AUGUST 22, 2025

Why rough terrain forklifts are essential for outdoor material handling

Rough terrain forklifts are very important for moving things outside. These forklifts carry heavy items over rough ground like gravel, mud, and sand. Their big tires and strong frames help them work in tough outdoor places. Many jobs need rough terrain forklifts every day:

Construction workers use forklifts to lift things to roofs and high floors.

Farmers use rough terrain forklifts to move crops and supplies.

Military teams use them to carry equipment over bumpy ground.

Workers at oil refineries and road work sites move big loads outside.

Rough terrain forklifts can handle bad weather and uneven ground, so they are needed in hard places.

Key Takeaways

Rough terrain forklifts have large tires and strong frames. These help them move safely on bumpy, muddy, or rocky ground. Advanced suspension and all-terrain tires keep these forklifts steady. This makes the ride smoother and safer. It also helps drivers feel less tired. These forklifts are made strong with extra-tough frames. They have parts that can handle bad weather. This helps them last longer outside. They can lift very heavy things. This makes them great for building, farming, and roadwork on rough ground. Doing regular check-ups and good training keeps them working well. This also saves money on repairs over time.

Rough Terrain Forklifts: Traction and Stability

Rough terrain forklifts are great at moving heavy things outside. They work well on gravel, mud, sand, and bumpy ground. Their design helps them grip the ground and stay steady. This is important for safe and easy outdoor work.

All-Terrain Tires

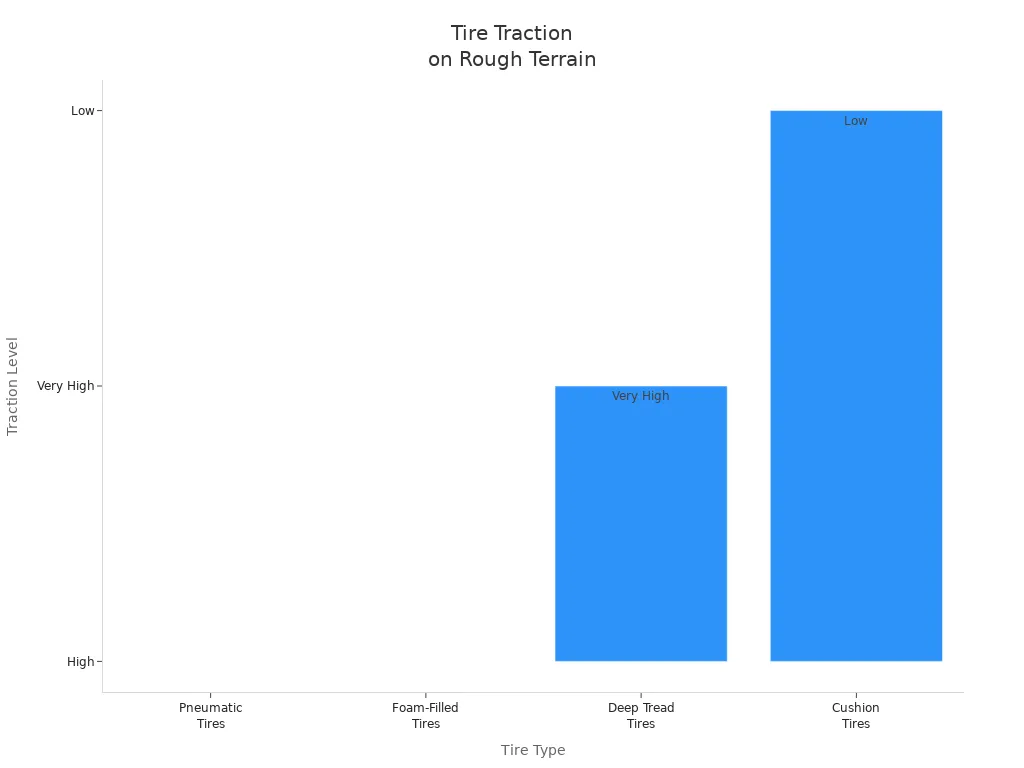

All-terrain tires help rough terrain forklifts do their job. There are different types of these tires. Each type has its own way of helping on rough ground. The table below shows how each tire type helps with grip and balance:

| Tire Type | Traction Feature | Function on Rough Terrain |

|---|---|---|

| Pneumatic Tires | Air-filled with deep treads | Give good grip and absorb bumps on loose ground like gravel and dirt |

| Foam-Filled Tires | Puncture-resistant with pneumatic-like performance | Last longer in places with sharp things, keep grip without going flat |

| Deep Tread Tires | Aggressive, deep lugs (e.g., chevron or block) | Dig into mud or rocks so the forklift does not slip |

| Cushion Tires | Smooth, minimal tread | Not good for rough ground because they do not grip well and sit too low |

Big pneumatic tires with deep treads help forklifts grip loose or wet ground. These tires also soak up bumps from rocks, which protects the forklift and what it carries. Foam-filled tires do not pop easily, so they are good where there are sharp objects. Deep tread tires, like chevron or block types, dig into mud or sand to stop slipping. Cushion tires do not have enough grip or height for rough ground.

Some important things about all-terrain tires are:

Big pneumatic tires give great grip and a soft ride.

Deep treads hold onto gravel, mud, and other tough ground.

Strong rubber keeps tires from popping or wearing out fast.

Good shock absorption makes bumps easier and helps the driver feel less tired.

All these things help forklifts stay balanced and in control on rough ground.

Advanced Suspension

Advanced suspension systems make rough terrain forklifts even steadier. These systems use hydraulic parts and special axles to keep the forklift level on bumpy or sloped ground.

Hydraulic systems change the pressure at each wheel to spread out weight and keep the forklift steady. This helps stop it from tipping, even on hills.

Wheels with their own suspension soak up bumps from holes and rocks, so loads do not move suddenly.

Adjustable hydraulic shocks cut down on shaking, which protects the forklift and the driver.

Multi-link axles help take in bumps, making the ride smoother and safer.

Anti-rollover parts and strong brakes stop skidding or losing control.

Having more space under the forklift also helps a lot. Rough terrain forklifts usually have 12 inches or more of space under them. Regular forklifts only have about 4 inches. This extra space lets them go over things and not get stuck. Four-wheel drive sends power to all wheels, so the forklift keeps moving on slippery or bumpy ground. Axles that bend help all tires touch the ground, which gives better grip and balance.

Tip: Drivers feel much safer and more comfortable with advanced suspension and all-terrain tires. These features help them get less tired and make it easier to move heavy things on rough ground.

Rough terrain forklifts use all-terrain tires, strong grip, and advanced suspension to stay steady. These features help forklifts work safely and well in tough outdoor places.

Durability in Rough Terrain

Rough terrain forklifts face hard outdoor conditions every day. Their tough build and smart design help them last longer than regular forklifts. These machines keep working even when the ground is rough or the weather is bad.

Reinforced Frames

Manufacturers make rough terrain forklifts with strong frames. These frames do not bend or crack easily. They carry heavy loads over rocks and uneven ground. The mast and frame are built to be extra strong. This helps the forklift take hits without breaking.

Sealed bearings keep dirt, mud, and water out of moving parts. This helps the forklift last longer and wear less.

Heavy-duty hydraulic systems help the forklift work well for many hours outside.

Weather-resistant cabs and controls protect important parts from rain, dust, and heat.

The table below shows how these features help forklifts last:

| Feature | Benefit |

|---|---|

| Reinforced frame | Stops bending and cracking |

| Sealed bearings | Blocks dirt and moisture |

| Heavy-duty hydraulics | Handles tough jobs for longer |

| Weather-resistant cab | Protects controls from harsh weather |

These design choices help rough terrain forklifts work outside for many years. Regular forklifts are made for smooth floors. They do not last as long outside.

Weather Resistance

Rough terrain forklifts are built to handle bad weather. They work in rain, snow, heat, and cold. Water-resistant parts keep rain and snow from hurting the forklift. Dust-resistant seals help forklifts run in dry, dirty places.

All-season tires help forklifts grip wet or icy ground.

Four-wheel drive helps forklifts move in mud, snow, or rain.

Waterproof parts protect engines and controls during storms.

Climate-controlled cabins keep drivers safe and comfortable in any weather.

High-torque engines give power, even when it is very hot or cold.

Operators should check the weather before working outside. They should get ready for heat, cold, or storms. Regular checks, like looking at tires and fluids, help forklifts stay strong. Good training keeps workers safe when using forklifts outdoors.

Rough terrain forklifts often last between 10,000 and 20,000 hours. Their strong frames, sealed parts, and special tires help them last longer. These features help them work where regular forklifts would break down.

Note: Taking care of a forklift can help it last up to 30% longer. Outdoor forklifts need regular care to stay strong.

Forklifts for Heavy Loads

High Load Capacity

Rough terrain forklifts can lift very heavy things outside. These machines help workers move big loads on bumpy ground. Many straight-mast rough terrain forklifts lift 5,000 to 20,000 pounds. Most rental forklifts lift between 6,000 and 10,000 pounds. This is enough for many outdoor jobs. Some telehandlers can lift even more weight. For example, the MYZG 7T off-road forklift lifts up to 70,000 pounds. The Manitou MHT 12330 telehandler lifts as much as 72,753 pounds. These numbers show how strong modern forklifts are in tough places.

Tip: Workers should always look at the forklift’s load chart first. This keeps everyone safe and stops damage to the forklift.

High load capacity means forklifts carry building materials or big pallets easily. They also move heavy farm supplies without problems. This makes them great for construction, farms, and roadwork.

Powerful Engines

A strong engine helps rough terrain forklifts move heavy loads outside. These engines make high torque for climbing hills or driving through mud. Diesel forklift trucks have engines that give smooth power and quick starts. They work well even with big loads. Internal combustion forklifts have more power than electric ones. This helps them work better outside on uneven ground.

High-torque engines help forklifts move on steep or bumpy ground.

Big tires and strong suspensions help keep the forklift steady.

A strong engine lets the forklift work longer without stopping.

Rough terrain forklifts use strong engines and high load capacity for hard jobs. These features help workers finish tasks faster and stay safe.

Outdoor Applications

Construction Sites

Construction sites are hard places to move things. The ground is often bumpy, muddy, or covered in gravel. Rough terrain forklifts help workers with these problems. Their big tires have deep treads that grip the ground well. Strong suspension lets drivers go over rocks and bumps without breaking the forklift. Powerful engines give enough strength to lift heavy things and go up hills. Four-wheel drive helps the forklift move and turn on rough ground.

Workers use rough terrain forklifts for many jobs:

They unload bricks, cement, and sandbags from trucks onto muddy or uneven ground.

They move formwork, steel bars, and scaffolding up hills or to higher spots.

They clear trash and load sand using special tools like buckets and grippers.

These forklifts have strong frames and smart stability systems. Wide wheelbases and low centers of gravity help stop them from tipping over. Comfortable cabins and easy controls help drivers feel less tired and work better. OSHA training teaches drivers how to use forklifts safely and check them every day. Trained drivers have fewer accidents and get more work done on construction sites.

Tip: Good training and daily checks help keep forklifts safe and working well outside.

Farming and Roadwork

Rough terrain forklifts are very important for farming and roadwork. Farmers use them to move and stack hay bales, load animal feed, and carry fertilizer and seeds across wet or bumpy fields. Forklifts also move crops from the field to storage. In roadwork, workers use forklifts to move concrete blocks, bricks, and other heavy things over rough ground.

Drivers often use special tools to pick up odd-shaped things like pipes and logs. These features make rough terrain forklifts useful for many outdoor jobs. They can work in mud, water, or on hills, which regular machines cannot do. Their strong engines and tough frames help them work well in hard places.

| Application Area | Common Tasks |

|---|---|

| Farming | Moving hay bales, loading feed, transporting crops |

| Roadwork | Carrying concrete blocks, bricks, clearing debris |

Rough terrain forklifts help many industries by making outdoor work safer and easier.

Versatility and Value

Adaptability

Rough terrain forklifts can do many jobs outside. They work well in different places and for many tasks. Operators can change attachments like buckets, pallet forks, or work platforms. This helps them move different things or do new jobs. These machines use special tires, like pneumatic and foam-filled types. These tires grip bumpy ground and help with shocks from rocks. High ground clearance lets forklifts drive over rocks and trash without getting stuck.

Many forklifts have four-wheel or all-wheel drive. This gives better control and power on soft or rough ground. Strong frames and sealed bearings keep dirt and water out of moving parts. This helps the forklift last longer. Good hydraulic systems make lifting smooth, even on rough ground. Comfortable cabs help drivers feel good during long work hours. Companies can pick diesel or electric power to fit their needs and help the environment.

Operators use these forklifts in construction, farming, and roadwork. Forklifts can lift heavy things, clear trash, drill holes, or even move snow with the right tools. This makes it cheaper for companies because one machine can do many jobs.

Maintenance Savings

Rough terrain forklifts help save money on repairs over time. Diesel forklifts need oil changes and new filters often, which costs money. Fixing the transmission can cost a lot after some years. Lithium-electric forklifts do not need oil changes or big transmission repairs. They use less fuel and keep their value better.

Some common problems are leaks, brake issues, and electrical faults. Hot, dirty, or wet weather can make these problems worse. Checking hoses, fittings, and wires often helps stop breakdowns. Sealed bearings and good hydraulic parts keep out dirt and dust. This means less time fixing the forklift and lower repair bills.

| Maintenance Task | Diesel Forklift Cost | Lithium-Electric Cost |

|---|---|---|

| Oil Change (Quarterly) | $150-$300 | $0 |

| Filter Replacement | $400-$600/year | $0 |

| Transmission Overhaul | $3,000-$5,000 | $0 |

| Annual Fuel Cost | $4,500-$7,000 | $500-$1,000 |

Buying rough terrain forklifts with strong frames and engines means fewer repairs and longer use. Companies spend less on fuel, repairs, and lost work time. This makes these forklifts a smart choice for working outside.

Rough terrain forklifts help with outdoor jobs because they are tough. Their strong frames keep them safe on rough ground. Advanced tires help them grip and move over bumps. Powerful engines let them carry heavy things outside. These machines have safety features like seatbelts and rollover bars. Stability control helps stop them from tipping over. Operators can move big loads fast and safely, even on uneven ground. Experts say these forklifts last a long time and work well in hard places. Companies save money over time by using rough terrain forklifts for outdoor work.

FAQ

What makes a rough terrain forklift different from a standard forklift?

Rough terrain forklifts have large tires, strong frames, and high ground clearance. These features help them move safely on uneven or soft ground. Standard forklifts work best on smooth, flat surfaces.

Can rough terrain forklifts work in rain or snow?

Yes. Manufacturers build rough terrain forklifts with weather-resistant parts. These machines keep working in rain, snow, heat, or cold. Operators should still check the forklift before use in bad weather.

How much weight can a rough terrain forklift lift?

Most rough terrain forklifts lift between 5,000 and 20,000 pounds. Some heavy-duty models can lift even more. Operators should always check the load chart for the exact weight limit.

What industries use rough terrain forklifts the most?

Construction, farming, and roadwork crews use rough terrain forklifts every day. These machines help move heavy loads, supplies, and equipment across outdoor job sites.

Are rough terrain forklifts hard to maintain?

No. Many models use sealed bearings and strong parts to keep out dirt and water. Regular checks and simple care help these forklifts last longer and work better.

English

English