AUGUST 26, 2025

Electric forklifts vs. gas forklifts: which is better

Choosing the right forklift depends on what you need. There are important differences that help you decide. Electric forklifts are clean and quiet. They work best indoors. These forklifts now make up more than 66% of all forklift sales. This shows people want more eco-friendly options. Gas forklifts are strong and tough. They do well outside in hard conditions.

The table below shows where each type works best:

| Forklift Type | Common Environments | Typical Use Cases |

|---|---|---|

| Electric forklift | Indoor, clean, quiet spaces | Warehouses, food and beverage, pharma |

| Gas forklift | Outdoor, heavy-duty, rough terrain | Construction, agriculture, lumber |

Looking at both types side by side can help you choose the right one for your job.

Key Takeaways

Electric forklifts are quiet and clean. They work best inside buildings. They help save money on fuel and repairs over time.

Gas forklifts are strong and can refuel fast. They work well outside on rough ground and with heavy things.

Electric forklifts cost more at first because of batteries. But they cost less to run and break down less often.

Gas forklifts can lift heavier things faster. But they need more repairs and make more noise and pollution.

Picking the right forklift depends on where you work. It also depends on what you need to lift, your budget, and safety needs.

Cost

Upfront Cost

When you look at electric forklifts and gas forklifts, you see different starting prices. New electric forklifts usually cost between $25,000 and $55,000. This does not count the price of batteries or chargers. Batteries and chargers can add $10,000 to $20,000 more. The extra cost depends on the battery type and forklift size. Gas forklifts, like propane and diesel, cost from $25,000 to $60,000. If you need a 3,000 lb. forklift, electric ones cost about $36,500 to $39,500. Gas forklifts for the same size cost $29,500 to $32,000.

The battery is a big part of the upfront cost for electric forklifts. Lithium-ion batteries cost more than lead-acid batteries. They last longer and need less care.

| Forklift Size | Typical Lithium Battery Price Range |

|---|---|

| Small (24V / 200Ah) | $3,000 – $5,000 |

| Medium (36V / 400Ah) | $7,000 – $10,000 |

| Heavy-duty (48V / 600–700Ah) | $12,000 – $20,000+ |

| Forklift Type | Capacity | Upfront Cost |

|---|---|---|

| ICE Forklift | 2,500 kg | £20,000 |

| Electric Forklift (with battery and charger) | 2,500 kg | £25,000 |

Lithium-ion batteries can cost two to three times more than lead-acid batteries. The higher price might surprise some buyers. These batteries last longer and work better. The battery and charger together can add about £5,000 to the price of an electric forklift compared to a gas one.

Operating Cost

Electric forklifts are cheaper to run. They use electricity, which costs less than gas or propane. Electric forklifts cost $1.50 to $2.50 per hour to use. Gas forklifts cost $3.25 to $4.75 per hour. Over a year, electric forklifts save 30% to 40% on fuel.

| Forklift Type | Fuel Type | Average Fuel Cost per Hour | Annual Maintenance Cost Range (Light-Duty) |

|---|---|---|---|

| Electric Forklift | Electricity | $1.50 - $2.50 | $750 - $1,200 |

| Gasoline Forklift | Gasoline | $3.25 - $4.75 | Higher than electric |

Electric forklifts need less service because they have fewer moving parts. Yearly maintenance for electric forklifts is $750 to $1,200. Gas forklifts need more checks, like oil changes and filter swaps. This makes their maintenance cost more. Electric forklift batteries need replacing every 5 to 7 years and cost $5,000 to $8,000. Even with this, electric forklifts still cost less to own over time.

Electric forklifts save money on fuel and maintenance. Their total cost is lower, even if monthly lease payments are a bit higher.

Long-Term Value

A forklift’s long-term value depends on how long it lasts, how much care it needs, and its total cost. Both electric and gas forklifts last about 10,000 to 20,000 hours. Electric forklifts often last longer because they have fewer moving parts. But you need to plan for battery replacement, which can be expensive.

| Aspect | Electric Forklifts | Propane Forklifts |

|---|---|---|

| Typical Operating Hours | 10,000 to 20,000 hours | 10,000 to 20,000 hours |

| Battery/Fuel Source Lifespan | Lead-acid battery: ~5 years; Lithium-ion: up to 10 years | Propane tank: up to 20 years |

| Maintenance Cost per Hour | $0.90 | $1.15 |

| Monthly Maintenance Cost | $108 | $138 |

| Total Savings Over 5 Years | ~$7,120 less (electric) | N/A |

In five years, electric forklifts can save about $7,120 in fuel and maintenance. Their total cost is lower because they use less fuel and need less service. Good care can help both types last up to 30% longer. Electric forklifts are efficient and reliable. They are a smart pick for companies that want to save money in the long run.

Performance

Power & Capacity

How much a forklift can lift is very important. Gas forklifts are strong and fast. They are good for heavy jobs and outside work. These forklifts can lift 8,000 pounds or more. This makes them great for building sites and lumber yards. Electric forklifts can lift about 3,000 to 4,000 pounds. Most electric forklifts work best inside. They are used where it needs to be quiet and clean.

| Forklift Type | Typical Maximum Load Capacity | Typical Use Environment |

|---|---|---|

| Electric Forklift | Around 3,000 to 4,000 pounds | Indoors (battery powered, no emissions) |

| Gas Forklift | Up to 8,000 pounds or more | Outdoors (gas or diesel powered) |

Gas forklifts are better for lifting very heavy things fast. Their engines make them go quicker and lift faster than electric ones. Electric forklifts have enough power for most warehouses. But they may not speed up as fast when lifting heavy loads.

| Aspect | Gas Forklifts | Electric Forklifts |

|---|---|---|

| Acceleration | Generally faster; better for demanding tasks | Slower, especially under heavy loads |

| Lifting Speed | Higher, efficient for heavy loads | Lower, sufficient for standard tasks |

Tip: If you need to move big or heavy things outside, gas forklifts work best and save time.

Runtime & Refueling

How long a forklift works before stopping is important. Electric forklifts can run for about 8 hours on one charge. If the job is easy and has breaks, they can last up to 12 hours. Old batteries may only last 3 hours if used all the time. Gas forklifts, like propane ones, run for 6 to 8 hours on one tank. Bigger engines may not last as long. Changing a propane tank takes just a few minutes.

| Engine Type / Tank Size | Average Runtime per Tank |

|---|---|

| 4-cylinder engine with 8-gallon tank | ~8 hours |

| V6 engine with 8-gallon tank | ~6 hours |

| Larger engines with 10-gallon tank | ~6 hours |

| Extended runtime with engine off when idle | Up to 10-12 hours |

It takes much longer to charge an electric forklift than to refuel a gas one. Electric forklifts need 6 to 8 hours to charge their batteries. This means they cannot be used during that time. Propane forklifts can be ready in about 5 minutes by changing the tank.

| Forklift Type | Recharge/Refuel Time |

|---|---|

| Electric Forklift | 6 to 8 hours recharge time |

| Propane Forklift | About 5 minutes to swap tank |

Electric forklifts need up to 8 hours to charge.

Propane forklifts can be ready in about 5 minutes.

Fast propane refueling helps keep work going.

Note: Companies that work many shifts often pick propane forklifts. They like the quick refueling and steady work.

Maneuverability

Electric forklifts are easy to move in small spaces. Their small size and tight turning help in narrow aisles. They run quietly and smoothly. This helps workers talk and stay safe. Gas forklifts are bigger and not as easy to turn. They work best outside where there is lots of space.

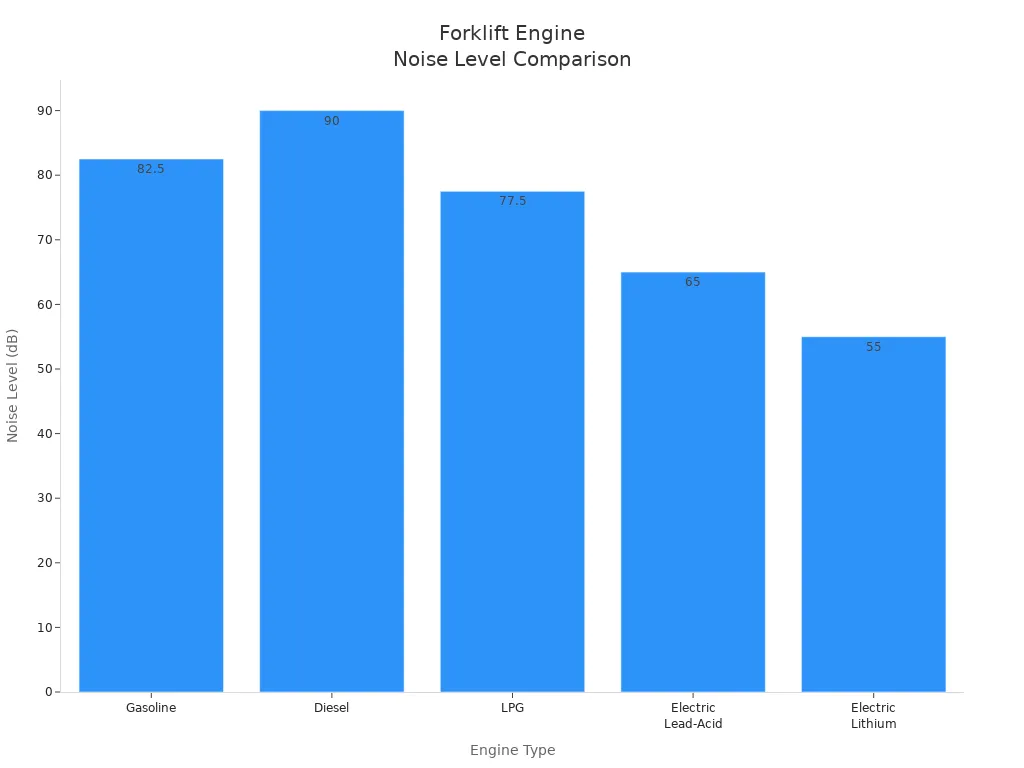

Noise matters too. Electric forklifts are not very loud. They make about 60 to 70 decibels of noise, like people talking. Gas forklifts are louder, often over 85 decibels. This can mean workers need ear protection.

| Engine Type | Noise Level (dB) Range | Notes and Context |

|---|---|---|

| Gasoline | 75 - 90 | Moderate to high noise, especially on acceleration |

| Diesel | 85 - 95 | Louder than gasoline, distinct knocking sound |

| LPG | 70 - 85 | Quieter than gasoline and diesel |

| Electric (Lead-Acid) | 60 - 70 | Minimal noise from motor and cooling fan |

| Electric (Lithium Battery) | Below 60 | Extremely quiet, ideal for noise-sensitive environments |

Lower noise from electric forklifts makes work safer and more comfortable. They help workers focus and talk to each other easily.

Maintenance

Service Intervals

Manufacturers say electric and gas forklifts need service at different times. Electric forklifts should get checked every 500 hours. These checks look at the motor and cables. Workers also add grease to moving parts. The battery needs care, and safety features get checked too. Gas forklifts need service more often, about every 250 hours. Their service means changing engine oil and filters. Parts get greased, and systems are checked for problems. How often you use the forklift and where you use it can change how much service it needs.

Electric forklifts: Check every 500 hours (motor, cables, grease, battery, safety).

Gas forklifts: Check every 250 hours (engine oil, filters, grease, system checks).

Both types: Need more checks if used a lot or in tough places.

Doing regular service keeps forklifts safe and helps them last longer.

Repair Costs

Electric forklifts have fewer parts that move, so repairs cost less. They do not need engine oil or fuel filter changes. Most repair costs come from taking care of the battery or getting a new one. A new battery costs $2,000 to $6,000 and lasts 5 to 10 years. Gas forklifts need oil changes, new filters, and engine tune-ups. Fixing the engine can cost $1,000 to $5,000. Fixing the transmission can cost $8,000 to $13,000.

| Component | Electric Forklift Costs | Gas Forklift Costs |

|---|---|---|

| Battery Replacement | $2,000 - $6,000 | N/A |

| Engine Replacement | N/A | $1,000 - $5,000 |

| Transmission Replacement | N/A | $8,000 - $13,000 |

| Hydraulic System Repair | ~$1,800 | ~$1,800 |

| Tire/Wheel Replacement | Hundreds to thousands of dollars | Hundreds to thousands of dollars |

Parts & Reliability

Electric forklifts have fewer parts that can break. They do not have engines or transmissions, so they shake less and need less care. Most problems come from batteries or electrical parts. Gas forklifts have more parts in their engines and fuel systems. If propane systems are not cared for, repairs and fuel costs go up. Both types need regular checks to work well, but electric forklifts usually last longer and have fewer problems.

Environmental Impact

Emissions

Forklifts can affect the environment in different ways. Electric forklifts are better for the environment. They use less energy and do not make much pollution. They do not give off fossil fuel emissions when working. Gas forklifts, like diesel ones, put more carbon into the air. The table below shows how much carbon dioxide each type makes every hour:

| Forklift Type | Average CO2 Emissions per Hour (kg) | Relative Emissions Compared to Electric |

|---|---|---|

| Diesel (Gas) Forklift | 10.2 | 8 times higher |

| Electric Forklift | ~1.275 | Baseline |

Electric forklifts make less carbon. This helps companies reach their green goals. Gas forklifts make more pollution and dirty exhaust. This is a problem for companies that want clean air.

Noise

Noise can change how workers feel at work. Electric forklifts are quiet. This makes them good for inside jobs. Gas forklifts are louder and make dirty air. This can bother workers and make inside work less safe. Electric forklifts help keep the air clean and the noise low. This makes work more comfortable and protects people’s hearing.

Regulations

Many places have rules about forklift pollution. Cities have strict laws for emissions. These laws follow American and European standards. The rules try to lower fossil fuel pollution and carbon in the air. Gas forklifts must follow these rules to be used. Companies must store and use gas cylinders safely to stop accidents. Cities often do not allow diesel forklifts because they make too much pollution. They want gas forklifts that meet the rules. Electric forklifts have fewer rules because they do not make tailpipe pollution. Companies that care about the environment often pick electric forklifts. This helps them follow the rules and lower their carbon footprint.

Safety

Operator Safety

Electric forklifts and gas forklifts keep operators safe in different ways. Electric forklifts use batteries, so they do not need flammable fuel. This lowers the chance of fire or explosion from fuel. Some electric forklifts are made for dangerous places:

E rated: Basic safety, good for safe areas.

EE rated: Extra safety for electrical parts, less fire risk.

EX rated: Explosion-proof, with spark-free circuits and special tires.

EX rated forklifts need special training to fix them. These forklifts work well where there is explosive dust or gas.

Gas forklifts use fuels like LPG or CNG. These fuels can leak and build up in closed spaces. This can cause explosions. Gas forklifts can catch fire from open flames, high heat, or electrical problems. Their electrical systems can start fires if not checked often. Checking fuel lines and electrical parts helps stop accidents. Operators must follow strict safety steps to keep everyone safe.

Tip: Companies should teach all forklift operators how to shut down forklifts in emergencies and do safety checks.

Workplace Hazards

Workplace dangers are different for electric and gas forklifts. Gas forklifts have more risks because they use fuel that can burn and things that can start fires. Dangers include:

Fumes and exhaust that need good airflow.

Sparks from the engine or electrical parts.

Hard emergency steps, like turning off the ignition, closing the fuel valve, and sealing the tank.

The engine must cool down before shutting off, which can slow down emergency help.

Electric forklifts do not make exhaust fumes. Operators can turn them off fast by disconnecting the battery. This easy step lowers dangers from fumes and sparks. Electric forklifts do not use fuel that can burn or make emissions. This makes them safer inside and helps keep workers safe.

Flexibility

Indoor Use – Electric Forklift Trucks

Electric forklift trucks are great for working inside. They do not make any emissions, so they are good for places like warehouses and food plants. These forklifts are quiet, which helps keep work safe and comfortable. Their small size lets them move easily in tight spots and narrow aisles. Many companies pick electric forklifts because they work well and do not need much fixing.

But electric forklifts can have problems in very cold places. Batteries do not work as well when it is really cold. This makes them less reliable and harder to use all the time. The table below shows how electric and gas forklifts work in cold storage:

| Aspect | Electric Forklifts | LPG (Gas) Forklifts |

|---|---|---|

| Suitable Environment | Indoor clean environments, noise-sensitive areas, cold chain storage | Indoor/outdoor mixed, low temperature environments, high-intensity continuous operation |

| Performance in Cold Storage | Battery performance degrades significantly at low temperatures (e.g., -20°C), limiting reliability | Power source less affected by cold, reliable at very low temperatures (e.g., -25°C) |

| Operational Advantages | Zero emissions, low noise, suitable for regulated environments | Fast refueling, strong power, better for heavy loads and continuous use |

| Limitations | Battery prone to failure in very cold conditions, limited continuous operation time | Emissions and noise, less suitable for strict indoor clean environments |

Electric forklifts are still the best for most inside jobs. But workers should remember that batteries do not last as long in the cold.

Outdoor Use – Gas Forklifts

Gas forklifts, like propane forklifts, work well outside. They can handle rough ground, heavy things, and long hours without stopping. Propane forklifts can be refueled quickly, so workers do not have to wait long. Electric forklifts may not do as well outside, especially on bumpy or wet ground.

Gas forklifts can have problems in bad weather:

They can get too hot if not cared for, like when coolant is low or filters are dirty.

Dust and dirt from outside can get into the engine and make it overheat.

Driving too fast or carrying too much weight can break the forklift.

In cold weather, propane forklifts need a few minutes to warm up.

Frost can form on the LPG vaporizer, which can stop the engine.

Stopping and starting a lot in the cold can make frost worse.

Outdoor forklifts should have cabs to keep drivers warm, because cold drivers get tired and work slower.

Manufacturers make things like heat shields and special vents to help gas forklifts work better in tough weather. Taking care of the forklift and using it the right way helps propane forklifts work well all year.

Application Suitability

Electric Forklifts for Warehouses

Electric forklifts are very important in warehouses. They do not make emissions and are quiet. This makes them great for working inside. Workers use them to move things, stack pallets, and load trucks. There are different classes of electric forklifts for different jobs.

| Forklift Class | Typical Types | Common Warehouse Applications |

|---|---|---|

| Class 1 | 3-wheel and 4-wheel counterbalance | Loading and unloading trucks, stacking pallets, moving goods inside |

| Class 2 | Narrow aisle forklifts, reach trucks, stackers | Storing lots of items, getting goods from high shelves |

| Class 3 | Electric pallet jacks, walkie stackers, order pickers | Moving pallets short distances, working in stores and small centers |

Warehouse managers like electric forklifts because they fit in small spaces. They are used in stores, food places, and medicine companies. These forklifts help keep places clean and safe. They are good for cold storage and hospitals. Electric forklifts also make less noise, so workers can talk and stay safe.

Tip: Electric forklifts work well for moving things in warehouses, especially where clean air and quiet are needed.

Gas Forklifts for Heavy Loads

Gas forklifts, like propane forklifts, are strong and tough. They are used on building sites and in factories. These forklifts have powerful engines and steady power. Propane forklifts lift big things and work on rough ground.

| Aspect | Gas Forklifts | Electric Forklifts |

|---|---|---|

| Power Source | Internal combustion (gas, propane) | Battery-powered |

| Load Handling | Heavy loads, rough ground | Lighter loads, smooth floors |

| Refueling | Fast propane tank change | Longer battery charging |

| Environment | Outside, heavy work | Inside, clean places |

Propane forklifts can refuel fast, so work does not stop. Their engines keep lifting well, even when fuel is low. These forklifts work in all kinds of weather, so they are good outside. Gas forklifts need regular care, like engine checks and oil changes. But they last a long time and are good for hard jobs.

Note: Propane forklifts are best for jobs that need to move heavy things fast and work outside in tough places.

Decision Checklist

Quick Comparison Table

| Criteria | Electric Forklift | Gas Forklift (LPG/Diesel) |

|---|---|---|

| Load Capacity | Can lift up to 4,000 lbs | Can lift over 8,000 lbs |

| Terrain | Works best on smooth indoor floors | Handles rough outdoor ground |

| Emissions | Makes no emissions | Makes fumes, not good indoors |

| Noise Level | Runs quietly | Is loud, may need ear protection |

| Maintenance | Needs less fixing, fewer parts | Needs more engine care |

| Refueling/Charging | Needs 6-8 hours to charge | Refuels fast with tank swap |

| Upfront Cost | Costs more for battery and charger | Costs less, but fuel costs more |

| Service Life | Lasts long, breaks down less | Reliable, especially outside |

| Safety | No flammable fuel, safer inside | Fuel can be risky, hard to see |

| Flexibility | Great for warehouses, indoor jobs | Great for outside, heavy lifting |

Tip: New lithium-ion batteries charge faster and last longer. This helps electric forklifts catch up with gas forklifts.

Key Questions

Before picking a forklift, people should ask:

What is the heaviest thing the forklift will lift?

Will it be used inside, outside, or both?

Are there tight aisles or tall shelves that make turning hard?

How many hours each day will it be used?

Is quiet work or clean air important at the job site?

Can you fix and find parts for each forklift type?

Are there special safety rules for workers or the place?

Can you pay more now to save money later?

Do you need quick refueling or charging to keep working?

Has your team tried different forklifts to see which fits best?

Experts say you should match the forklift to your job, ground, and how much you need to lift.

Companies should look at dealer trust, help after buying, and repair plans.

Trying out forklifts helps you pick the best one for your work.

Picking the right forklift makes work safer, faster, and saves money for your business.

Electric forklifts are quiet and need less fixing. They do not make any emissions. Gas forklifts are strong and can refuel quickly. They are good for heavy jobs outside. Each forklift type is best for different jobs. The right one depends on where you work. Look at the checklist and table before you choose. Experts say to talk to a forklift dealer for help.

Tip: Planning ahead helps companies pick the safest and best forklift.

FAQ

How long does it take to charge an electric forklift?

Most electric forklifts take 6 to 8 hours to charge. Some lithium-ion models can charge faster than others. Quick charging stations help save time. Operators should charge forklifts during breaks or after work.

Can gas forklifts be used indoors?

Gas forklifts can be used inside, but they make fumes. Good airflow is needed to keep the air safe. Many companies pick electric forklifts for indoor jobs because they do not make exhaust.

What is the average lifespan of a forklift?

A forklift that gets good care lasts 10,000 to 20,000 hours. Electric forklifts often last longer since they have fewer moving parts. Regular service helps both types last longer.

Are electric forklifts safe in wet conditions?

Electric forklifts can work in light rain or damp spots. Operators should stay away from deep water and puddles. Most electric forklifts are made for indoor use. Special models are needed for outdoor work in wet weather.

Do electric forklifts need special maintenance?

Electric forklifts need less fixing than gas forklifts. Operators should check batteries, cables, and safety parts often. Taking care of the battery helps it work better and last longer.

English

English