AUGUST 28, 2025

Calculating Forklift Aisle Width Minimums

You need to know the right forklift aisle width for safe warehouse work. Wide aisles usually measure 12 to 13 feet, while narrow aisles range from 8 to 10 feet. Very narrow aisles can be as small as 6 feet.

| Aisle Type | Width Range |

|---|---|

| Wide Aisles | 12 to 13 feet |

| Narrow Aisles | 8 to 10 feet |

| Very Narrow Aisles | Around 6 feet |

Key Takeaways

Learn the usual aisle widths. Wide aisles are 12 to 13 feet. Narrow aisles are 8 to 10 feet. Very narrow aisles can be as small as 6 feet. - Use this formula for aisle width: Minimum Aisle Width = Right Angle Stack + Load Length + 12 inches for safe space. - Always look at your forklift manual and OSHA rules. This helps keep your warehouse safe and working well.

Forklift Aisle Width Formula

When you plan your warehouse, you need to know the right aisle width for your forklift. The aisle width formula helps you find the safest and most efficient space for forklift movement. You can use this formula for any warehouse aisle dimensions.

Minimum Forklift Aisle Width Components

The industry-accepted aisle width formula is:

Minimum Aisle Width = Right Angle Stack + Load Length + 12 inches

You use three main parts in this calculation:

Right Angle Stack: This is the smallest space your forklift needs to turn and place a load at a right angle. For many forklifts, this is about 94.3 inches.

Load Length: This is the length of the pallet or load you carry. Most standard pallets are 48 inches long.

Clearance: You add 12 inches for safe clearance. This extra space helps you avoid hitting racks or other objects.

Here is a quick look at these numbers:

| Component | Typical Measurement |

|---|---|

| Right Angle Stack | 94.3 inches |

| Load Length | 48 inches |

| Clearance | 12 inches |

| Total | 154.3 inches |

So, the minimum forklift aisle width in this example is 154.3 inches, or about 12.9 feet.

Right Angle Stack and Load Length

You need to measure the right angle stack for your specific forklift. This number tells you how much space your forklift needs to turn and set down a load at a 90-degree angle. If you use a larger forklift, the right angle stack will be bigger. Smaller forklifts need less space.

The load length is just as important. Most warehouses use standard pallets, which are 48 inches long and 40 inches wide. Some pallets are larger, so always check your pallet size before you start your aisle width calculation.

| Pallet Size | Dimensions (inches) | Dimensions (cm) |

|---|---|---|

| Standard Size | 48 x 40 | 121.9 x 101.6 |

| Other Sizes | 60 x 60, 48 x 48 | Various |

The right angle stack measurement is essential for calculating the minimum aisle width needed for forklift operations.

The aisle width formula uses the right angle stack, load length, and 12 inches of clearance.

The extra 12 inches lets you move the forklift safely in the aisle.

Clearance and Safety

You must always add clearance for safety. The 12-inch clearance in the aisle width formula gives you room to maneuver and helps prevent accidents. OSHA recommends that forklifts stay at least five feet away from pedestrians. You should also drive slowly in areas with people.

When you choose your warehouse aisle dimensions, you need to balance space and safety. Wide aisles make it easier to move and turn, but they take up more room. Narrow aisles save space but require special forklifts and careful driving.

Here is a table of standard aisle width requirements for different forklift types:

| Forklift Type | Aisle Width Requirement |

|---|---|

| Conventional Forklifts | 12 to 13 feet |

| Narrow Aisle Forklifts | 8 to 10 feet |

| Very Narrow Aisle Forklifts | 6 feet or less |

OSHA does not give exact numbers for minimum aisle width, but it does stress the need for enough space to avoid collisions. Manufacturers often provide their own recommendations based on the type of forklift you use.

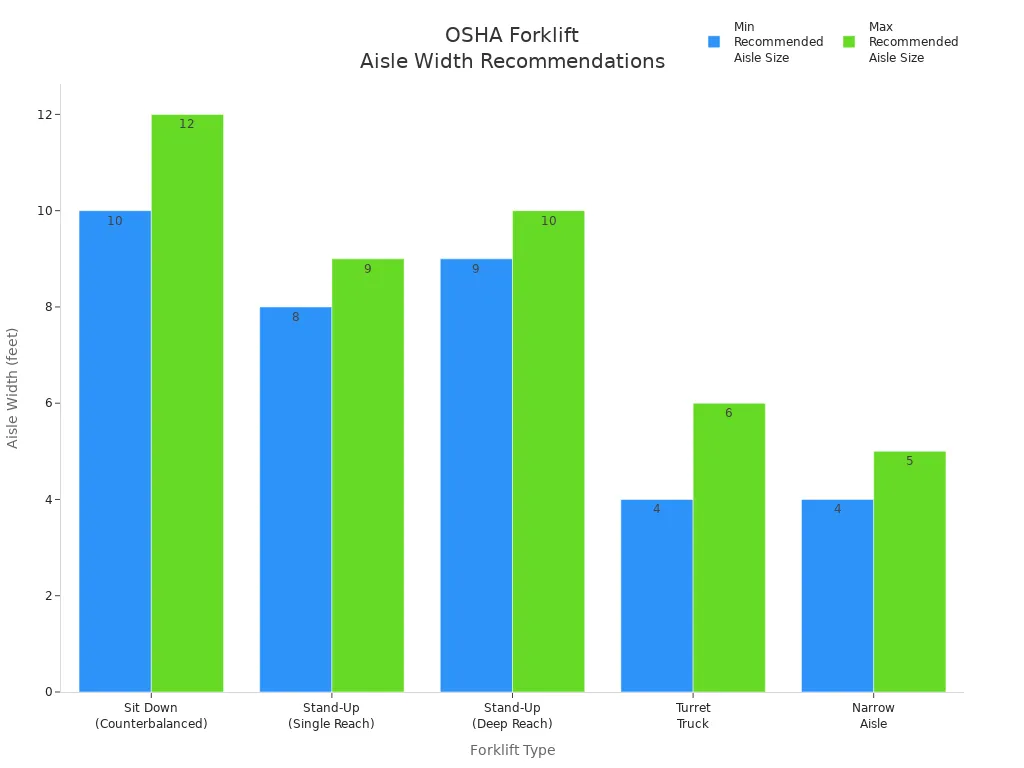

You can also see the OSHA recommended aisle sizes for different forklift types in the chart below:

Tip: Always check your forklift manual and OSHA guidelines before you set your aisle width. This helps you keep your warehouse safe and efficient.

Calculate Minimum Aisle Widths: Steps

Sample Calculation

You can calculate minimum aisle widths for your warehouse by following a clear process. This helps you keep your warehouse operations safe and efficient. Here is a step-by-step example using real forklift dimensions:

Find the right angle stacking width

Check your forklift manual for this number. For this example, use 94.3 inches.Add the load length

Most standard pallets are 48 inches long. Use this number unless your pallets are a different size.Add clearance for safety

Always add 12 inches to give your forklift room to move without hitting racks or other objects.Consider pallet overhang

Pallet overhang usually ranges from 3 to 6 inches on each side. For this example, add 6 inches to your total.

Here is how your calculation looks:

Minimum Aisle Width = Right Angle Stack + Load Length + Clearance + Pallet Overhang Minimum Aisle Width = 94.3" + 48" + 12" + 6" = 160.3"

You can convert 160.3 inches to feet by dividing by 12. This gives you about 13.4 feet. This number tells you the minimum space you need between racks for your forklift to turn and stack pallets safely.

Tip: Always measure your actual pallets and check for any extra overhang. This helps you avoid mistakes in your aisle width calculation.

Interpreting Results

After you calculate minimum aisle widths, you need to understand what the results mean for your warehouse. If your calculation gives you 13.4 feet, you know that your aisles must be at least this wide for safe forklift movement.

If you use wide aisles, you make it easier for forklifts to turn and move. This can speed up warehouse operations.

If you want to save space, you might try narrower aisles. You must use special forklifts for very narrow aisles and drive with extra care.

When you interpret your results, always check these points:

Make sure your forklift can turn without hitting racks or other loads.

Check if your pallets have extra overhang. Even a few inches can make a big difference.

Review your racking system. Some racks need more space for safe loading and unloading.

Note: Calculating aisle width is not just about fitting your forklift. You must also think about safety, pallet size, and how your team works in the space.

If you use different forklifts or handle larger loads, repeat the calculation for each case. This helps you plan your warehouse layout and avoid costly changes later.

By following these steps, you can calculate minimum aisle widths that fit your needs. You keep your team safe and your warehouse running smoothly.

Forklift Aisle Width Minimums: Factors

Forklift Types

You must pick the right forklift for your warehouse. Each forklift type needs a different aisle width. Conventional forklifts need wide aisles, about 12 to 13 feet. They have a big turning radius, so they need more space. Electric rider forklifts can work in aisles as small as 10.5 to 12 feet. Single reach trucks fit into 9-foot aisles. Specialty forklifts can use aisles as narrow as 6 feet. Very narrow aisles give you up to 50% more floor space. But you need skilled workers and special machines for these aisles. The turning radius of your forklift is important for safety. Forklifts with smaller turning radii turn better in tight spaces. This helps you avoid crashes.

Load and Pallet Size

You should think about your load and pallet size when planning. Standard pallets are 48 by 40 inches. Some warehouses use bigger or custom pallets. Bigger loads need more space to turn and stack. Busy seasons may change your aisle size needs. You might need to move things around to fit more products. Narrow aisles let you store more, but movement is harder. Wide aisles make it easier to drive, but you lose storage space. Always match your aisle width to the loads you use.

Safety and Clearance

Safety is very important in a warehouse. Keep aisles clear and use barriers to protect people. OSHA says forklifts should stay at least five feet from people. Good lighting and smooth floors help stop accidents. Operators must have the right training and certification. If you cannot keep enough space, add rack protection to stop pallets from falling. New warehouse designs use automated guided vehicles and real-time tracking. These tools help you watch your layout and keep things running well.

Tip: Always check your forklift specs and warehouse layout before making changes. This helps you keep the right aisle width and keeps everyone safe.

To figure out the smallest aisle width, do these steps:

Look up your forklift’s right angle stacking width.

Add the length of your biggest load.

Put in 12 inches for extra space.

You can plan your warehouse better by checking forklift specs and OSHA rules. Safe aisle widths help stop accidents and make work go smoothly.

FAQ

What happens if your aisle is too narrow for your forklift?

You risk damaging racks, pallets, or your forklift. Narrow aisles can slow down work and increase the chance of accidents.

How do you measure the right angle stack for your forklift?

Check your forklift manual for the right angle stack measurement. You can also ask your dealer or manufacturer for this number.

Do OSHA rules set a minimum aisle width for forklifts?

OSHA does not give a specific number. You must provide enough space for safe movement and avoid collisions in your warehouse.

English

English