AUGUST 21, 2025

How Much Does A Forklift Weigh?

The average forklift weighs about 9,000 pounds. Most warehouse forklifts weigh between 8,200 and 9,000 pounds. The weight depends on how much the forklift can lift. For example, a forklift that can lift 5,000 pounds usually weighs 7,500 to 10,000 pounds. The forklift weight means the real mass of the machine. It does not mean how much it can lift. Knowing this weight is important for floor safety. It also matters for ramp strength and stopping accidents.

Key Takeaways

Most forklifts weigh from 3,000 to 15,000 pounds. Warehouse forklifts usually weigh about 9,000 pounds.

The weight of a forklift depends on its size. It also depends on how much it can carry. The power source and attachments matter too. These things change how stable and safe the forklift is.

Forklift weight is not the same as lifting capacity. Weight means how heavy the machine is. Capacity means how much it can lift safely.

Always look at the forklift’s data plate or manual before using it. This tells you the exact weight and capacity. Doing this helps stop accidents and floor damage.

Knowing the forklift’s weight helps you pick the right equipment. It makes moving the forklift safer. It also keeps workers and workplaces safe.

Forklift Weight Ranges

Average Weight of a Forklift

Forklift weight varies by model, size, and use. The average weight of a forklift in a warehouse setting is about 9,000 pounds. This weight includes the machine, battery, and counterweight. The weight of the forklift helps keep it stable when lifting heavy loads. Most standard warehouse forklifts with a 5,000-pound lifting capacity weigh between 8,000 and 9,000 pounds. This is almost three times the weight of a typical car.

The service weight of a forklift is important for safety. It affects how the forklift moves and stops. It also helps prevent tipping when carrying loads.

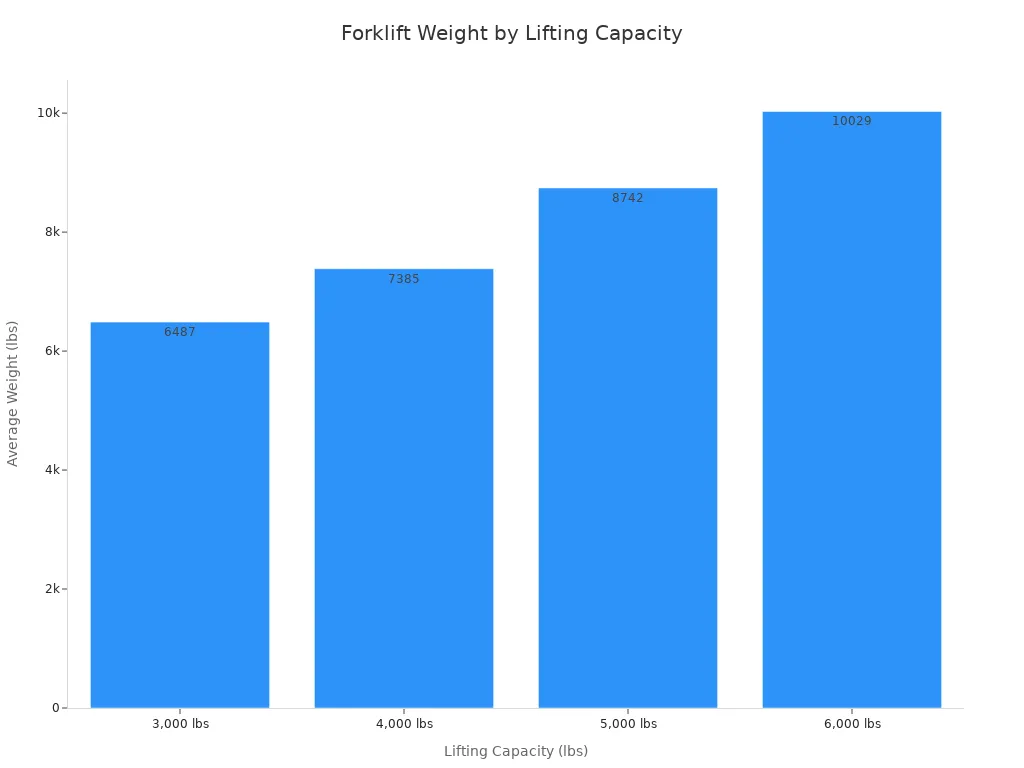

The table below shows forklift weights by model and lifting capacity:

| Lifting Capacity (lbs) | Average Weight (lbs) |

|---|---|

| 3,000 | 6,487 |

| 4,000 | 7,385 |

| 5,000 | 8,742 |

| 6,000 | 10,029 |

| Overall Average (Top 22 models) | 8,245 |

The average forklift weight for top models is about 8,245 pounds. This number gives a good idea of how heavy is a standard forklift. The weight in pounds can change based on the type and size of the forklift.

Small and Large Forklift Weights

Forklift weights by model can range from small, light-duty machines to large forklift trucks built for heavy jobs. Small electric forklifts designed for light tasks usually weigh between 3,000 and 6,000 pounds. These forklifts work well indoors and in tight spaces. The service weight of a forklift in this category is lower to reduce floor wear and save energy.

| Forklift Type | Load Capacity (lbs) | Weight Range (lbs) | Notes |

|---|---|---|---|

| Electric Forklifts | Up to 4,000 | 3,000 - 6,000 | Small, light-duty, indoor use |

| Standard Forklifts | 3,500 - 4,500 | 4,930 - 7,630 | General warehouse use |

| Mid-size Forklifts | 6,000 - 8,000 | 9,652 - 13,710 | Mixed indoor/outdoor use |

Big forklift models, such as heavy duty forklift trucks, can weigh much more. Large forklift trucks used in ports or heavy industry often weigh from 15,000 to over 100,000 pounds. These big forklift machines handle steel beams, shipping containers, and other massive loads. The weight of the forklift in these cases is much higher to provide stability and strength.

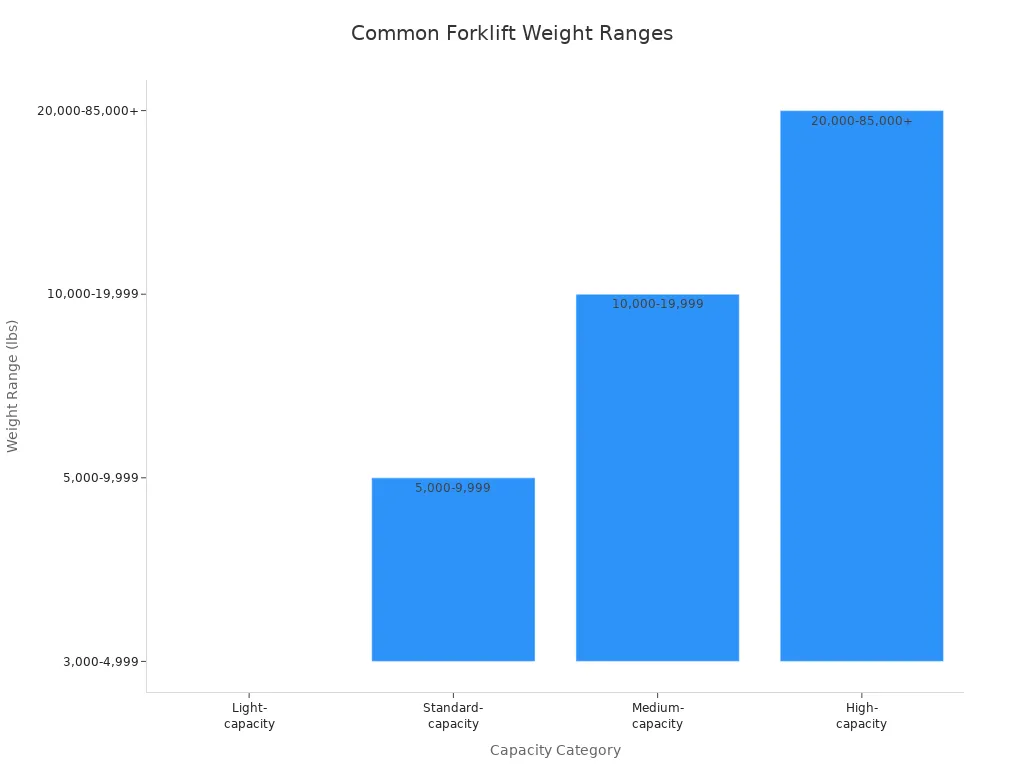

| Forklift Capacity Category | Weight Range (lbs) | Description/Use Case |

|---|---|---|

| Light-capacity | 3,000 - 4,999 | Small sit-down rider forklifts, lightweight tasks |

| Standard-capacity | 5,000 - 9,999 | Average warehouse forklifts, e.g., 5,000 lb capacity |

| Medium-capacity | 10,000 - 19,999 | Heavier lifting needs, mixed indoor/outdoor use |

| High-capacity | 20,000 and above (up to 85,000+) | Heavy-duty diesel forklifts for outdoor, high-capacity lifting |

Forklift weight depends on the type of power source. Electric forklifts are lighter and work best indoors. Propane forklifts have a moderate weight and can be used both indoors and outdoors. Diesel forklifts are the heaviest and are built for outdoor and tough jobs. The weight of the forklift also changes with the size of the counterweight, the frame, and any attachments.

Tip: Always check the forklift weights by model before moving or using them in a new area. This helps prevent floor damage and keeps everyone safe.

The average weight of a forklift gives a good starting point, but always look at the specific weight of the forklift you plan to use. Big forklift models and heavy duty forklift trucks can weigh as much as 140,000 pounds. Knowing the forklift weight helps with planning, safety, and choosing the right equipment for the job.

How Much Does a Forklift Weigh

Factors Affecting Forklift Weigh

Many things can change how much a forklift weighs. The weight depends on its size, shape, and what it is made of. Different parts and features add to the total weight. Here are the main things that matter:

Size and Structure: Bigger forklifts have wider bodies and stronger frames. These make the forklift heavier and help it lift more.

Chassis and Differentials: Stronger chassis and heavy-duty differentials add weight. These parts help big forklift trucks stay steady.

Mounted Materials and Tires: The kind and size of tires change the weight. Rubber, plastic, or polyurethane tires all weigh different amounts. Larger tires make the forklift heavier.

Counterweights: Every forklift has a counterweight to balance heavy loads. This is a big metal block at the back. It is one of the heaviest parts of the forklift.

Attachments: Extra tools like clamps or buckets add weight. These help with special jobs but make the forklift heavier.

Type and Model: Each forklift model is built differently. Electric forklifts are lighter than ones with engines. The weight changes with the type and model.

Load Capacity: Forklifts that lift more need to be heavier. The more they can lift, the heavier they are.

Fuel Type: Electric forklifts use batteries, which are lighter than engines. Forklifts with diesel, propane, or gasoline engines are heavier.

Note: The forklift weight can change if you add or take off attachments or change the tires. Always check the real weight before moving or using a forklift in a new place.

The power source is also important for how much a forklift weighs. Electric forklifts use batteries and have a simple design. These batteries are lighter than engines and fuel tanks. This makes electric forklifts lighter and good for indoor jobs. Forklifts with diesel or gasoline engines are heavier. They need bigger counterweights and stronger frames. The extra weight helps them work outside and lift heavy things. Lead acid batteries in electric forklifts can add some weight. But electric forklifts are still lighter than big forklift trucks with engines.

Forklift Weigh by Type

Different forklifts have different weights. The weight changes based on how the forklift is built and what it does. Here is a table that shows the usual weights for common forklift types:

| Forklift Type | Typical Weight Range (pounds) |

|---|---|

| Counterbalance Forklift | 8,000 - 15,000 |

| Pallet Jack | ~2,500 |

| Telehandler (including reach forklifts) | 12,000 - 50,000 |

Counterbalance forklifts are the most common kind. They have a heavy counterweight at the back. These forklifts weigh from 8,000 to 15,000 pounds. This helps them stay balanced when lifting heavy things. Pallet jacks are much lighter. They weigh about 2,500 pounds and are good for small loads in tight spaces. Telehandlers and reach trucks are bigger. They can weigh from 12,000 to 50,000 pounds. These forklifts lift big loads and reach high places in warehouses or on building sites.

Large forklift trucks and heavy duty forklift models are much heavier than regular warehouse forklifts. Big forklift machines used in ports or heavy industry can weigh up to 140,000 pounds. These need extra weight to stay steady when lifting steel beams or shipping containers.

The weight of each forklift type depends on its job. Small electric forklifts are light and easy to move inside. Standard counterbalance forklifts have a medium weight for warehouse work. Heavy duty forklift trucks and big forklift models are the heaviest for outdoor and tough jobs.

Tip: Always check the forklift weight for your model before using it. The weight affects safety, floor strength, and how you move the forklift.

Forklift Weight vs. Capacity

Forklift Weight Capacity

Some people mix up forklift weight and forklift weight capacity. Forklift weight is how much the forklift itself weighs. Forklift weight capacity is the most weight it can lift and carry safely. This includes the load, the driver, and any extra tools. The maker decides the forklift weight capacity by looking at its design, size, and balance. They test each forklift model in perfect conditions with a 24-inch load center. You can find the rated capacity on the forklift’s data plate. Operators should always look at this plate before lifting anything.

Note: Forklift weight stays the same, but forklift weight capacity can change if you add tools or move the load.

The forklift’s own weight helps keep it steady. The design uses counterweights and strong frames to hold heavy loads. If the load is too heavy or not balanced, the forklift might tip over. Operators need to keep the load low and in the middle to stay safe.

The forklift’s weight and design help keep balance.

Good weight spread keeps the center of gravity safe.

If the load is too heavy or uneven, the forklift can tip.

Counterweights and stabilizers help with heavy or uneven loads.

Operators must know the forklift’s max lifting capacity and keep loads balanced.

How Much Can a Forklift Lift

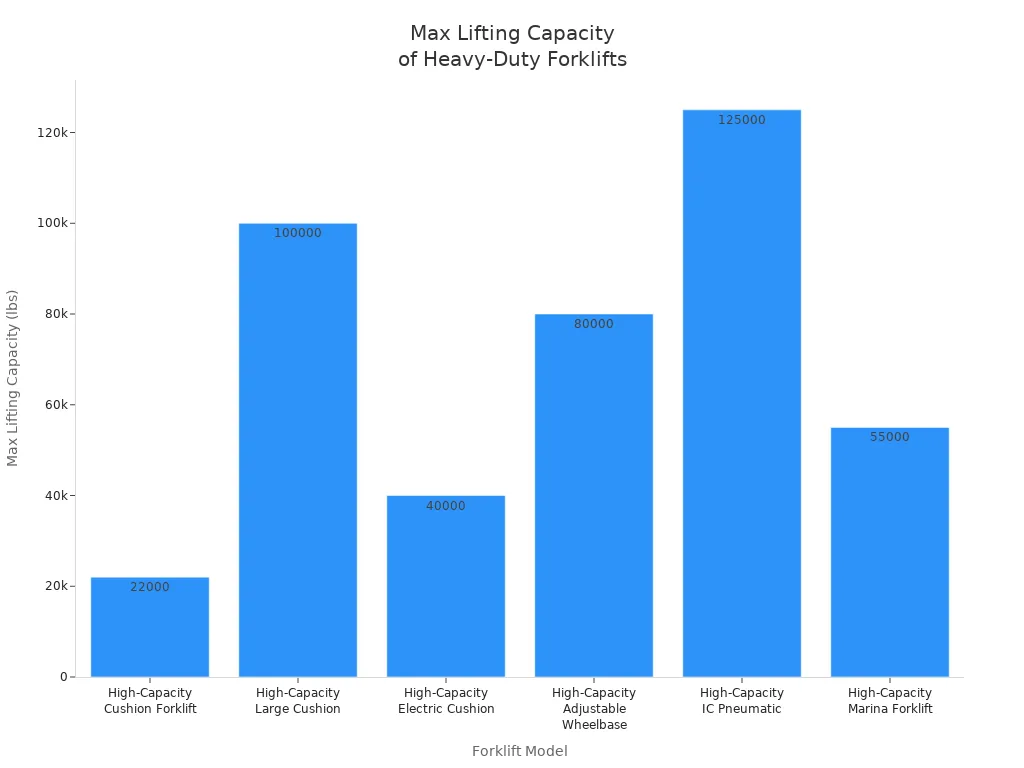

How much a forklift can lift depends on its model and rated capacity. Most warehouse forklifts lift between 3,000 and 5,000 pounds. Heavy duty forklift models and big forklift trucks can lift much more, sometimes up to 100,000 pounds. The rated capacity is always on the forklift’s data plate. This number is based on a standard load center, usually 24 inches from the fork face.

| Forklift Class | Typical Weight Capacity (lbs) | Typical Use Case |

|---|---|---|

| Class I (Electric Walkie Pallet Jack) | 4,000 - 5,000 | Retail, warehouses, docks |

| Class IV (Internal Combustion, Cushion Tires) | 50,000 - 100,000 | Indoor warehouses, loading docks, railways |

| Class V (Internal Combustion, Pneumatic Tires) | 50,000 - 100,000 | Outdoor applications like lumber yards |

Heavy duty forklift models used in shipping and building can lift up to 125,000 pounds. These big forklift machines need strong counterweights and special safety features. Lifting too much weight is dangerous and can cause accidents.

Operators should always check the data plate and never lift more than the rated capacity. The real lifting power can change with extra tools, load size, and how high you need to lift. Safe use means knowing both the forklift weight and the forklift weight capacity.

Finding Forklift Weight

Data Plate and Manual

Operators can find out how much a forklift weighs by looking at the data plate. This plate is attached to the forklift. It gives the most trusted weight information. The plate lists the forklift’s weight, lifting limit, model, and serial number. For electric forklifts, the plate shows the weight with and without the battery. It also tells the smallest and biggest battery weights. These facts help operators know the forklift’s weight in different cases.

The data plate is very important for safety. It helps stop overloading and tipping, especially with big forklift trucks or heavy duty forklift models.

If you add new tools or make changes, the maker updates the data plate. Operators should always look at the plate before using or moving a forklift, especially with large forklift machines. The operator’s manual also has important details and charts. It lists the forklift’s weight, lifting limit, and other key numbers. The manual gives facts from the maker, which are better than guessing. Operators can use the manual to check safe lifting limits and learn the weight for their forklift model.

Estimating Forklift Weight

Sometimes, the data plate or manual is missing. In these times, operators must guess the forklift’s weight using other ways:

Weigh the forklift on a big scale or ramp truck. This way gives the best answer.

Look at the maker’s spec sheets for total and net weight. These sheets often show the weight for big forklift models and heavy duty forklift trucks.

Guess by looking at the forklift’s size, frame, tires, and counterweights. Bigger frames and tires usually mean a heavier forklift.

Measure the weight of empty and loaded forks, counterweights, and any cargo to get a close guess.

Operators should use these ways to make smart choices about floor safety and moving forklifts. Knowing the forklift’s weight helps stop accidents and damage, especially with big forklift trucks or heavy duty forklift equipment. Always try to get the best number you can before moving or using any forklift.

Why Forklift Weight Matters

Safety and Stability

Forklift weight is very important for safety at work. Operators need to know how much a forklift weighs to stop accidents. If a forklift lifts too much or the load is not balanced, it can tip over. Tip-overs are a main reason for forklift accidents, especially with large forklift trucks and heavy duty forklift models.

If the weight is not spread out right or the load is too big, the forklift can fall over.

Lifting more than the rated capacity moves the center of gravity and makes rollovers more likely.

Driving too fast or not following weight rules puts people in danger.

Using load monitors and checking forklifts often helps stop overloading and keeps things safe.

A warehouse in Texas had a bad accident when a big forklift tipped over with a huge load. This showed why it is important to follow load limits and check forklift weight before using it. Good training and strict rules help lower these dangers. Operators should keep loads low and in the middle to stay steady.

Tip: Always look at the forklift’s data plate for weight and capacity before lifting or moving anything.

Transportation and Operations

Knowing the forklift’s weight is needed for safe moving and daily work. When moving a forklift, operators must pick a truck that can hold the forklift’s weight. If you guess too low, the truck or trailer can get too heavy and cause accidents. If you guess too high, you waste money and time.

The truck or trailer must be strong enough for the forklift’s weight to stop damage and keep everyone safe.

Chains or straps should be used to hold the forklift in place during travel.

Operators need to check if the trailer’s landing gear and wheels can hold the forklift’s weight.

Dock plates and floors must be strong enough for the forklift and its load.

Checking the forklift before use and driving slowly on ramps or trailers helps stop accidents.

Knowing the right forklift weight also helps follow the law. It lets operators obey road and bridge weight rules and plan safe trips. For big forklift or heavy duty forklift transport, knowing the weight stops damage and keeps people safe.

Note: Always use the right tools to hold large forklift trucks and heavy duty forklift models in place during transport.

Knowing how much a forklift weighs helps keep everyone safe. It also helps work go smoothly and stops accidents. Operators who know the weight can protect floors from damage. They can also pick the right forklift for each job. The data plate shows the forklift’s weight, lifting power, and load center. Big forklift trucks and heavy duty forklift models need extra care with these numbers. Always look at the data plate before using a forklift. Remember, forklift weight and lifting capacity are different things.

FAQ

What is the difference between forklift weight and forklift weight capacity?

Forklift weight is how heavy the machine is. Forklift weight capacity is the most it can lift safely. Operators must check both numbers before using any forklift.

How much does a big forklift or heavy duty forklift weigh?

A big forklift or heavy duty forklift can weigh 15,000 pounds or more. Some can weigh up to 140,000 pounds. Large forklift trucks need extra weight to stay steady when lifting heavy things.

Why does forklift weight matter for warehouse floors?

Forklift weight is important for floor safety. Heavy forklifts, like large forklift trucks, can hurt weak floors. Operators should check if the floor is strong enough before using a big forklift or heavy duty forklift.

Where can someone find the exact forklift weight?

The data plate on the forklift shows the exact weight. Operators can also look in the owner’s manual for this number. Always use these sources before moving or transporting a forklift.

Can attachments change how much a forklift weighs?

Yes, attachments make the forklift heavier. This changes the total forklift weight and can affect balance. Operators should update the data plate if they add new tools or attachments.

English

English