JULY 31, 2025

Tips for maintaining and ensuring safety with lithium forklift batteries

Key Takeaways

Lithium forklift batteries have safety features built in. They have a sealed design and stable chemistry. These features help lower fire and spill risks.

Use the Battery Management System (BMS) to check battery health. The BMS helps stop problems like overheating or overcharging.

Always look at batteries every day for damage. Clean the terminals often. Make sure all connections are tight. This keeps the battery safe and working well.

Follow safe rules for charging and storing batteries. Charge batteries in cool places with good air flow. Store batteries at about 50% charge when not used.

Only trained technicians should fix batteries. Workers must follow safety training. This helps stop accidents and makes batteries last longer.

Lithium Forklift Battery Safety

Built-in Safety Features

Lithium forklift batteries have special safety parts. These parts make them safer than old lead-acid models. The battery is sealed, so you do not worry about spills or acid burns. They use lithium-iron-phosphate chemistry, which is very stable. This means they are less likely to get too hot or catch fire. The battery also balances its cells by itself when charging. This keeps each cell healthy and lowers the chance of problems. Lithium-ion batteries do not let out explosive gases. They do not need special air systems. The sealed battery stops rust and keeps dirt out. This makes your workplace safer.

Key safety features in lithium forklift batteries:

Sealed construction stops spills and acid burns.

Stable lithium-iron-phosphate chemistry lowers fire risk.

Automatic cell balancing during charging.

Less heat and no explosive gas.

Stops rust, sulfation, and dirt.

These safety parts help you avoid many dangers. They make forklift battery safety easier every day.

Battery Management System (BMS)

Battery management systems are very important for forklift battery safety. The BMS checks and controls each cell in the battery. It looks at voltage, current, temperature, and charge level. The BMS keeps the battery safe from overcharging, using too much power, and getting too hot. If it finds a problem, it can stop charging or turn off the battery to keep it safe.

What a BMS does for you:

Checks voltage, current, and temperature all the time.

Balances cells to keep them healthy and last longer.

Turns on cooling if the battery gets too hot.

Limits current to stop overheating or thermal runaway.

Can disconnect in an emergency.

Warns you about problems before they get worse.

A smart BMS can help your battery last up to 50% longer. It gives you information for regular care. This helps you stop problems before they happen. With battery management systems, you get safer use and longer-lasting lithium forklift batteries.

Certifications and Compliance

You need to use lithium forklift batteries that meet strong safety rules. These certifications show the battery can handle hard jobs and keep you safe if something goes wrong. The most important certifications and rules are:

| Certification / Standard | Description | Region / Scope |

|---|---|---|

| UN38.3 | Tests for safe transport and stops fire or explosion during shipping | International |

| UL 2580 | Covers overcharge, short-circuit, and thermal runaway protection | U.S. |

| IEC 62619 | International safety standard for industrial vehicle batteries | International |

| CE Certification | Meets EU health, safety, and environmental rules | Europe |

| GB 38031 | Safety for electric vehicle power batteries | China |

| OSHA | Needs safety training and emergency plans | U.S. |

| EPA | Controls recycling and disposal | U.S. |

| EU Battery Directive | Requires recycling and limits dangerous materials | Europe |

Always make sure your battery is approved for your forklift. Using a battery that is not approved can cancel your warranty and cause safety problems. UL 2580 certification is very important. It tests the battery for fire, drops, and other dangers. Following these rules helps you keep forklift battery safety first.

Tip: Only use manufacturer-approved lithium forklift batteries that have passed all required tests. This keeps your forklift battery safety program strong and protects your team.

Forklift Battery Maintenance

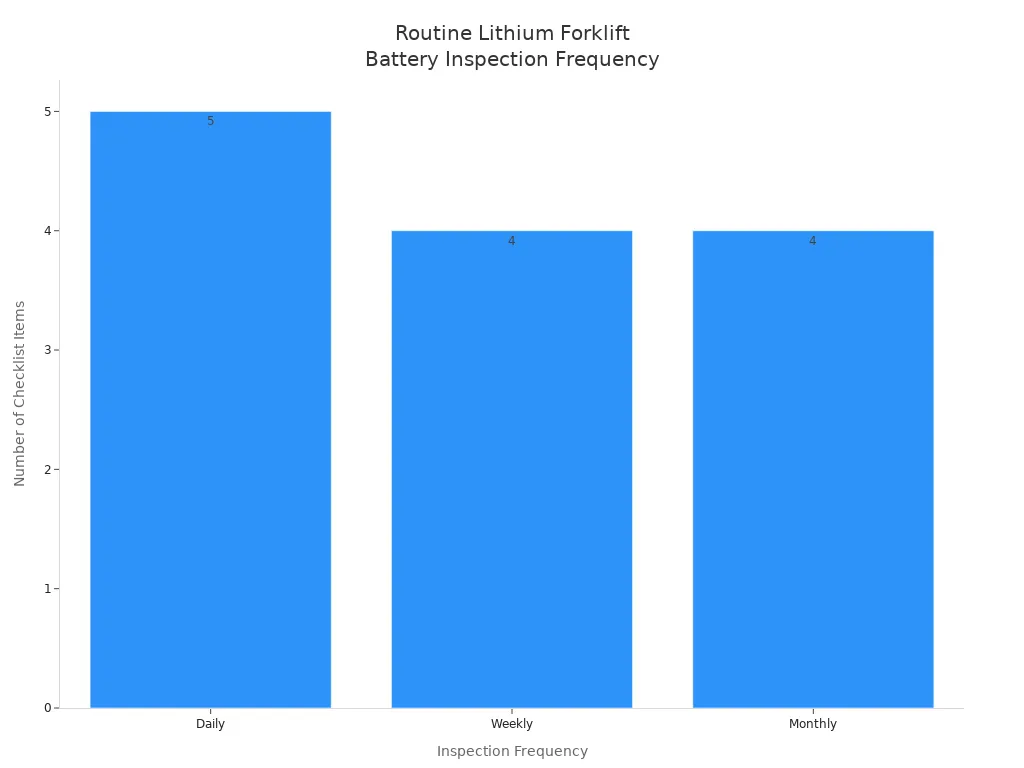

Routine Inspections

You should check your forklift battery every day and week. These checks help you find problems early. Look for cracks, leaks, or other damage. If you see a leak, act fast and use a spill plan. This keeps everyone safe. Always check the battery charge before using it. Make sure the terminals are clean and tight.

Here is a simple table to help with your checks:

| Frequency | Inspection Item | Description |

|---|---|---|

| Daily | Visual Check | Look for damage or leaks |

| Daily | Fluid Levels | Make sure fluid levels are high enough |

| Daily | Cleanliness | Wipe dirt and dust off the terminals |

| Daily | Connection Points | Tighten any loose terminals |

| Daily | Charging Status | Check how much charge the battery has |

| Weekly | Electrolyte Specific Gravity | Use a hydrometer to check fluid density |

| Weekly | Temperature Check | Watch for heat during charging |

| Weekly | Battery Case Integrity | Look for cracks or worn spots on the case |

| Weekly | Vent Caps | Make sure vent caps are tight |

| Monthly | Detailed Visual Inspection | Check wires and connectors closely |

| Monthly | Load Test | Test if the battery can hold enough power |

| Monthly | Check Charger Functionality | Make sure the charger works right and is connected |

| Monthly | Documentation Review | Keep records of all checks and repairs |

Manufacturers say to charge batteries in cool places. This stops them from getting too hot. It also keeps your battery safe. A battery management system helps you watch cell voltages and charging. Doing these steps helps your battery last longer and work better.

Cleaning and Corrosion Prevention

Keeping your battery clean is very important. Dirt and corrosion can make the battery work poorly. They can also make it die sooner. Clean the top of the battery every week. Use baking soda and water to clean the terminals. This stops acid and helps prevent corrosion. After cleaning, rinse and dry the terminals with a clean cloth. For tough corrosion, use a wire brush or cleaning tool.

Tip: Always wear gloves and safety glasses when cleaning. Even sealed batteries can have dangerous stuff on them.

After cleaning, put a thin layer of anti-corrosion coating on the terminals and clamps. This keeps them safe from rust. Put on more coating once a year or after each cleaning. Store your battery in a cool, dry place. Do not keep it in damp or hot spots like basements or kitchens. Use the original box or a battery case to keep it safe from metal.

Checking and cleaning your battery often helps you avoid big repairs. Good cleaning and storage also help the environment. This is because there is less waste and pollution. Lithium batteries last longer and need less care than lead-acid batteries. This means you replace them less and make less hazardous waste.

Checking Connections

Loose or dirty connections can make your battery lose power. They can even stop it from working. Check all connection points every day. Make sure all terminals are tight and clean. If you find a loose connection, tighten it right away. Always turn off the forklift and disconnect the battery before fixing connections. This stops sparks and keeps you safe.

If you see damaged wires or connectors, replace them quickly. Bad connections can cause overheating or fires. Keeping connections clean and tight helps your battery give steady power. It also means less downtime.

Taking care of your forklift battery saves money over time. Lithium batteries cost more at first, but they last longer and need less care. You save money on repairs, replacements, and lost work hours. Regular care can make your battery last up to 30% longer. This means fewer replacements and lower costs for your business.

Note: Well-cared-for lithium batteries help the environment. They last longer, make less waste, and use less energy than lead-acid batteries.

Charging and Storage

Safe Charging Protocols

You must always follow the manufacturer’s instructions when charging. Park your forklift in the right charging spot. Turn off the ignition and set the parking brake. Before charging, look at the battery for any damage. Wear safety glasses and gloves to stay safe. Only use chargers that fit your battery’s voltage and amp-hour rating. Never use a charger made for another battery type.

Here are steps for safe charging:

Park in a marked area and turn off the forklift.

Open the battery compartment if needed to let heat out.

Check the battery and charger cables for any damage.

Connect the charger and make sure it matches the battery.

Do not charge batteries near open flames or sparks.

Do not overcharge or undercharge. Most lithium batteries have a Battery Management System (BMS) to help with this.

Let the battery charge all the way, but do not leave it alone for too long.

Never charge a frozen or damaged battery.

Tip: You can charge lithium batteries during breaks. This is called opportunity charging and it does not hurt battery life.

Temperature and Ventilation

Temperature and airflow are very important for battery safety. Charging in places that are too hot or cold can hurt the battery. It can also make it work less well. High heat can cause the battery to get too hot or even start a fire. Cold weather makes charging slow and less effective.

Always charge and store batteries where there is good airflow.

Keep the temperature between 50°F and 80°F for best results.

Make sure the charging area has good air movement to stop heat from building up.

Do not charge batteries near heaters or in direct sunlight.

Good airflow and ventilation help stop overheating. This keeps your battery working well.

Storage Guidelines

Storing batteries in the right place keeps everyone safe. It also helps your battery last longer. Pick a cool, dry, and well-ventilated spot away from fire risks. Do not keep batteries near things that can catch fire or in wet places. For long storage, keep the battery at about 50% charge. This helps stop damage and makes the battery last longer.

| Storage Tip | Why It Matters |

|---|---|

| Store in cool, dry place | Stops overheating and moisture damage |

| Use fire-resistant cabinets | Lowers fire risk |

| Keep away from sunlight | Stops heat and battery damage |

| Maintain 50% charge | Keeps battery healthy during long storage |

| Check battery regularly | Finds problems before they get worse |

Always follow your company’s safety rules. Train workers on battery storage and what to do in emergencies.

Handling and Operation

Safe Handling Practices

You help keep your workplace safe when you handle forklift batteries. Always use safety steps to protect yourself and others. Lithium batteries are safer because they do not spill acid or make bad gases. Their strong design helps stop accidents and keeps forklifts steady.

Always read and follow the manufacturer’s instructions for putting in, charging, and storing the battery.

Do not let the battery get too hot or too cold.

Turn off chargers before you unplug the battery to stop sparks.

Check cords and battery parts for damage before you use them.

Wear gloves and safety glasses to protect yourself.

Use insulated tools when you work near batteries.

Look over your forklift before each shift and follow all safety rules at work.

Lithium batteries have Battery Management Systems (BMS) that watch temperature and voltage. These systems help stop fires and battery problems. OSHA says injuries are rare with lithium forklift batteries because they follow strict safety rules. If you use these safety steps, you help your company follow OSHA, EPA, ANSI, and MHI rules. You also lower chemical risks and make waste easier to handle.

Authorized Repairs Only

Never try to fix a lithium forklift battery unless you are trained and allowed. Only trained people know the right safety steps. If you try to fix a battery without training, you could cause overheating, fires, or explosions. Broken batteries can leak bad chemicals or catch fire if you handle them wrong.

Always use trained repair services for lithium batteries.

Never use chargers that do not fit your battery.

Do not open or mess with the battery case.

Tell your supervisor right away if you see damage or problems.

These safety steps keep you and your team safe. They also help the environment and make your battery last longer.

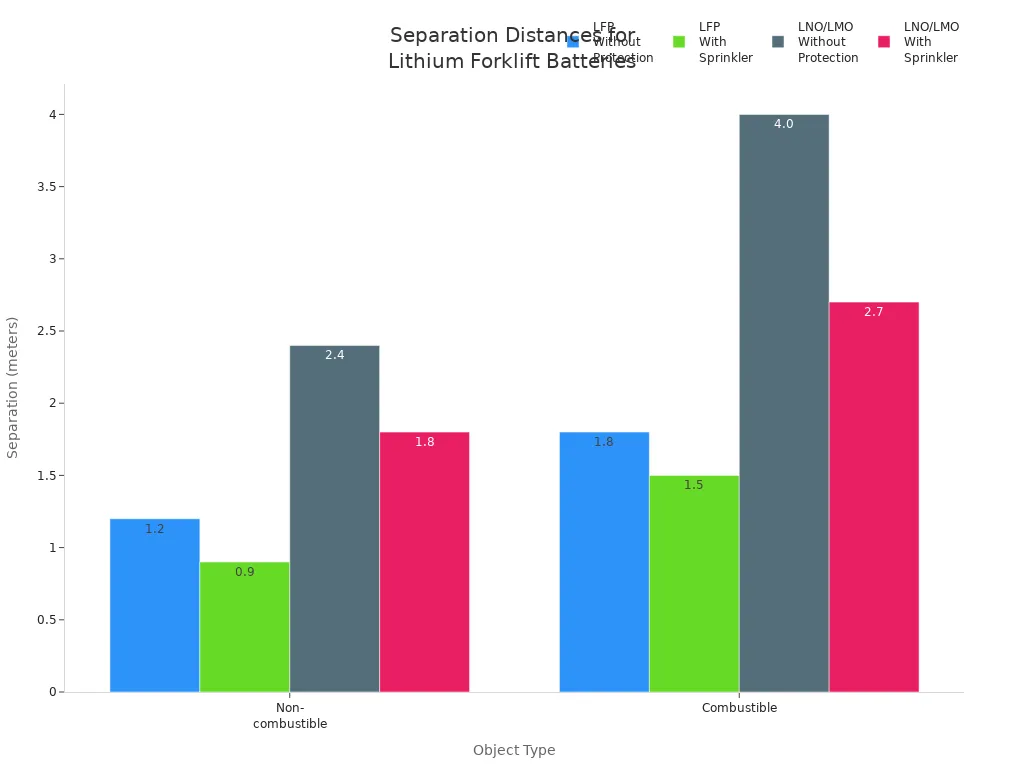

Fire Prevention Measures

Fire safety is very important with lithium forklift batteries. You must follow special rules for storage and space. The table below shows how much space to keep between batteries and other things:

| Battery Type | Fire Protection Condition | Minimum Separation from Non-Combustible Objects | Minimum Separation from Combustible Objects | Sprinkler Water Supply Requirements |

|---|---|---|---|---|

| LFP (Lithium Iron Phosphate) | Without fire protection | 1.2 m (4 ft) | 1.8 m (6 ft) | N/A |

| With sprinkler protection | 0.9 m (3 ft) | 1.5 m (5 ft) | 230 m² (2,500 ft²) demand area, minimum 90 minutes duration | |

| LNO/LMO (Lithium Nickel Oxide / Lithium Manganese Oxide) | Without fire protection | 2.4 m (8 ft) | 4.0 m (13 ft) | N/A |

| With sprinkler protection | 1.8 m (6 ft) | 2.7 m (9 ft) | Total room area coverage, water supply calculated as 45 minutes × number of adjacent racks |

NFPA 855 says you need sprinklers and must keep batteries in small groups with space between them. Store batteries at a lower charge if you will not use them for a long time. Always have emergency plans and teach workers about fire safety. Wear safety gear if there is an emergency. These steps help stop fires and keep everyone safe.

Maintaining Lithium Batteries

Monitoring Battery Health

You should check your battery’s health often. This helps your forklift stay safe. Good checks help you find problems early. You can avoid expensive repairs this way. Use a Battery Management System (BMS) to watch important things. The BMS shows charge, health, temperature, and voltage. Smart tools and telematics give you live data. They also send alerts if something is wrong.

Here are ways to watch your battery:

Use a voltmeter or multimeter to check voltage.

Watch the current when using and charging the battery.

Measure resistance to find weak cells.

Track each cell’s temperature.

Use special tools to test for cell problems.

Look at the battery and connections during regular checks.

Charge the battery the right way to stop early damage.

Teach workers how to use and charge batteries safely.

Keeping the right temperature is very important. High heat can hurt the battery and make it last less time. Always keep the battery in a safe temperature range. Watching charge and discharge cycles helps you avoid deep discharges. Deep discharges can make the battery wear out faster.

Logging and Lifecycle Management

Keeping good records is a big part of battery care. When you write down battery use and life data, you help your team find problems early. Smart BMS and live monitoring make this easy. You can spot problems, update software, and balance cells without opening the battery.

Logging gives you many good things:

You can find problems early and fix them fast.

Fewer battery failures mean less lost work time.

Safety is better with temperature sensors and alarms.

Fire systems and emergency return features help in danger.

Automatic alerts help you act quickly.

| Logging Feature | Benefit |

|---|---|

| Early fault detection | Stops breakdowns and saves money |

| Automated alarms | Makes safety and response faster |

| Lifecycle tracking | Helps the battery last longer |

| Modular design | Makes care easier and safer |

You can use these records to plan care and change batteries at the right time. This keeps forklifts working and your team safe. Taking care of lithium batteries with smart tools and good records saves money. It also helps you follow safety rules.

Electric Forklift Battery Safety Training

Employee Education

You help keep electric forklift batteries safe. Training helps everyone know what to do. You should learn how lithium batteries work. They are not the same as lead-acid batteries. The battery management system, or BMS, is important. The BMS checks voltage, temperature, and current all the time. This helps keep your battery safe.

Your training should teach you these things:

How to handle and store batteries safely, and use PPE.

The right way to lift and move batteries with the right tools.

How to check batteries every day and spot problems when charging.

How to charge batteries safely, using smart chargers that fit.

What to do if you see a battery problem or emergency.

Why you should keep learning and follow the manual.

How to help make a safe workplace by reporting problems and checking batteries often.

Safety training also teaches you to use eyewash stations and spill kits. You should know where safety signs are in battery rooms. You need to know how to use hydrogen gas detectors and keep the area aired out.

Updating Safety Protocols

You need to keep your safety rules up to date. Check your safety rules often. Change them when you get new tools or tech. OSHA says you should check operators every three years. This helps your team stay ready.

Key steps for updating rules:

Use both classroom lessons and hands-on practice.

Test what you know with written and real-life tests.

Put up clear safety signs and rules in battery areas.

Make sure fire extinguishers and smoke detectors work.

Check that spill kits and cleanup tools are ready.

Ask everyone to report dangers and give ideas to improve.

A good training plan helps stop accidents. It keeps your electric forklift battery working well. When you update your safety rules, you protect your team and your equipment.

You can make your workplace safer by using these safety tips for lithium forklift batteries:

Always do what the manufacturer says for charging, storing, and handling.

Check cords and battery parts often to see if they are damaged.

Only let trained people fix the batteries.

Keep learning and follow new safety rules.

If you take care of your battery and keep learning, you can stop accidents. This also helps your battery last longer. Start using these tips now to make your workplace safer.

FAQ

What should you do if your lithium forklift battery gets too hot?

If your battery feels hot, stop using it right away. Move the forklift to a safe area. Let the battery cool down. Check for warning lights or error codes. Tell your supervisor. Never try to cool the battery with water.

Tip: Always let a trained technician inspect an overheated battery.

How often should you inspect your lithium forklift battery?

You should check your battery every day before use. Look for damage, loose wires, or dirt. Do a deeper inspection every week. Keep a record of all checks. This helps you spot problems early and keeps your battery safe.

Can you use any charger with a lithium forklift battery?

No, you must use the charger made for your battery. Using the wrong charger can damage the battery or cause safety risks. Always check the voltage and amp-hour rating. Follow the manufacturer’s instructions for charging.

What is the best way to store a lithium forklift battery?

Store your battery in a cool, dry place. Keep it away from sunlight and things that can catch fire. Charge the battery to about 50% if you will not use it for a long time. Check the battery often during storage.

Who should repair a lithium forklift battery?

Only trained and authorized technicians should repair lithium forklift batteries. Never try to fix the battery yourself. Untrained repairs can cause fires, leaks, or other dangers. Always report any problems to your supervisor right away.

English

English