AUGUST 28, 2025

3 ways to help create a sustainable warehouse

Key Takeaways

Use energy-saving lights and smart HVAC systems to cut costs and use less energy.

Start recycling programs and teach workers to help lower waste and care for the environment.

Use automation and AI to make work easier, which helps save energy and supports sustainability.

Optimize Energy Use

You can help your warehouse be more sustainable by managing energy better. This means using less energy and making smart choices every day. Saving energy helps the environment and saves you money too. There are many ways to make your warehouse use energy better.

Efficient Lighting

Changing to energy-efficient lighting is a great way to help the planet. LED lighting uses much less energy than old bulbs. LEDs also last longer than regular lights. You can save a lot of money on energy bills with LEDs. The US Department of Energy says LED lights can save billions of dollars over time. LEDs give brighter light and do not waste energy as heat. Smart lighting systems let you control lights from your phone or computer. These systems turn off lights when no one is there. Upgrading to LEDs often pays for itself in less than three years. This is important for a sustainable business.

Benefits of LED lighting:

Uses less energy than traditional lights

Lasts longer and needs less maintenance

Improves worker safety and comfort

Smart Climate Control

Smart climate control systems help you manage heating and cooling. These systems use sensors and automation to keep temperatures steady. Using high-efficiency HVAC systems lowers your energy use. Smart controls turn off heating or cooling when not needed. You can also use heat pumps with green refrigerants. These steps help the environment and support sustainable warehousing. Smart climate control is a big part of energy management and energy efficiency.

Tips for smart climate control:

Use intelligent sensors to track temperature

Set up remote monitoring for your HVAC system

Design your system for future climate changes

Equipment Monitoring

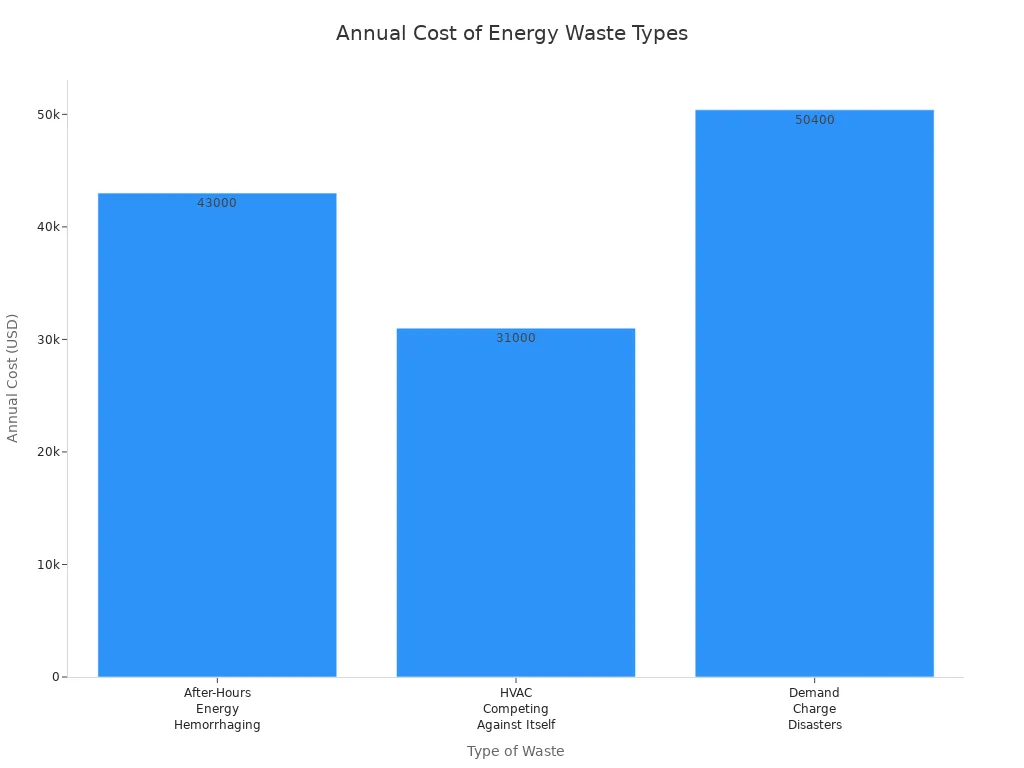

Watching your equipment helps you find where energy is wasted. Many warehouses lose money when machines run after hours. Sometimes heating and cooling systems work against each other. Tracking your equipment helps you stop these problems and save money. The table below shows how much energy waste can cost each year:

| Type of Waste | Annual Cost | Description |

|---|---|---|

| After-Hours Energy Hemorrhaging | $43,000 | Equipment running during non-operational hours due to basic timer controls. |

| HVAC Competing Against Itself | $31,000 | Heating and cooling systems operating simultaneously due to temperature fluctuations. |

| Demand Charge Disasters | $50,400 | Electrical demand spikes caused by poor load management during peak rate periods. |

| Total Operational Waste | $191,400 | Total annual waste from inefficiencies identified by monitoring systems. |

| Net Savings | $150,000-$200,000 | Facilities typically recover their investment within 45-60 days and achieve significant savings. |

You can use technology to watch energy use and fix problems fast. This helps make your warehouse more sustainable and lowers your impact on the environment. Good energy management leads to green warehousing and supports renewable energy use.

Recycling & Waste Reduction

Cutting down on waste helps your warehouse stay green. You can set up recycling stations. Train your team to recycle. Reuse pallets when you can. These actions help green warehousing and lower harm to the planet.

Recycling Stations

Put recycling stations in important spots in your warehouse. These stations help everyone sort and recycle things like cardboard, plastic, and metal. Recycling more means less trash goes to landfills. It also helps with zero-waste goals. Recycling stations let you keep track of waste and resources. This is good for green projects.

Tip: Put clear labels on each bin. This helps your team know what goes in each bin. It makes recycling easier and helps you reach your green goals.

Staff Training

Teaching your team is important for a green warehouse. Show everyone how to sort waste. Explain why recycling matters. Hold training often to keep everyone updated. Pick waste reduction leaders to help others and check progress. Teaching your team helps them join green efforts and try new ideas. Staff training cuts waste and helps your warehouse be better for the planet.

Benefits of staff training:

Everyone learns how to recycle.

Workers see how their choices help green warehousing.

You create a team that cares about the environment.

Reuse Pallets

Using pallets again is a smart way to help your warehouse. Reusing pallets lowers greenhouse gases and keeps trash out of landfills. It also saves water and energy. The table below shows how reusing pallets helps the earth:

| Environmental Benefit | Description |

|---|---|

| Reduces Deforestation | Selling used pallets means less new wood is needed. This helps forests. |

| Lowers Greenhouse Gas Emissions | Using pallets again saves energy and cuts fossil fuel use. |

| Reduces Landfill Waste | Many pallets do not end up in landfills each year. |

| Conserves Water and Energy | Making fewer new pallets uses less water and energy. |

You can work with local recycling companies to reuse pallets. These companies buy old pallets and sell fixed ones. This can lower electric bills and save money. Working with recyclers helps you reach net zero carbon goals. It also helps you use solar power in your warehouse. Smart tech like LED lights can help your green efforts and support renewable energy.

Eco-Friendly Materials

Efficient Packaging

You can help the planet by using better packaging. Many companies pick recycled cardboard and plastics. Some use biodegradable packaging that breaks down on its own. This kind of packaging makes less trash. Using less material in packaging saves money and cuts waste. Reusable packaging lets you send back containers to use again. This creates a loop where nothing is wasted. New ideas include mono-materials, compostable packaging, smart labels, and lighter designs. These choices help warehouses make less trash and recycle more. The table below shows how these packaging ideas help:

| Innovation Type | Benefits | Companies Involved |

|---|---|---|

| Mono-materials | Makes less waste and is easier to recycle | Kraft Heinz, Notpla |

| Compostables | Breaks down and keeps trash out of landfills | Various startups |

| Smart labels | Helps track items and makes work faster | Tech companies |

| Lightweight designs | Cuts shipping costs and saves fuel | Multiple manufacturers |

Green Building

You can make your warehouse better by using green building materials. Building this way is good for the earth. Energy-saving tools help you use less power. Better air systems move heat around and keep the warehouse comfy. This means you do not need as much heat. Using recycled materials in your warehouse is good for the planet. These steps help your warehouse be green and support clean energy.

Green building helps the earth.

Energy-saving tools use less power.

Better air systems spread heat well.

Build Upward

Building up helps you use your space better. Vertical storage lets you keep more things in less room. This means you use less land and make less pollution. Smart tech like LED lights and robots saves energy. Good inventory systems mean less waste and fewer broken items. Building up helps your warehouse be green.

Tip: Use tall shelves to save space and help the planet.

You can help your warehouse by using green habits each day. Keep track of what you do and find new ways to help the earth. When you work on being green, you get:

Cost savings

Better brand image

Happier workers

Customers who are more satisfied

A stronger supply chain

FAQ

What are the main benefits of sustainable warehouse logistics?

You can save money and help the environment. Worker safety gets better too. Sustainable warehouse logistics help you reach green goals. They also bring in customers who like eco-friendly choices.

Tip: Sustainable warehouse logistics help your warehouse work better and grow over time.

How can you start using sustainable practices in your warehouse?

Set up recycling stations in your warehouse. Try to reuse pallets when you can. Change to green packaging for your products. These steps help you build a sustainable warehouse. They also support sustainable warehouse logistics.

Why should you focus on sustainable warehouse logistics?

| Sustainable warehousing helps you: |

|---|

| Use less energy |

| Spend less money |

| Make your brand stronger |

English

English