AUGUST 26, 2025

AUGUST 21, 2024

Top 15 Forklift Safety Tips Every Operator Should Know

Forklift safety is very important. Many people do not realize how risky forklifts can be. Every year, forklifts hurt many workers and sometimes cause deaths. Last year, 79 people died and over 8,000 got hurt. Most accidents happen because operators do not follow easy safety rules. Some also do not have the right training.

If you want to stop rollovers and crashes, you must learn forklift safety. Good habits and knowing what to do can keep you safe. This also helps protect others near you.

Key Takeaways

You must finish forklift training and get certified before you use one. This helps you stay safe and follow the rules.

Check your forklift every day before you use it. Look for leaks, worn tires, or broken parts.

Always wear safety gear when you drive a forklift. Use seatbelts, hard hats, and bright vests every time.

Drive slowly and follow speed limits. Do not make sudden moves. Make sure you can see well at all times.

Keep people safe by using marked walkways. Let them go first and use barriers to keep them away from traffic.

Forklift Safety Basics

Forklift safety begins with you. When you use a forklift, you have a big job. Forklifts lift heavy things, but they can hurt people if you do not follow rules. Many accidents happen when people skip steps or do not follow simple rules. You can stop these accidents by learning the basics and using them every day.

Tip: Most forklift accidents can be stopped. Good habits and training can save lives.

Operate by Manufacturer Instructions

Each forklift is not the same. Before you use a forklift, you must know how it works. Always read the manufacturer’s manual. The manual shows you how to use the controls, what safety features to check, and how much weight you can lift. If you skip this, you might miss something important that keeps you safe.

Only use a forklift if you have forklift training and certification.

Make sure your forklift has working horns, lights, and seat belts.

Check your forklift before each shift. Look for leaks, worn tires, or broken parts.

Drive safely. Follow speed limits and use spotters if you need them.

Note: The main causes of deadly forklift accidents are tip-overs, crashes, and falling loads. Knowing your forklift’s limits and following the manual can help you stay safe.

Age and Certification Requirements

You must follow rules before you can use a forklift. In the United States, you must be at least 18 years old. This rule helps make sure you are ready for the job. You also need forklift certification. This means you must take classes, practice driving, and pass written and driving tests.

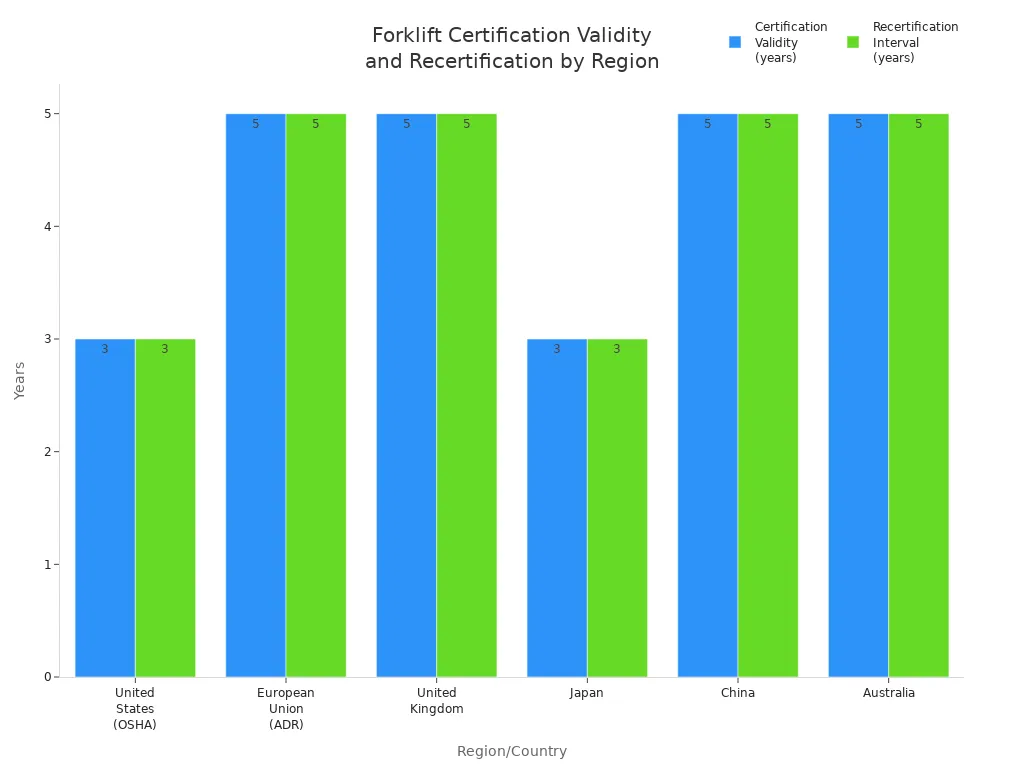

| Region/Country | Certification Validity | Training Components | Assessment Methods | Recertification Interval | Unique Requirements/Notes |

|---|---|---|---|---|---|

| United States (OSHA) | 3 years | Classroom instruction + practical training | Written test + practical driving test | Every 3 years or after incidents | Employer issues license; retraining required after accidents or near-misses |

| European Union (ADR) | 5 years | Theoretical + practical instruction | Written exam + practical driving test | Every 5 years | Some countries have specific rules; UK requires NVQ qualification |

| United Kingdom | 5 years (per EU ADR) | Competency-based training | Competency demonstration | Every 5 years | National Vocational Qualification (NVQ) required |

| Japan | 3 years | Classroom + practical instruction | Written test + practical driving test | Every 3 years | Government-regulated training |

| China | 5 years | Safe operation, maintenance, load handling | Written test + practical driving test | Every 5 years | Government-regulated training |

| Australia | 5 years | Safe operation, equipment inspection, load handling | Written test + practical driving test | Every 5 years | Regulated by Safe Work Australia |

You must renew your certification every few years. In the U.S., this is every three years. Other places have different rules, but the goal is the same. You need to keep your skills sharp and your workplace safe.

Remember: Employers can get big fines if they let untrained or underage workers use a forklift. Always make sure your training is current.

Key parts of forklift safety you should know before you use a forklift:

Finish OSHA-compliant forklift training, with class and hands-on practice.

Learn how to stay safe around people walking nearby.

Check your forklift before each use and tell someone if there is a problem.

Know how to drive safely on ramps and bumpy ground.

Learn what to do if your forklift tips over.

Check the load capacity and know how attachments change it.

Always wear your seatbelt.

Only trained people should refuel or recharge forklifts.

Use safe ways to get on and off the forklift.

If you follow these basics, you help make your workplace safer. Forklift safety is not just about rules. It is about keeping people safe.

Pre-Operation Safety Tips

Before you get behind the wheel, you need to make sure everything is safe and ready. These pre-operation safety tips help you spot problems early and keep everyone out of harm’s way. Let’s break down what you should do before you safely operate a forklift.

Pre-Use Inspection

You should always start your shift with a careful equipment inspection. This step helps you catch any issues before they turn into big problems. Here’s a simple checklist you can follow every day:

Check the horn. Make sure it works and is loud enough.

Look at all gauges. Fuel, temperature, and hour meters should show correct readings.

Inspect safety features. Test the seat belt, backup alarm, lights, mirrors, and fire extinguisher.

Walk around the forklift. Look for leaks, worn tires, or broken parts.

Check fluid levels. Look at hydraulic fluid, engine oil, and coolant.

Inspect hoses and cylinders. Watch for leaks or damage.

Examine forks and attachments. Make sure there are no cracks or bends.

Test the brakes, steering, and controls. Everything should feel smooth and responsive.

Listen for strange noises when you start the forklift.

Make sure all safety labels and nameplates are easy to read.

Tip: Always document your inspection. If you find a problem, report it right away and do not use the forklift until it is fixed.

A good equipment inspection can prevent accidents and keep your forklift running smoothly. OSHA and safety experts agree that daily checks are one of the best ways to protect yourself and others.

Wear Safety Gear

You need the right gear to stay safe on the job. Personal protective equipment (PPE) keeps you safe from many hazards in the warehouse. Here’s what you should wear every time you operate a forklift:

Hard hat: Protects your head from falling objects.

Steel-toed boots: Shields your feet from heavy loads and run-overs.

High-visibility vest: Makes you easy to see, even in busy or dark areas.

Safety glasses or goggles: Keeps dust, debris, and chemicals out of your eyes.

Gloves: Guards your hands from cuts, scrapes, and chemicals.

Hearing protection: Use earplugs or earmuffs if the warehouse is noisy.

Note: Your PPE should fit well and be in good condition. Replace anything that is worn out or damaged.

Wearing the right safety gear is one of the most important safety tips you can follow. It helps prevent injuries and shows others that you take safety seriously.

Check Surroundings

Before you move the forklift, take a moment to look around. Your work area can change quickly, and new hazards can appear at any time. Here are some things you should check:

Look for obstructions or debris on the floor. Remove anything that could cause you to slip or lose control.

Check for wet, uneven, or cluttered surfaces. These can make the forklift unstable.

Make sure your path is clear of people. Pedestrians should stay in marked walkways.

Watch for blind spots, especially near corners or racks. Use mirrors or ask a spotter for help if you cannot see.

Look up for low ceilings, pipes, or hanging objects. Know the height of your forklift and load.

Check that all warning signs and barriers are in place.

Make sure loads are secure and not stacked too high.

Be aware of ramps, docks, and other changes in floor level.

Safety Alert: Never rush this step. Taking a few extra seconds to check your surroundings can prevent serious accidents.

By following these steps, you help create a safer workplace for everyone. You also show that you are a responsible operator who cares about safety.

Safe Driving Practices

Staying safe on a forklift means you need to follow smart driving habits every time. These safety practices help you avoid accidents and keep everyone around you safe. Let’s look at the most important tips for driving a forklift safely.

Use Seatbelt

Always buckle your seatbelt before you start moving. Seatbelts save lives. Studies show that most deadly forklift accidents happen when the machine tips over. If you wear your seatbelt, you stay inside the protective frame. This keeps you from being thrown out and crushed. Many operators who skip the seatbelt get hurt or worse during a rollover. Remember, your seatbelt is your best defense.

Tip: Never try to jump out if your forklift tips. Stay inside, hold tight, and lean away from the fall.

Drive at Safe Speeds

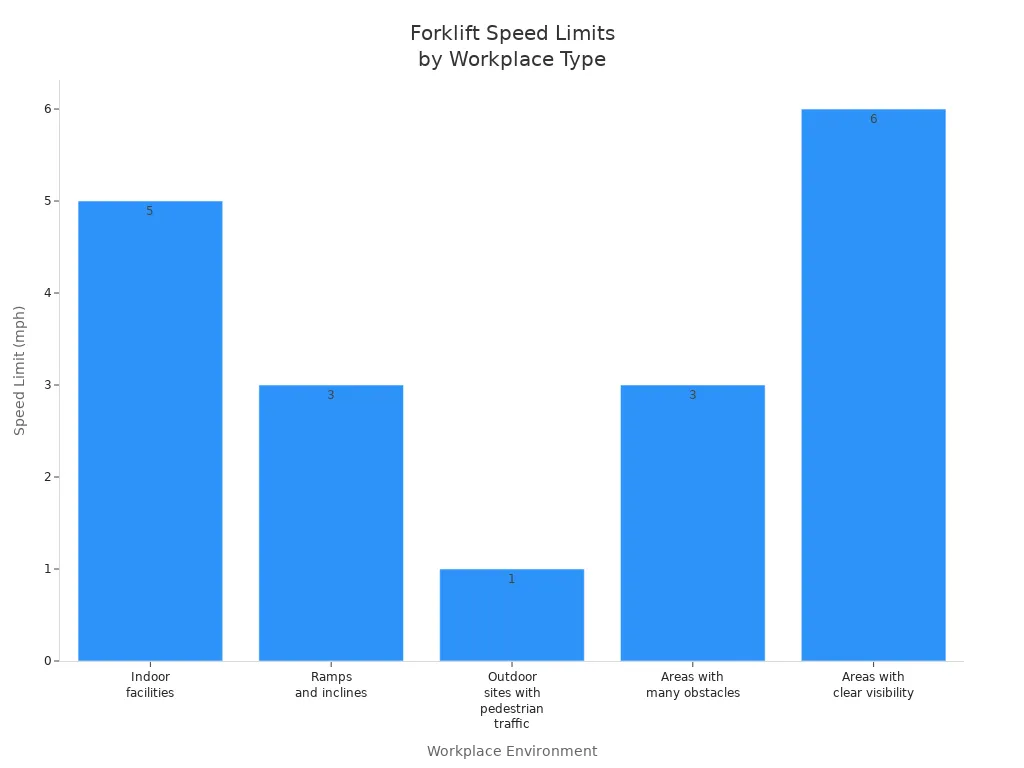

Speeding is one of the top causes of forklift accidents. You should always drive at a speed that lets you stop safely. Most indoor workplaces set a limit of 5 mph. On ramps, slow down to 3 mph. In busy outdoor areas, go even slower—sometimes just 1 mph. Your boss may post speed limit signs, so watch for them.

If you carry a heavy load or drive on a wet floor, slow down even more. Never race or rush, even if you feel behind.

Avoid Sudden Movements

Forklifts do not handle sharp turns or quick stops well. Sudden moves can make your load shift or even tip the forklift over. Many accidents happen when drivers turn too fast or slam on the brakes. Always steer smoothly and brake gently. Plan your route and avoid surprises. If you need to stop, do it slowly.

Sudden turns or stops can cause rollovers.

Quick moves can make loads fall or shift.

Always keep both hands on the wheel.

Maintain Visibility

You must see where you are going at all times. Before you move, check for blind spots. Use mirrors and ask for a spotter if you cannot see. Keep your load low so you can see ahead. If the load blocks your view, drive in reverse when it is safe. Use your horn at corners and near people. Make eye contact with pedestrians and use hand signals.

Wear high-visibility clothing.

Make sure lights and mirrors work.

Stop fully at intersections and crosswalks.

Note: Good visibility helps you spot hazards before they become problems.

Load Handling Safety Tips

Know Load Limits

You need to know your forklift’s load limits before you pick up anything. Every forklift has a rated capacity, which tells you the maximum weight it can safely lift. You can find this number on the forklift’s data plate. Most standard forklifts handle up to 4,000–8,000 pounds, while high-capacity models lift 10,000 pounds or more. The load center is usually 24 inches from the face of the forks. If you use attachments, your forklift’s capacity drops because the weight shifts forward.

Here’s a quick look at typical load limits:

| Forklift Type | Typical Load Capacity (lbs) | Notes on Capacity Determination and Attachments |

|---|---|---|

| Standard Forklifts | Up to 4,000 - 8,000 | Capacity changes with load size, distribution, and attachments |

| High-Capacity Forklifts | 10,000 lbs or more | Built for heavy loads; reinforced frames and extra safety features |

| Attachments Impact | N/A | Attachments lower capacity by shifting the load center forward |

If you go over the rated capacity, you risk tipping over and damaging your forklift. Always check the nameplate and never guess the weight of your load. This simple step helps you minimize risks and keeps everyone safe.

Proper Load Positioning

How you place your load matters just as much as how much it weighs. You should keep the load close to the forklift’s carriage and tilt it back a little for better stability. If you raise the load too high, the center of gravity moves up and forward, making your forklift unstable. Always keep loads low when you drive, especially when you turn or cross uneven ground.

Place loads evenly on both forks.

Keep the load centered to avoid tipping.

Secure the load before you lift.

Tilt the mast back slightly for extra safety.

Face the load uphill if you drive on a slope.

If you position the load wrong, you can shift the center of gravity outside the stability triangle. That’s when tip-overs happen. Operator training teaches you how to balance loads and keep the forklift steady.

Avoid Pushing or Pulling Loads

Never use your forklift to push or pull loads. Fork tips are not levers, and using them this way can damage your equipment or cause accidents. Pulling a load with the tilt cylinder is also unsafe. If you overload the forklift or add extra weight to the counterweight, you might lift the rear wheels off the ground. This can make the forklift tip over and hurt someone nearby.

Only lift loads with the forks.

Don’t use attachments for pushing or pulling unless they’re designed for it.

Always follow manufacturer guidelines.

Remember, safe load handling keeps you and your coworkers out of danger.

Pedestrian and Workplace Safety

It is very important to keep people safe near forklifts. Many forklift incidents happen when people and machines are close together. You can stop most incidents by following some easy rules.

Separate Pedestrian Traffic

Pedestrians and forklifts should not use the same paths. This helps stop forklift incidents and keeps people safe. Try these ideas at work:

Use colored lines or symbols to mark walking and driving paths. Yellow can show forklift routes, and green can show where people walk.

Make pedestrian crossings with clear floor markings and safety gates.

Put up fences or barriers to keep people away from forklift doors.

Have different doors for people, away from forklift paths.

Add LED lines or signs to show safe areas near forklifts.

Build walkways above the ground so people do not cross forklift paths.

Teach everyone, even visitors, which paths to use.

Tip: Check your workplace often for new dangers and change routes if needed.

Use Guards and Barriers

Guards and barriers help keep people and forklifts apart. They make the workplace safer for everyone. Here are some ways to use them:

Put guardrails, bollards, or gates between walkways and forklift lanes.

Use barriers that can take a hit to protect people from forklifts.

Mark aisles and walkways with bright paint or tape.

Place barricades in busy spots where people and forklifts might meet.

Use warning lights and signs to remind people about danger zones.

Barriers do more than just block forklifts. They also help remind you and others to stay alert. OSHA says there are thousands of forklift incidents every year, so barriers are very important.

Give Way to Pedestrians

Pedestrians always have the right of way. This is not just a good idea—it is the law in many places. Here is what you should do:

Slow down and use your horn when people are close.

Make eye contact before you move through a pedestrian area.

Stop and let people cross before you drive on.

Follow speed limits, especially where people walk. Three miles per hour is common.

Watch for signs and signals that show pedestrian crossings or no-go zones.

Keep aisles clear and marked so everyone knows where to walk.

Safety Alert: If you do not follow these rules, you could get fined and cause more forklift incidents. Training helps everyone remember to stay safe.

Forklift Safety Toolbox Talk

Communicate Safety Procedures

You help keep your team safe. Safety toolbox talks remind everyone about the rules. These talks use real stories to show why safety matters. Start by sharing examples of forklift accidents. Ask your team which rules get broken most. This gets people talking and helps everyone see why safety is important.

Here’s how you can lead a good safety toolbox talk:

Talk about training, inspections, safe driving, load handling, and workplace dangers.

Show pictures, diagrams, or short videos of good safety.

Go through inspection checklists together. Let operators say what to check and why.

Ask questions and listen to feedback. This clears up confusion and helps fix problems early.

Give out posters or checklists for daily use.

Hold toolbox talks often. Reward safe actions and remind everyone to report unsafe ones.

Safety toolbox talks work best when everyone joins in. Let your team share stories and ask questions. This builds trust and helps everyone learn.

Address Common Hazards

You face many dangers when you use a forklift. Talking about these risks during toolbox talks keeps everyone alert. Here are some hazards to discuss:

Unbalanced loads can tip over your forklift.

Driving too fast, especially on corners or ramps, causes rollovers.

Propane forklifts can release carbon monoxide. Make sure the area has good airflow.

Not wearing a seatbelt puts you at risk in an accident.

Uneven floors, tight spaces, and steep ramps make driving harder.

Reckless moves or stunts can hurt you and others.

Bad unloading can drop loads or break equipment.

Pedestrians near forklifts need extra care.

Leaving forklifts parked in the wrong spot can cause accidents.

Fueling and charging batteries have their own risks.

Always talk about near misses and ask your team to report them. This helps you find problems before someone gets hurt.

A safety toolbox talk lets you review these hazards and remind everyone how to stay safe. Keep talking and update your team when new risks show up.

Forklift Training and Maintenance

Comprehensive Forklift Training

You must get forklift training before using one. Good training teaches you how to stay safe. You learn how to check your forklift and handle loads. You also learn to watch for people walking nearby. Training gives you real practice with the forklift. This helps you learn how the controls work. You find out how to move the forklift safely.

A good forklift training program gives you:

Steps for checking, handling loads, and what to do in emergencies.

How to steer, lift, and balance loads.

How to spot dangers before they cause problems.

Real practice with forklifts and help from experts.

Tests on paper and driving to check your skills.

Most accidents happen when people skip training or forget rules. Studies say training can stop up to 70% of accidents. You should take more training often to keep your skills strong. OSHA says you need new training every three years. Many companies want you to do it every year or two.

| Aspect | Frequency / Requirement |

|---|---|

| OSHA Recertification Requirement | At least every 3 years |

| Recommended Refresher Training | Annually or every 1-2 years |

| Factors Influencing Frequency | Experience, task complexity, safety records, new equipment |

| Additional Employer Requirements | After accidents or new equipment introduction |

Regular Maintenance

You keep your forklift safe by checking it often. Fix problems as soon as you find them. Regular checks stop small problems from getting worse. You should look at your forklift every day before work. Check for leaks, bad tires, and strange sounds. If you see a problem, tell someone and do not use the forklift until it is fixed.

Here is how often you should do maintenance:

| Maintenance Interval | Recommended Tasks and Focus Areas |

|---|---|

| Daily | Check for leaks, tire damage, odd noises, and safety features (lights, brakes, horn) |

| Every 250 Hours | Replace engine oil, inspect hydraulic system, filters, lubricate moving parts |

| Every 500 Hours | Inspect mast and chain, drive system, replace certain filters and fluids |

| Annually or 1,000-2,000 Hours | Major service: engine, transmission, electrical systems, load testing, calibrate safety features |

Some common problems are worn tires, steering trouble, and leaks. Bad tires can make your forklift tip over. Leaks can make lifting rough. Steering problems make it hard to control the forklift. You avoid these dangers by following a schedule and changing parts when needed. Extra training reminds you to check these things.

When you get good training and do regular checks, you help keep everyone safe. This keeps your forklift working well and protects your team.

You help make your workplace safer. When you use forklift safety tips, you stop accidents. You protect yourself and others.

Training helps you learn how to stay safe. Safety signs remind you of rules.

Checking forklifts often and smart warehouse design lower risks.

Good operators work better and help companies save money.

Always pay attention, keep learning new things, and choose safety. What you do matters!

FAQ

What should you do if your forklift fails an inspection?

If your forklift fails an inspection, stop using it right away. Report the problem to your supervisor. Do not try to fix it yourself unless you have training. Wait for a qualified person to repair it.

How often do you need forklift training?

You need forklift training every three years in the U.S. Some companies want you to train more often. If you have an accident or get new equipment, you may need extra training.

Can you use a forklift to lift people?

No, you should never use a forklift to lift people unless you have a special work platform. Always follow the manufacturer’s instructions. Lifting people without the right equipment is very dangerous.

What should you do if your forklift starts to tip over?

Stay in your seat. Hold the steering wheel tight. Lean away from the direction of the tip. Never jump out. Your seatbelt and the forklift’s frame protect you best.

English

English