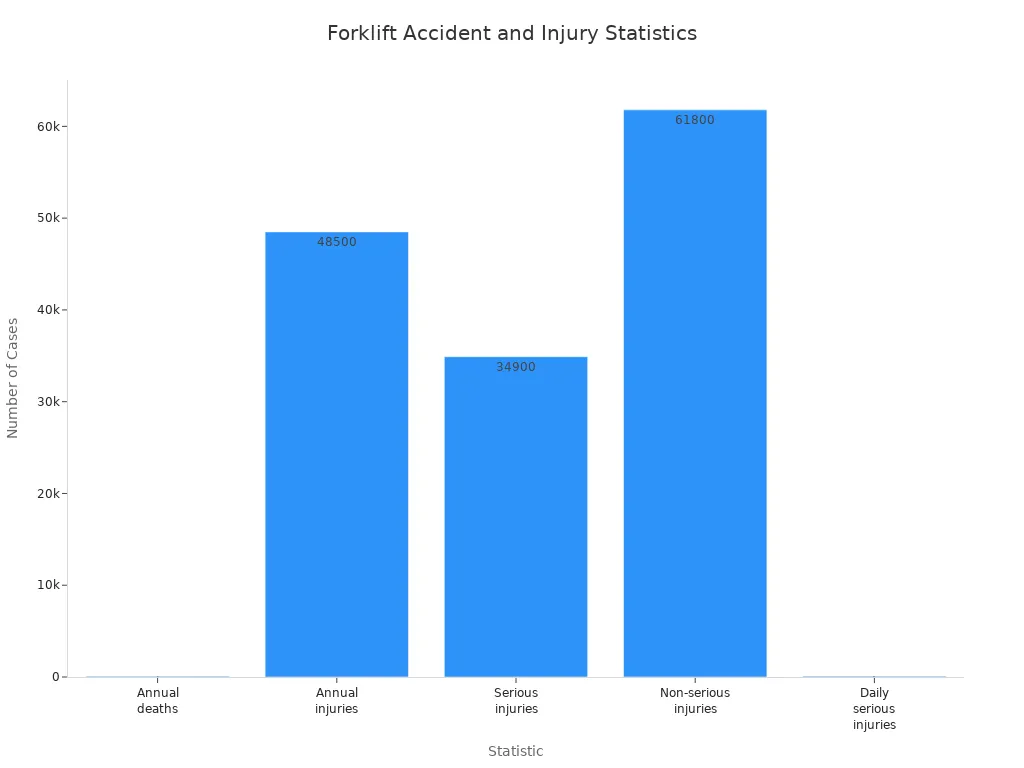

A forklift truck can weigh from 3,000 pounds to over 140,000 pounds. Some models, like the Donkey 3K “Burro,” are much lighter. Super heavy Kalmar trucks are the heaviest and can lift the most. Most forklifts weigh about 9,000 pounds. This is almost three times heavier than a regular car. Knowing how much a forklift weighs is important for safety. If you do not handle forklifts the right way, accidents can happen. Many people get hurt at work each year because of this.

Key Takeaways

Forklift trucks can weigh from 3,000 to 140,000 pounds. Most regular forklifts weigh about 8,000 to 9,000 pounds. Forklifts are heavier than what they can lift. This helps keep them steady and stops them from tipping over. Operators must look at the forklift’s data plate before using it. The data plate shows the exact weight and safe lifting limits. Picking the right forklift is important for safety. You need to think about weight, lifting capacity, floor strength, and the work area. Using forklifts the right way and knowing their weight helps stop accidents. It also protects floors and keeps work running smoothly.

How Much Does a Forklift Weigh

Average Forklift Weight

Forklift weight varies a lot depending on the model and its lifting capacity. Most standard forklift trucks weigh between 6,000 and 9,000 pounds. This makes them much heavier than a typical passenger car, which usually weighs about 3,000 pounds. The average forklift weight is about 8,245 pounds, based on recent industry data. This weight includes the counterweight, which helps keep the forklift stable when lifting heavy loads.

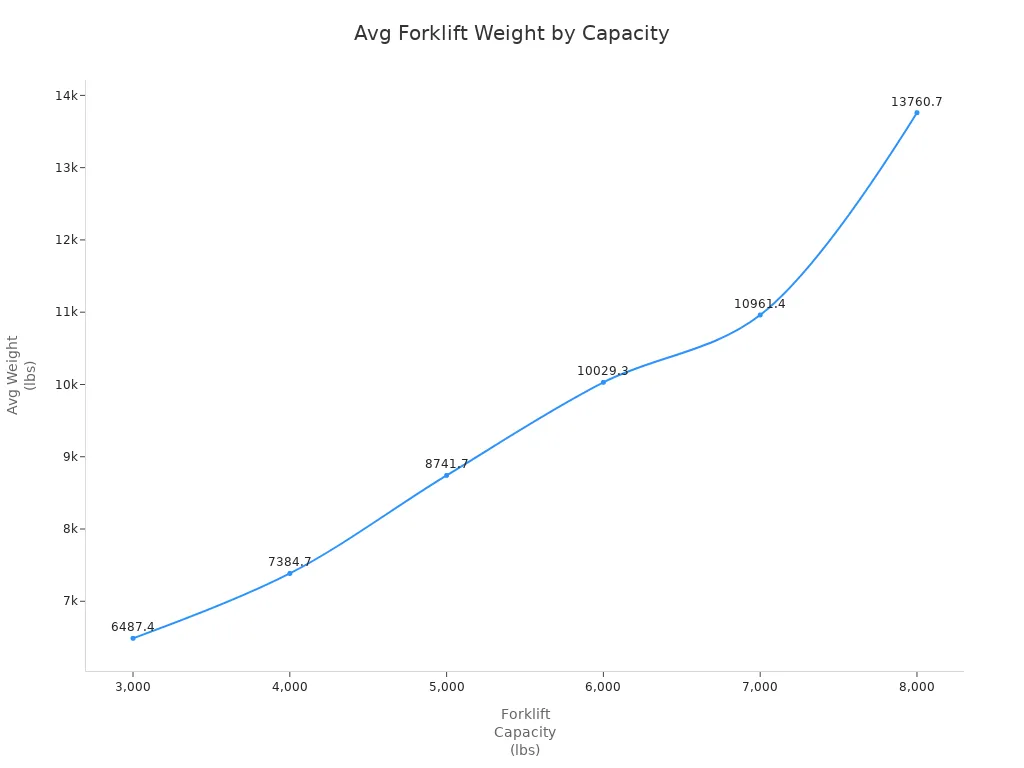

The table below shows how much a forklift weighs at different lifting capacities:

| Forklift Capacity (lbs) | Average Weight (lbs) | Number of Models Analyzed |

|---|---|---|

| 3,000 | 6,487.4 | 105 |

| 4,000 | 7,384.7 | 132 |

| 5,000 | 8,741.7 | 109 |

| 6,000 | 10,029.3 | 97 |

| 7,000 | 10,961.4 | 19 |

| 8,000 | 13,760.7 | 49 |

The chart below shows how forklift weight increases as lifting capacity goes up:

A forklift with a 5,000-pound lifting capacity usually weighs between 8,000 and 9,000 pounds. This extra weight helps the forklift stay balanced when carrying heavy loads. When people ask, “how much does a 3000 lb forklift weigh,” the answer is about 6,500 pounds. For those wondering “how much does a 4000 lb forklift weigh,” it is close to 7,400 pounds. A 6,000-pound capacity forklift weighs about 10,000 pounds, while a 7,000-pound capacity model weighs nearly 11,000 pounds. If someone asks, “how much does a 8000 lb forklift weigh,” the answer is almost 14,000 pounds. These numbers show that forklift weight always exceeds the lifting capacity for safety.

A 3-ton forklift, which is about 6,000 pounds of lifting capacity, weighs around 10,000 pounds. People often ask, “how much does a small forklift weigh?” Smaller models, like electric or compact forklifts, can weigh as little as 3,000 pounds, but most weigh more to provide stability.

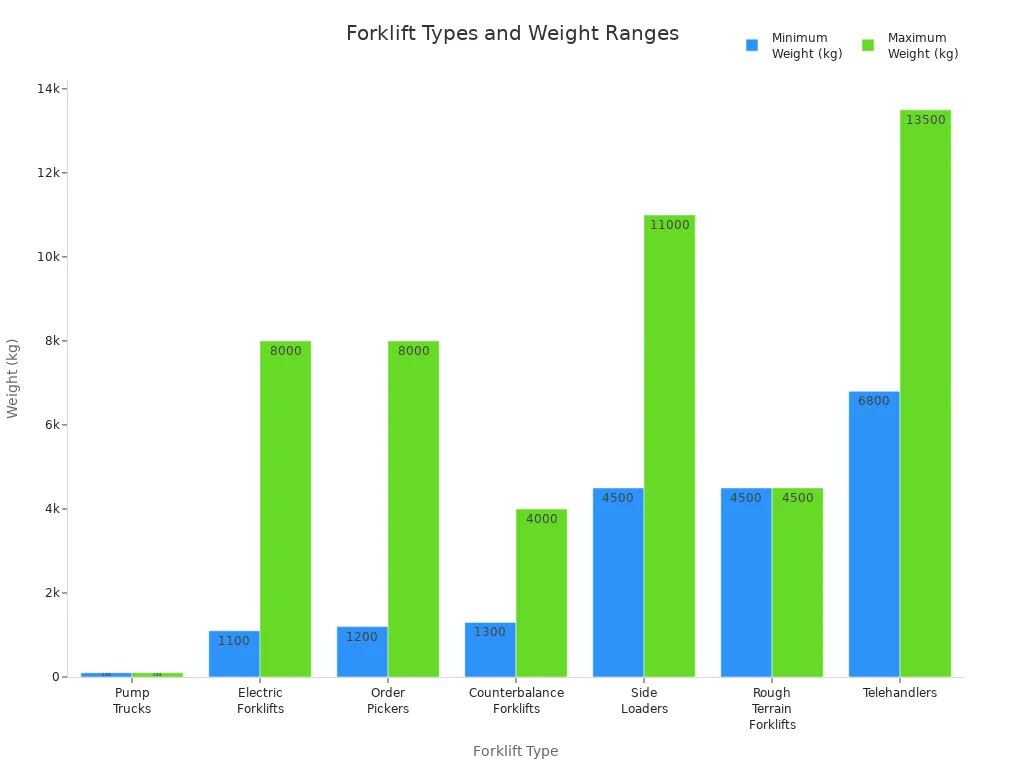

Weight Range by Type

Forklift trucks come in many types, and each type has its own weight range. The lightest models are pump trucks, which weigh about 100 kilograms (220 pounds). Order pickers and electric forklifts range from 1,100 to 8,000 kilograms (2,400 to 17,600 pounds). Counterbalance forklifts, which are common in warehouses, weigh between 1,300 and 4,000 kilograms (2,900 to 8,800 pounds). Side loaders and rough terrain forklifts are heavier, starting at 4,500 kilograms (9,900 pounds). Telehandlers, which are a type of heavy duty forklift, can weigh over 13,500 kilograms (29,700 pounds).

Here is a table showing the weight ranges for different forklift types:

| Forklift Type | Weight Range (kg) |

|---|---|

| Pump Trucks | ~100 |

| Order Pickers | 1,200 – 8,000 |

| Electric Forklifts | 1,100 – 8,000 |

| Counterbalance Forklifts | ~1,300 – 4,000 |

| Side Loaders | 4,500 – 11,000 |

| Rough Terrain Forklifts | Starting at 4,500 |

| Telehandlers | 6,800 – 13,500+ |

Large forklift trucks, such as rough terrain models and telehandlers, weigh much more than standard warehouse forklifts. Big forklift models used in ports or heavy industry can weigh over 140,000 pounds. These heavy machines are designed to lift very large loads safely. When choosing a forklift truck, knowing the forklift weight helps ensure the right equipment is used for the job and that the floor can support the load.

Forklift Weight by Type

Electric Forklifts

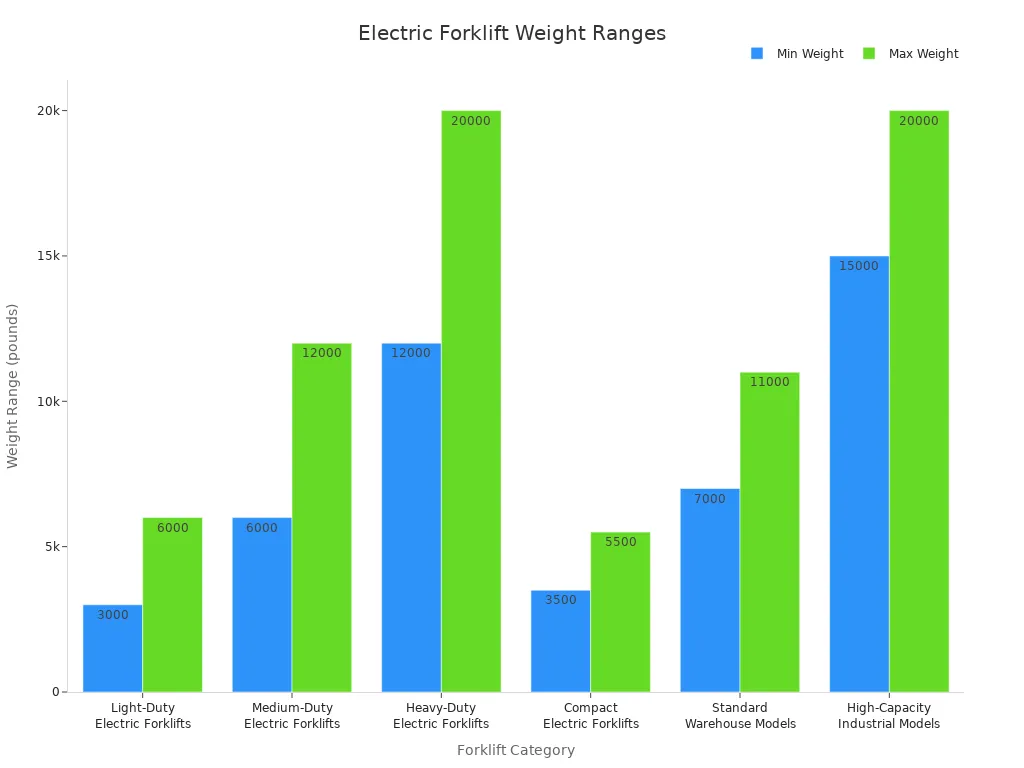

Electric forklifts can be light or heavy. Light-duty electric forklifts weigh 3,000 to 6,000 pounds. These are good for small spaces and weak floors. Medium-duty electric forklifts weigh 6,000 to 12,000 pounds. They are strong but still easy to move. Heavy-duty electric forklifts weigh 12,000 pounds or more. These lift big loads in factories. Some compact electric forklifts weigh 3,500 to 5,500 pounds. Standard warehouse models weigh 7,000 to 11,000 pounds. The biggest electric forklifts can weigh over 15,000 pounds.

| Electric Forklift Category | Weight Range (pounds) | Typical Lifting Capacity (pounds) | Description / Use Case |

|---|---|---|---|

| Light-Duty Electric Forklifts | 3,000 - 6,000 | Up to 5,000 | Compact, maneuverable, suitable for tight warehouse spaces and weight-sensitive floors |

| Medium-Duty Electric Forklifts | 6,000 - 12,000 | 5,000 - 10,000 | Common in warehouses, balance of capacity and maneuverability |

| Heavy-Duty Electric Forklifts | 12,000 - 20,000+ | Over 15,000 | Industrial, heavy lifting, less maneuverable but very stable |

| Compact Electric Forklifts (models) | 3,500 - 5,500 | N/A | Three-wheel designs, prioritize maneuverability |

| Standard Warehouse Models | 7,000 - 11,000 | N/A | Four-wheel forklifts for general warehouse use |

| High-Capacity Industrial Models | 15,000+ | N/A | Heavy industrial use, maximum lifting capacity and durability |

Counterbalance Forklifts

Counterbalance forklifts are used in many warehouses. Most weigh between 4,000 and 8,800 pounds. Some special ones can weigh up to 11,000 pounds. These forklifts have a counterweight in the back. This helps them stay balanced when lifting. They are good for moving pallets and stacking boxes. Their weight makes them useful in both small and big warehouses.

Rough Terrain Forklifts

Rough terrain forklifts are much heavier than regular ones. Most weigh 5,000 to 15,000 pounds. Some heavy duty forklifts can weigh up to 90,000 pounds. These work outside on rough ground. They carry heavy things at building sites and lumber yards. Small rough terrain forklifts start at 1,000 to 2,000 pounds. Most industrial models weigh 3,000 to 15,000 pounds. The biggest rough terrain forklifts, like the Kalmar Super Heavy Forklift Truck DCG600-850, weigh 215,000 pounds. This huge forklift can lift up to 187,000 pounds. It is the heaviest forklift truck you can find.

Note: Forklift weight changes by type, size, and job. Electric forklifts are usually the lightest. Big forklift trucks like the Kalmar DCG600-850 are the heaviest.

Forklift Truck Models and Weights

Model Comparison Table

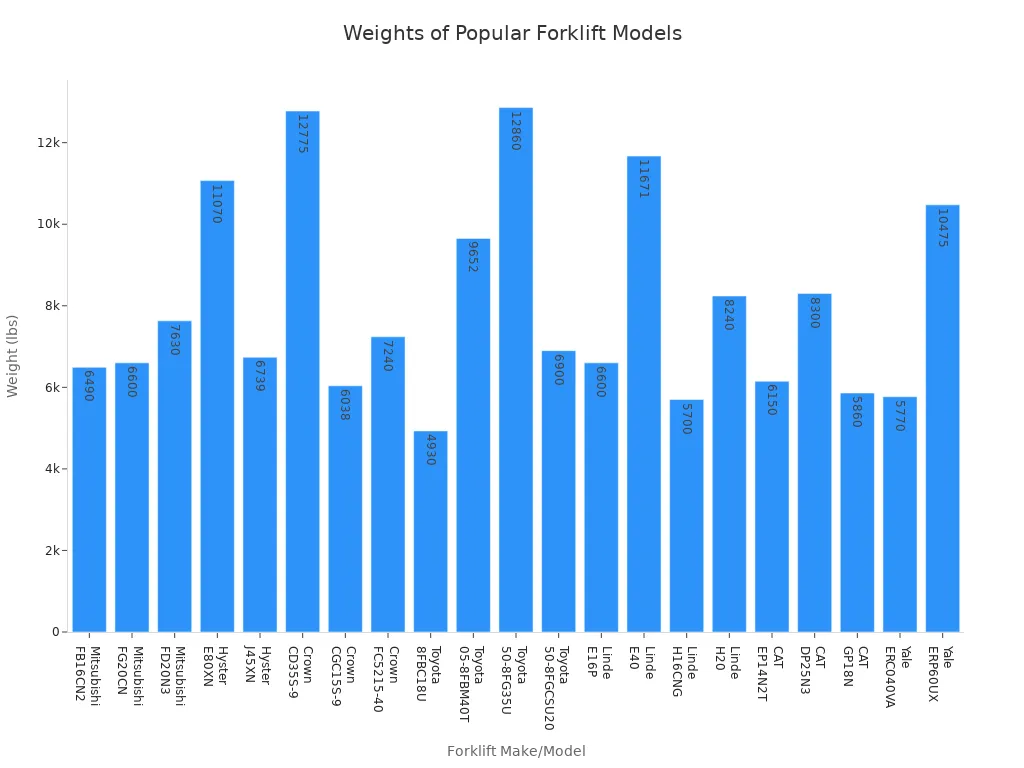

Forklift weight changes a lot by brand. Each company builds models for different jobs. This means weights are not always the same, even if lifting power matches. The table below lists popular forklift models. It shows their types, how much they can lift, and how much they weigh. This helps buyers and workers know the weight for each brand and model.

| Forklift Make/Model | Type of Forklift | Capacity (lbs) | Weight (lbs) |

|---|---|---|---|

| Mitsubishi - FB16CN2 | Electric | 3,500 | 6,490 |

| Mitsubishi - FG20CN | LPG | 4,400 | 6,600 |

| Mitsubishi - FD20N3 | Diesel | 4,400 | 7,630 |

| Hyster - E80XN | Electric | 8,000 | 11,070 |

| Hyster - J45XN | Electric | 4,500 | 6,739 |

| Crown - CD35S-9 | LPG | 8,000 | 12,775 |

| Crown - CGC15S-9 | LPG | 3,000 | 6,038 |

| Crown - FC5215-40 | Electric | 4,000 | 7,240 |

| Toyota - 8FBC18U | Electric | 3,500 | 4,930 |

| Toyota - 05-8FBM40T | Electric | 8,000 | 9,652 |

| Toyota - 50-8FG35U | Internal Combustion | 8,000 | 12,860 |

| Toyota - 50-8FGCSU20 | Internal Combustion | 4,000 | 6,900 |

| Linde - E16P | Electric | 3,500 | 6,600 |

| Linde - E40 | Electric | 8,800 | 11,671 |

| Linde - H16CNG | LPG | 3,500 | 5,700 |

| Linde - H20 | Diesel | 4,400 | 8,240 |

| CAT - EP14N2T | Electric | 3,100 | 6,150 |

| CAT - DP25N3 | Diesel | 5,500 | 8,300 |

| CAT - GP18N | LPG | 3,850 | 5,860 |

| Yale - ERC040VA | Electric | 4,000 | 5,770 |

| Yale - ERP60UX | Electric | 6,000 | 10,475 |

Operators use this table to check forklift weight before moving it. Big forklift trucks and heavy duty models are at the top of the list. Large models like the Hyster E80XN and Linde E40 show that more lifting power means more weight.

How to Find Model Weight

Manufacturers make it easy to find forklift weight. Every forklift has a data plate near the controls. This plate is usually on the dashboard. It shows the truck’s weight, model, serial number, and other facts. For internal combustion forklifts, the plate shows the chassis weight without anything loaded. Electric forklifts show the truck weight without the battery. Operators must add the battery weight to get the total. Forklift weight can change by brand, but all makers follow OSHA and ANSI rules for labels. The plate must always be easy to read and stay on the forklift.

Tip: Always look at the data plate before using or moving a forklift. If the forklift has new parts or changes, the maker must update the plate with the new weight and safe limit.

Manufacturers test forklifts carefully to set the right weight and lifting power. They figure out the safest load by checking balance and stability. This makes sure the forklift works safely and follows all rules.

Forklift Weight vs Lifting Capacity

What Is Forklift Weight

Forklift weight means how heavy the whole forklift is. This includes every part, like the battery and any extra pieces. Forklift weight is different from lifting capacity. The weight helps the forklift stay steady when lifting things. Counterweights make the forklift heavier and stop it from tipping over. Forklift weight changes with the type, model, size, and fuel. Electric forklifts have heavy batteries that add more weight. Operators need to know the forklift weight. This helps them check if the floor can hold the forklift and plan safe moves.

What Is Lifting Capacity

Lifting capacity shows how much weight a forklift can lift safely. Makers measure lifting capacity at a set spot called the load center. The load center is the space from the forks to the middle of the load. The data plate on the forklift shows the lifting capacity at a 24-inch load center. The real lifting capacity can be less if the load is bigger or if there are attachments. The chart on the data plate shows the most weight the forklift can lift at different heights and load centers. Operators should always look at these charts before lifting.

Lifting capacity depends on:

Load center distance

Forklift size

Attachments and their weight

How high you lift

Forklift condition

Note: OSHA and ANSI rules say every forklift needs a data plate. The plate must show lifting capacity and any changes if attachments are added.

Why the Difference Matters

Forklift weight and lifting capacity are not the same. Forklift weight is the whole machine. Lifting capacity is the safe limit for lifting things. The difference comes from things like counterweights, frame size, and attachments. Attachments like sideshifters add weight and change the load center. This lowers how much the forklift can lift. Lifting loads higher also lowers the safe lifting capacity because the center of gravity moves. The forklift can lift less if the load is long or uneven. Tire type and battery weight also change how steady the forklift is and how much it can lift. Operators need to know these differences. This helps stop tipping accidents and helps pick the right forklift for each job. Using the wrong forklift or ignoring the lifting limit can be unsafe and cause damage.

Why Forklift Weight Matters

Safety and Stability

Forklift weight is important for keeping the machine steady. Safety rules say stability depends on where the load sits. The center of gravity also matters a lot. Operators must keep the load within the lifting limit. The load should be in the middle of the forks. If the load is too heavy or too far forward, the center of gravity moves. This can make the forklift tip over. The stability triangle shows this risk. If the center of gravity moves outside the triangle, the forklift is not stable. Operators should:

Never lift more than the rated capacity.

Keep loads in the middle and near the front wheels.

Move slowly and keep the load low when driving.

Watch for loads that are uneven or not balanced.

Some new operators think forklifts can lift more than they should. This is not true. Lifting too much or placing loads wrong can cause accidents.

Floor and Transport

Forklift weight affects what kind of floor it can drive on. Heavy forklifts need strong floors. For example, a 6-inch concrete slab with rebar can hold forklifts up to 58,000 pounds. Most concrete floors can take about 500 psi. Forklifts with a full load can put up to 350 psi on the front tires. This does not leave much extra safety room. Facility managers must check the floor strength before using big forklifts. The table below shows safe limits:

| Parameter | Limit |

|---|---|

| Front axle load (forklift + load) | 5,460 kg max |

| Minimum tire contact area | 142 cm² |

| Minimum tire width | 180 mm |

| Minimum wheel spacing (one axle) | 760 mm |

Moving forklifts also needs planning. The total weight of the forklift and any parts must not be more than the transport truck can carry.

Choosing the Right Forklift

Picking the right forklift means looking at more than just how much it can lift. Operators and managers should think about:

The usual and biggest loads.

The type of ground, like smooth floors or rough outdoor areas.

How high things need to be lifted.

The size and shape of loads and any special parts.

The warehouse layout, like aisle width and shelf height.

The fuel type, such as electric for inside or diesel for outside.

Safety features and how easy it is to fix.

Choosing the right forklift weight and lifting power helps stop accidents and damage. Operators should always check the data plate and follow the maker’s rules. Good training and regular checks keep work safe and smooth.

Forklift truck weights can be very different. Here are some examples:

| Forklift Type/Product | Weight/Load Capacity Range (tonnes) |

|---|---|

| Counterbalance forklifts (general range) | 1.8 to 48 |

| Linde E35-E50 Series 1254 electric forklift | 3.5 to 5 |

| Clark electric pallet trucks (WS and SWX) | 1.2 to 1.6 |

Operators must look at the manufacturer’s data plate before using a forklift. The data plate shows the forklift’s weight and safe limits. This helps stop accidents and follows safety rules. Knowing the right weight keeps people safe, protects the floor, and helps pick the best equipment.

FAQ

How much does a forklift weigh?

Most forklift trucks weigh between 3,000 and 140,000 pounds. The average forklift weight is about 8,000 pounds. Large forklift trucks and heavy duty forklift models can weigh much more.

Why is forklift weight important for safety?

Forklift weight helps keep the machine stable. Operators must know the weight to prevent tipping accidents. Heavy duty forklift trucks need strong floors and safe handling.

What is the difference between lifting capacity and forklift weight?

Lifting capacity shows how much a forklift can safely lift. Forklift weight means the total weight of the machine. Big forklift models have higher lifting capacity and more weight.

Where can someone find the exact weight of a forklift?

The manufacturer’s data plate shows the forklift weight. This plate sits near the controls. Operators should check it before using or moving any forklift truck.

Do big forklift trucks need special transport?

Yes, large forklift trucks and heavy duty forklift models often need special trucks for transport. Their weight can exceed regular limits. Always check the transport vehicle’s capacity.

English

English