AUGUST 22, 2025

How to rent rough terrain forklift and what to consider

Anyone who wants to rent rough terrain forklift equipment for outdoor or building work has big choices to make. They need to look at their job site and what they need to lift before renting a forklift. Picking the right forklift for the job gives clear advantages:

Operators can move heavy things over bumpy ground.

Teams have less waiting time with easier material moving.

Safety problems go down when using machines made for rough terrain.

Renting a forklift with the right parts helps stop accidents and keeps work going well. People who rent rough terrain forklift machines often get better results when they pay attention to these things.

Key Takeaways

Pick a rental company near you. This helps you save money on delivery. You will also get help faster. - Look at the rental terms closely. Check insurance, maintenance, fees, and support. - Choose a forklift that fits your job. Make sure it can lift the weight you need. Check if it works on your ground and lifts high enough. This keeps you safe and helps you work better. - Use the right attachments for your job. Forks, buckets, or platforms can help you work faster and easier. - Make sure operators know how to use the forklift. Check the forklift every day. Always follow safety rules to stop accidents.

Rent Rough Terrain Forklift: Steps

Renting a forklift for rough terrain jobs can seem hard at first. But if you break it into small steps, it gets much easier. Here is how anyone can start and not make common mistakes.

Find Local Providers

First, look for companies near you that rent rough terrain forklift equipment. Many big cities in the U.S., like Atlanta, Dallas, Los Angeles, and Miami, have these rental companies. They offer different forklift sizes and features. You can search online, ask people you know, or check business directories. Make a list of at least three companies to compare.

Tip: Picking a local company can help you save money. Delivery and pickup fees are often $100 to $300 each trip.

Compare Rental Terms

After you find some companies, compare what each one offers. Rental terms can be very different. Always read the contract and ask questions. Here are some things to look for:

Insurance: Most companies want you to have insurance. This covers the forklift but not injuries or other damage. Some companies sell extra protection, but it may not cover everything.

Maintenance: Some companies include maintenance in the price. Others charge more, usually $200 to $500 each month. Maintenance helps keep the forklift safe and working.

Overtime Fees: If you use the forklift more than allowed, you may pay extra.

Delivery and Pickup: These fees depend on how far you are. Always ask for a price.

Rental Duration: Renting for longer can mean a better daily price. For example, an 8,000-pound forklift might cost $150–$250 per day, $600–$800 per week, or $1,800–$2,400 per month.

| Lift Capacity (lbs) | Rental Price Range (per day) | Rental Price Range (per week) | Rental Price Range (per month) |

|---|---|---|---|

| 8,000 | $150 - $250 | $600 - $800 | $1,800 - $2,400 |

Support Options: Good companies offer flexible rental times and mobile repair. Some give you replacement parts fast if something breaks.

Note: Always check the forklift before you rent it. Look for damage and make sure it matches the contract. This helps you not pay for damage you did not cause.

Schedule Delivery or Pickup

After you pick a company and agree on terms, plan how the forklift will get to your job site. Some companies deliver it. Others let you pick it up. Planning ahead helps you avoid delays and extra costs.

Here are some mistakes to avoid when planning delivery or pickup:

Not planning delivery or pickup can delay your project or cost more.

Guessing the wrong rental time can mean rush fees or paying for days you do not use.

Not asking about delivery details can cause problems when you need the forklift.

Tip: Always confirm the delivery or pickup date and time. Make sure someone is there to get the forklift and sign papers.

Renting a forklift for rough terrain jobs is easier when you follow these steps. Always check the rental time, fees, and support before you sign. This helps you avoid surprises and keeps your project on track.

Project Needs & When Renting a Forklift Makes Sense

Duration & Frequency

Every project is different. Before renting a rough terrain forklift, people should determine your needs by asking a few simple questions. How long you need it? Will the forklift be used every day or just for temporary surges in demand? If a team only needs a forklift for a short job, renting makes sense. For longer term rental, companies often get better rates and more flexibility.

Many rental providers offer daily, weekly, or monthly plans. If a project lasts several months, the cost can add up. Teams should look at their schedule and decide if renting fits their timeline. Renting works best for short-term jobs, seasonal work, or when a company does not want to own extra equipment.

Terrain & Environment

Where you will use it matters a lot. Outdoor job sites can have mud, gravel, sand, or uneven ground. Not every forklift can handle these conditions. Teams should check the terrain before choosing a machine. Rough terrain forklifts, telehandlers, and all-wheel drive forklifts work best for outdoor sites. These machines have large pneumatic tires with deep treads. They grip loose dirt and absorb bumps. Foam-filled tires resist punctures from debris. Lug tread patterns help forklifts move over mud and gravel.

Some job sites need forklifts with high ground clearance, reinforced frames, and sealed bearings. These features keep the forklift safe and working on rough terrain. Stability technologies like anti-tilt systems and hill hold assist help operators stay safe. Tire chains can boost traction in snow or slippery mud. Forklift size and maneuverability also matter. Teams should pick a forklift that fits the space and can turn easily.

Tip: Electric rough terrain forklifts run quietly and do not produce exhaust. They are better for sensitive environments and support green building goals. Diesel forklifts make more noise and face more rules in cities or protected areas.

Diesel forklifts can harm sensitive sites with noise and exhaust.

Electric forklifts help companies meet sustainability goals.

Some electric models qualify for green incentives.

Cost vs. Purchase

Renting and buying each have pros and cons. For short jobs, renting saves money and includes maintenance. For projects that last six months or more, buying may cost less in the long run. Owning a forklift means paying for fuel and repairs. Gas-powered forklifts can cost $10,000 to $15,000 a year for fuel. Maintenance ranges from $500 to $1,500 each year. Rental agreements often include maintenance, so renters do not worry about repairs.

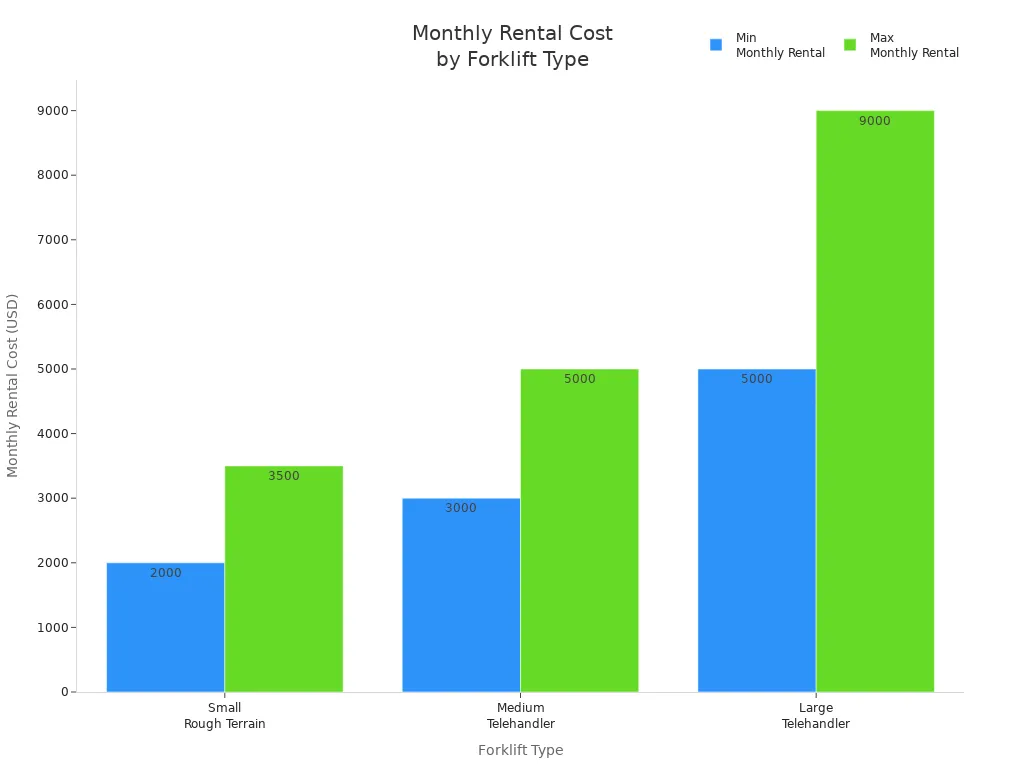

The table below shows monthly rental costs for different forklift types:

| Forklift Type | Monthly Rental Cost Range |

|---|---|

| Small Rough Terrain Forklift | $2,000 – $3,500 |

| Medium Telehandler | $3,000 – $5,000 |

| Large Telehandler | $5,000 – $9,000 |

Buying a forklift costs more upfront but can save money for long projects. Owners can get tax deductions and sell the forklift later. Renting gives flexibility and works well for short-term or changing needs. Teams should think about how much you will lift, how long the project lasts, and if they need a forklift for future jobs.

Forklift Features to Consider

Load Capacity

It is important to pick the right load capacity. Teams should check how much weight they must lift. Rough terrain forklifts come in different sizes. Small models can lift about 5,000 pounds. These are good for medium jobs on bumpy ground. Medium forklifts lift between 6,000 and 10,000 pounds. These work well for most building sites. They can move heavy things easily. Large forklifts carry up to 23,000 pounds. These are best for very heavy jobs. They move big steel beams or concrete blocks.

| Rough Terrain Forklift Class | Load Capacity Range (pounds) | Description |

|---|---|---|

| Small | ~5,000 | Medium-duty jobs on uneven terrain like inclines, rocks, or mud |

| Medium | 6,000 to 10,000 | Medium to heavy-duty jobs, includes forklifts with large pneumatic tires |

| Large | 12,000 to 23,000 | Heavy-duty applications requiring extreme load capacities |

Teams should always match the forklift’s load capacity to their needs. If the forklift is too small, work slows down. It can also be unsafe.

Lift Height

Lift height is another important thing to think about. Teams need to know how high they must lift things. Forklifts have different mast types for different jobs. Single stage upright masts are for low heights. They work well outside when there are no overhead limits. Two stage masts are good for stacking and loading. Three stage masts reach higher than most. Four stage masts are for stacking things very high. Variable reach forklifts use a telescoping boom. This lets them lift at many heights and distances.

| Mast Type | Description | Lift Height Suitability |

|---|---|---|

| Single Stage Upright | Best for lower heights or outdoor projects with no overhead clearance issues. | Suitable for low lift height requirements. |

| Two Stage | Good for stacking, double-stacking, loading/unloading trailers or box cars. | Moderate lift heights, typical construction tasks. |

| Three Stage | Provides full free lift of carriage and forks. | Suitable for above-average lift heights. |

| Four Stage | Designed for higher stacking applications. | Suitable for high lift height requirements. |

| Variable Reach | Telescoping boom for placing loads at various heights and distances. | Ideal for variable and extended lift height needs. |

Teams should pick a forklift that lifts as high as they need. This helps them move things safely and fast.

Fuel Type

Fuel type changes how and where a forklift works. Diesel forklifts are strong and work well outside. They run for a long time and refuel quickly. But they are loud and make smoke. Propane forklifts are a middle choice. They run for about eight hours and can swap tanks fast. They work inside or outside. They cost less to buy but need more care. Electric forklifts are quiet and good for the environment. They are best for indoor jobs. They do not need much care, but their batteries do not last as long. Charging takes a few hours.

| Fuel Type | Advantages | Disadvantages |

|---|---|---|

| Diesel | Durable, high torque, quick refueling, best for rough terrain | Noisy, polluting, not for indoor use, higher cost |

| Propane | Versatile, fast refueling, cleaner emissions, indoor/outdoor use | More maintenance, safety hazards, less maneuverable |

| Electric | Zero emissions, quiet, low maintenance, compact | Limited runtime, long recharge, higher upfront cost, not for rough terrain |

Teams should think about where they work and what fuel they can get. This helps them pick the best forklift.

Maneuverability

Maneuverability helps teams work in small spaces and on rough ground. Many rough terrain forklifts can turn in tight spots. Their turning radius is about 3,550 mm. Ground clearance is between 270 mm and 320 mm. This helps forklifts go over rocks and bumps. Steering angles from 43.6° to 70° help drivers turn easily. Some forklifts have special axles that move up and down. Wide tires grip dirt and mud better. Some forklifts can switch between 2WD and 4WD. This helps them go faster and climb better. Strong axles and locks help forklifts work in tough places.

Ground clearance lets forklifts move on bumpy ground.

Special axles keep loads steady over bumps.

Wide tires help forklifts grip loose dirt and mud.

Hydraulic transmission and 4WD make forklifts faster and easier to control.

Teams should look for forklifts that turn and move well. This helps them do their jobs safely and quickly.

Attachments & Accessories

Forks, Buckets, Platforms

Rough terrain forklifts can do more than just lift pallets. With the right attachments, they become very useful on job sites. Forks are the basic tool and are used for most lifting jobs. Teams use forks to move pallets, lumber, or heavy supplies. Buckets are different. A bucket lets the forklift scoop and carry loose things like dirt, sand, or gravel. This makes the forklift work like a loader for fast cleanup or moving materials.

Platforms give even more options. Workers use platforms to reach high places safely. These help with jobs like putting up lights or working on building frames. Some platforms have safety rails and floors that do not slip for extra safety.

Telescopic handlers are a common type of rough terrain forklift. They often have quick couplers and strong hydraulics. These let workers change between forks, buckets, and platforms in just a few minutes. One machine can do many jobs on a busy site.

Tip: Quick connect systems help save time and keep work going. Operators can change tools quickly and keep the project moving.

Choosing Attachments

The right attachment depends on the job you need to do. Teams should think about what they must move or lift. Here are some common choices:

Buckets: Move loose things like soil, sand, or gravel.

Clamp Attachments: Hold odd-shaped items like barrels or rolls.

Rotators: Turn loads to place or dump them better.

Booms: Reach over things or lift loads up high.

Grapples: Grab bulky or strange-shaped materials.

Platforms: Lift workers safely for jobs above the ground.

A table helps teams match each attachment to the right job:

| Attachment | Best Use | Extra Benefit |

|---|---|---|

| Forks | Pallets, lumber, supplies | Standard, easy to use |

| Buckets | Dirt, sand, gravel | Turns forklift into loader |

| Platforms | Lifting workers | Safety rails, non-slip floor |

| Booms | High or hard-to-reach loads | Acts like a mini-crane |

| Grapples | Bulky/irregular materials | Secure grip |

Picking the right attachment makes work faster and safer. Teams should always use the best tool for the job to get good results.

Safety & Compliance

Operator Training

Operator training is very important for rough terrain forklift use. In the U.S., the law says you must do a few things before driving a forklift at work. First, operators need to learn in a class, by video, or with online lessons. This training teaches how forklifts work and how to use them safely. Next, trainees must practice with a real forklift. They show they can check, drive, and turn off the forklift the right way. A trained person watches and decides if the trainee can use the forklift safely. Every three years, or after an accident, workers must take more training. Employers have to keep records of all training and tests. Many companies, like United Rentals, have classes that follow OSHA and ANSI rules. These classes mix lessons and real driving. Some are online or in other languages. This helps everyone follow the law and stay safe.

Safety Features

Modern rough terrain forklifts have many safety features to stop accidents. The table below lists some common features and how they help workers:

| Safety Feature | How It Helps Prevent Accidents |

|---|---|

| Operator Presence System (OPS) | Stops the forklift if the operator leaves the seat or unbuckles the belt. |

| Automatic Cornering Speed Reduction | Slows down the forklift during turns to stop tipping. |

| Mast Lock System | Locks the mast and forks when the operator leaves, stopping unwanted movement. |

| Rollback Control | Controls speed when backing up on slopes, preventing loss of control. |

| Forklift Camera System | Gives a better view, reducing blind spots and helping spot obstacles. |

| Reversing Radar | Warns the operator about things behind the forklift. |

| Safety Lighting System | Uses lights to alert people nearby and mark safe zones. |

Other safety tools include seat belts, alarms, horns, and bright lights. Some forklifts have blue spot lamps and big mirrors for extra safety. Checking these features often and good training help keep everyone safe.

Inspection & Maintenance

Teams should always check a rented rough terrain forklift before using it. OSHA says forklifts must be checked every day or after each shift. If something is wrong, do not use the forklift until it is fixed. Here are some daily steps:

Park on flat ground, lower the forks, and block the wheels.

Check oil, coolant, brake, and hydraulic fluid levels.

Look for leaks, cracks, or damage.

Test brakes, lights, horn, and alarms.

Check tires for wear and air.

Make sure all safety gear works.

Trained workers do weekly and monthly checks to keep forklifts working well. These checks find problems early, stop breakdowns, and help keep everyone safe.

Choosing a Rental Provider

Reputation & Reviews

Choosing the right rental company is important for your project. A good provider helps work go smoothly and keeps everyone safe. When renting a forklift, teams should look at a few things:

Safety compliance: The best companies follow OSHA rules. They check their equipment often.

Company reputation: Teams can read reviews online. They can look for awards or ask for customer stories.

Equipment quality: Good providers show maintenance records. They share inspection reports. Newer machines break down less and work better.

Customer service: Fast answers and friendly staff are important. Teams should see how quickly a company helps with questions or problems.

Tip: Companies with strong safety records and happy customers give better service.

Equipment Support

Support services help save time and lower stress during work. Most rental agreements offer helpful options:

Delivery and pick-up at your job site

Repairs if something breaks

Tire replacement for safety

Planned maintenance to keep machines working

On-site repairs to stop long delays

Help moving equipment between places

Rent-to-own choices for longer jobs

A provider with skilled workers and lots of spare parts can fix problems fast. Teams should ask about how quickly service comes and if local support is available.

Rental Policies

Rental policies protect both the renter and the company. Teams should read the agreement carefully. Ask questions if anything is not clear. Common rules include:

Only certified operators can use the forklift, as OSHA says.

Daily safety checks must happen before each use.

Insurance and liability coverage are needed. This may mean damage waivers or proof of insurance.

Some places have special rules, like limited hours or certain routes for equipment.

Forklifts often need refueling or recharging before return.

Delivery and pickup may have limits, such as height or weight restrictions.

Good communication with venue staff helps avoid problems and keeps everyone safe.

A clear rental policy helps teams avoid extra fees and delays. It also makes sure everyone follows safety rules.

Renting a forklift for rough terrain jobs is easier with a plan. Teams should pick a forklift that fits the job. They need to choose a company they trust. Safety is always important. Training helps workers use forklifts the right way. Checking the forklift every day can stop accidents. This can lower accident rates by 30%. Teams do better when they read the rental contract. They should use trained operators for every job. Paying attention to these things makes renting safer. If teams need help, they can ask rental companies before they start.

FAQ

How soon can someone get a rough terrain forklift delivered?

Most companies can bring a forklift in one or two days. Some can deliver the same day if they have one ready. It is smart to call early and check the delivery time.

Does a person need a special license to operate a rough terrain forklift?

Yes, operators need forklift certification. OSHA says you must get training and pass a test. Many rental companies can help you find local training or give you information.

What happens if the forklift breaks down during the rental?

Rental companies usually fix or swap out broken forklifts. Many send help to your job site. Always read the rental agreement to know what to do in an emergency.

Can someone rent attachments along with the forklift?

Yes, most companies rent out attachments like buckets, platforms, or booms. Ask if they are available and how much they cost when you book. Attachments can help make work easier.

Is insurance required when renting a rough terrain forklift?

Most companies want you to show proof of insurance. Some sell damage waivers for an extra fee. Insurance helps protect you if there is an accident or the forklift gets damaged.

English

English