AUGUST 25, 2022

What is a Fork Truck Lifting Boom and How Does It Work

A fork truck lifting boom is also called a forklift boom or jib boom. It connects to your forklift truck and makes it work like a crane. You can lift and move heavy things high up. You can reach over things and put loads on platforms or trucks. When you add a boom, your forklift truck stays easy to drive. You can now do new lifting jobs. You can use a fork truck lifting boom in many places. Some examples are below:

| Industrial Sector | Application Details |

|---|---|

| Construction | Building projects, urban development |

| Manufacturing | Warehouses, assembly lines, material handling |

| Mining | Loading, unloading, maintenance |

| Logistics & Transport | Warehousing, distribution, e-commerce operations |

Key Takeaways

A fork truck lifting boom makes a forklift work like a crane. It helps you lift heavy or odd-shaped things higher and farther than normal forks can.

There are two main types. Telescopic booms can stretch out for more reach. Non-telescopic booms lift things straight up and are steadier.

Always put the boom on tightly and follow safety rules. Check the equipment, wear safety gear, and never lift more than the weight limit.

Forklift booms help save time and money. They let you reach farther and do more jobs with one forklift. They also cut down on hard work by hand.

Only trained people should use forklift booms. Use them on flat, steady ground. They work best inside or on smooth floors. Cranes are better for heavy jobs outside.

Fork Truck Lifting Boom Overview

Definition

You may hear people call this tool a fork truck lifting boom, forklift boom, or jib boom. Each name describes the same attachment. You connect it to your forklift truck to turn it into a lifting machine. This tool helps you pick up loads that hang from hooks or chains. You can move items that are too large or awkward for standard forklift forks. Forklift booms stand out from other attachments because of their special features:

You can attach the boom directly to the forklift mast or slide it over the existing forks.

Mast-mounted booms give you more lifting power because they keep the center of gravity low.

Some forklift booms have a fixed length. Others are telescoping, so you can adjust the reach. Telescoping booms sometimes use hydraulic controls for easy changes.

Certain booms have pivot points. These let you swing loads side to side, giving you better control.

With these features, your forklift truck works like a mobile crane. You get more reach and flexibility than with regular attachments.

Basic Function

When you use a fork truck lifting boom, you change the way your forklift truck handles loads. You attach the boom by sliding it onto the forks. You secure it with pins behind the heel of each fork. Safety chains or hooks wrap around the fork carriage. Locking grab hooks keep everything in place. The lifting hook on the boom has a spring latch. This latch stops slings or chains from slipping off. Telescoping booms use spring-loaded pins and internal stops. These features prevent the boom from extending too far.

Here is how you attach and use a forklift boom safely:

Slide the boom onto the forklift forks.

Pin the boom behind the heel of the forks.

Secure retaining pins with hairpins or cotter pins.

Wrap safety chains or hooks around the fork carriage.

Lock the chains with grab hooks.

Check the lifting hook for a working spring latch.

Inspect all shackles, hooks, and pins before lifting.

You use a fork truck lifting boom to lift suspended or oversized loads. You can reach over obstacles and place items on high platforms or trucks. This tool helps you handle loads that regular forklift forks cannot manage. You get more control and safety when moving heavy items. Forklift booms make your forklift truck more versatile and valuable in many workplaces.

Types of Forklift Boom

Telescopic

Telescopic forklift booms are used on many job sites. These booms have parts that slide inside each other. You can make them longer or shorter with hydraulic controls. This design helps you reach higher and farther than a regular forklift truck. Telescopic forklift booms act like a crane mast on a forklift truck. You can put loads over things or into high places. Some models, such as the JLG 860SJ, can go up to 86 feet high and reach out 75 feet. You can use these forklift booms outside, even on rough ground. Many have all-terrain tires and four-wheel drive. Telescopic forklift booms help you lift things to upper floors or across gaps. They are often used in warehouses and on construction sites.

Tip: Telescopic forklift booms let you reach farther and higher. You can do jobs that regular forklift trucks cannot handle.

Non-Telescopic

Non-telescopic forklift booms have a simple design. They have a vertical mast that moves the forks up and down. Sometimes, you can tilt the mast forward or backward. These forklift booms do not stretch out like telescopic ones. You use them for lifting things straight up and stacking them. Non-telescopic forklift booms are more stable because they are strong and sturdy. You will see these forklift booms where you need to lift loads right in front of the forklift truck. They are good for loading and unloading things at ground level.

| Feature | Telescopic Forklift Boom (Telehandler) | Non-Telescopic Forklift Boom (Straight Mast) |

|---|---|---|

| Boom Structure | Parts slide inside each other, moved by hydraulics | Vertical mast lifts forks up and down, sometimes tilts |

| Reach | Can go up and forward, up to 50+ feet | Mostly lifts up, not far forward |

| Typical Applications | Putting loads on high floors, over ditches, across gaps | Stacking things, loading and unloading at ground level |

| Versatility and Attachments | Many tools: forks, buckets, grapples, winches, platforms, clamps | Mostly uses forks; sometimes buckets, grapples, jibs |

| Stability | Less steady when stretched out with heavy loads | More steady because of simple mast |

| Design Resemblance | Looks like a crane mast on a forklift truck | Looks like a regular forklift truck |

Common Uses

Forklift booms are used in many industries. In construction, you use forklift booms to lift steel beams, pipes, and concrete blocks to higher floors or over things. In manufacturing, forklift booms help move heavy machines and equipment carefully. Forklift booms are common in warehouses for moving big pallets and containers. You can reach high shelves and tight spots that regular forklift trucks cannot get to. In mining and heavy industries, forklift booms lift and move heavy equipment and materials. Forklift booms make work safer and easier. You get better control and save time in your daily work.

| Industry Sector | Common Applications of Forklift Booms | Benefits and Uses |

|---|---|---|

| Construction | Lifting heavy, oddly shaped things to higher floors or over obstacles | Makes work faster; less manual lifting |

| Stone Fabrication | Moving big stone slabs safely and easily | Less damage and less manual work |

| Warehousing and Distribution | Lifting and moving pallet goods, working in narrow aisles, reaching high shelves | Saves space and makes moving loads easier |

Operation and Safety

Attachment to Forklift

You must make sure the boom is attached tightly before lifting. Most forklift booms slide over the forks. Heavy pins lock the boom behind each fork’s heel. Safety chains wrap around the fork carriage. These chains connect to locking grab hooks. The chains stop the boom from moving while you work. Some booms attach right to the mast for more stability. Always check that every pin, chain, and hook is tight. Look at the lifting hook to see if the spring latch works. This latch keeps slings or chains from falling off. If you use a telescopic boom, check the spring pins and stops. Follow the instructions from the manufacturer for your forklift attachment. A tight connection keeps you safe and protects your forklift.

Tip: Always check the forklift boom before you use it. Look for worn pins, loose chains, or broken hooks.

Load Capacity

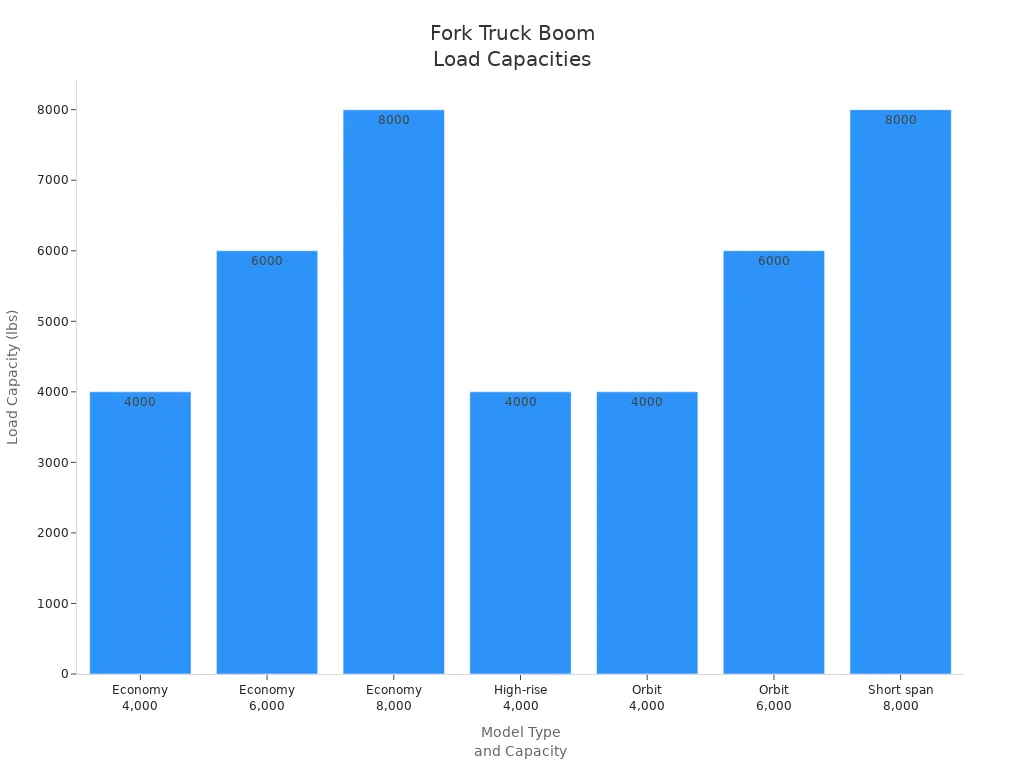

You need to know how much weight your forklift and boom can lift. Most warehouse forklifts lift 3,000 to 5,000 pounds. Big outdoor forklifts can lift 15,000 pounds or more. The load center changes how much you can lift. If the weight is not balanced, you lose lifting power and stability. Different booms have different load ratings. Here is a table with some examples:

| Model Type | Load Capacity (lbs) | Notes |

|---|---|---|

| Economy non-telescoping | 4,000 / 6,000 / 8,000 | Multiple models with these capacities |

| High-rise non-telescoping | 4,000 | Specific high-rise boom model |

| Orbit non-telescoping | 4,000 / 6,000 | Different orbit boom models |

| Short span non-telescoping | 8,000 | Short span boom model |

Most forklift booms can lift between 4,000 and 8,000 pounds. Always look at the rating tag before lifting anything. Hydraulic systems power the boom and lifting parts. Fluid pressure helps the boom lift heavy things. The hydraulic system’s strength changes how much you can lift. The maximum load depends on boom length, angle, and stability. Manufacturer charts show safe lifting limits. Hydraulic controls help you move loads smoothly and safely. If you lift too much or work on uneven ground, you can lose stability. Hydraulic systems give you lifting power and control, but you must think about design and working conditions.

Safety Precautions

You must follow safety rules when using a forklift boom. Operators need training and certification. You must know how the forklift and boom work. Always check everything before you start. Look at the vehicle, boom controls, safety devices, and ground support. Wear a harness and belt for fall protection. Stay at least 10 feet away from power lines. Never use the boom as a crane or go over weight limits. Do not move the lift while it is up unless the manufacturer says it is safe. Stay inside the lift platform. Never climb or sit on rails or edges. Do not turn off safety features or skip safety steps.

Here are important safety steps:

Check the forklift and boom before each use.

Wear safety gear like hard hats, harnesses, and shoes.

Follow the weight limits for people and materials.

Work on flat, stable ground and use outriggers if needed.

Watch for things above you like power lines.

Move slowly and carefully to avoid sudden jolts.

Do not work in bad weather like wind or rain.

Never skip emergency stops or guardrails.

Follow the manufacturer’s instructions for use and care.

Make sure you have training and certification.

You must follow safety rules at work. Write down all inspections, training, and maintenance. Only certified operators who are at least 18 years old can use a forklift. Forklift rating tags must match the forklift setup. Fall protection must meet OSHA rules. Platforms must have clear weight limits and follow ANSI and OSHA rules. Check your forklift and boom every day. Remove unsafe equipment right away. Employers must keep records of training and certification. Retrain every three years or after an accident. These rules keep you safe and help you follow the law.

Benefits

Increased Reach

Forklift booms help your forklift reach farther. You can lift things higher than regular forklift tines. You can get items from tall shelves and tight spots. You can move long or big things easily. Forklift booms make your forklift work like a small crane. You can change the angle and how much it lifts. This helps you work safely and quickly in places like warehouses or construction sites.

Tip: Forklift booms let you reach places regular forklifts cannot. You can store more things and use your space better.

Here is a table that shows how reaching farther helps you work better:

| Benefit Category | Description | Measurable Impact / Example |

|---|---|---|

| Maneuverability | Reach trucks fit in narrow aisles and tight spaces. They turn in small areas. | Aisles can be 30% smaller, so you get more storage space. |

| Higher Lifting Capacity | Reach trucks lift higher than regular forklifts. You use tall shelves better. | Example: Linde’s 5195 Reach Truck lifts up to 240" high. |

| Reach Capability | Forks can reach deep shelves without moving the truck close. | You can use double-deep racks and fit more pallets. |

Flexibility

Forklift booms make your forklift more useful. You can change the boom’s angle and length for different jobs. You can lift long rolls, heavy coils, or other shapes. You can pick from telescoping, pivoting, or fixed-length booms. You do not need many machines for different jobs. You can lift heavy or odd-shaped things on construction sites. You can move big stone slabs in shops. You can handle long pipes or pallets in warehouses. Forklift booms let your forklift do what a crane does. This makes work safer and faster.

You can reach things in small spaces and high places.

You can move loads regular forklifts cannot lift.

You can switch jobs without changing machines.

You can make work safer and use less manual labor.

Forklift booms help you do many jobs in different places. You get better reach, control, and safety. This saves you time and money.

Cost-Effectiveness

Forklift booms help you save money. You do not need to buy a crane. Forklift booms cost less and are easier to take care of. You need fewer workers, so you pay less for labor. Forklifts fit in small spaces, so you do not spend extra money moving equipment. Forklift booms are good for small or rare lifting jobs. You get more use from your forklift. Electric forklift booms save money on fuel and repairs. For example, electric forklifts may cost $1,500 to $2,000 each year. Gas forklifts may cost $10,000 to $15,000 each year. You can buy attachments like side shifters and jib booms. These help you work faster and safer. You spend less time and get less tired, so you save money and work better.

Note: Forklift booms help you save money with lower prices, less labor, and fewer repairs. You can plan your budget better and make your work easier.

Limitations and Comparison

Restrictions

You have to follow many safety rules when using a forklift boom. OSHA makes rules about where and how you can use these tools. Here are some important things you must do:

Always wear a safety harness and work on flat ground.

Never lift more than the weight limit. This stops the forklift from tipping over.

Stay far away from things like power lines.

Use a spotter and talk clearly with your team.

Check your forklift and boom before every use.

Only people with training and a certificate can use forklift booms.

The forklift and boom must have labels that show their total weight and how much they can lift.

You need the manufacturer’s permission before adding a boom.

These rules mean you cannot use forklift booms on bumpy or slippery ground. You also cannot use them with loads that are not balanced. If the operator is not trained, you cannot use the boom. Following these rules keeps everyone safe.

Forklift vs. Crane Attachments

You might wonder how a forklift boom is different from a crane attachment. Forklifts with booms can lift up to 8,000 pounds and reach about 12 feet high. If you make the boom longer, it cannot lift as much. Forklift booms do not move by themselves like cranes do. You move the load by driving the forklift and raising or lowering the mast. Cranes and telehandlers can lift much heavier things, sometimes up to 11,000 pounds, and reach over 30 feet high. Cranes work better on rough ground and can use many tools like hooks, scoops, and buckets. Cranes give you more reach and can do more jobs, especially outside or for heavy work.

Note: Forklift booms are good for inside or safe places. Cranes are better for big, heavy jobs and rough ground.

Forklift Boom vs. Standard Forks

A forklift boom lets you lift and move more types of loads than standard forks. Standard forks are best for pallets and boxes with regular shapes. If you need to lift long, big, or odd-shaped things, a forklift boom helps you do it safely and easily. You can use other hydraulic tools, like buckets or grapples, with a forklift boom. This makes your forklift more useful, but it also makes things harder and costs more money. You need extra training and must follow more safety rules.

| Aspect | Forklift Booms | Standard Forks |

|---|---|---|

| Load Versatility | Can lift loose, awkward, or big loads with special tools | Best for pallets or loads with regular shapes |

| Flexibility | Can change angles and lift many kinds of materials | Stays in one position, not much adjustment |

| Safety Requirements | Needs skilled workers and careful safety checks | Easier to use, not as many rules |

| Complexity | More parts and training needed | Simple and easy to use |

| Cost | Costs more to buy and take care of | Cheaper to buy and maintain |

You get more ways to use your forklift with attachments, but you also have to think about the extra safety steps and higher costs.

A fork truck lifting boom turns your forklift into a powerful lifting tool. You gain more reach and flexibility for tough jobs. Always focus on safety and proper training. Before using a boom, check your equipment and work area. Make sure the boom fits your forklift and never exceed weight limits.

Train operators on attachment use and hazards.

Inspect equipment and attachments before each lift.

Use fall protection and keep clear of power lines.

Stay alert and follow safe practices to protect yourself and your team.

FAQ

What is the difference between a forklift boom and a standard forklift fork?

A forklift boom lets you lift long, heavy, or odd-shaped loads. Standard forks work best for pallets and boxes. You use a boom for jobs that need extra reach or special lifting.

How do you attach a lifting boom to your forklift?

You slide the boom over the forks. You lock it with pins and secure chains around the carriage. Always check every part before you lift anything.

Can you use a forklift boom outdoors?

You can use a forklift boom outdoors if the ground is flat and stable. Telescopic booms work well on rough terrain. Always follow safety rules and check your equipment.

What safety gear do you need when using a forklift boom?

You need a hard hat, safety shoes, and a harness. You must check your forklift and boom before each use. Only trained operators should use the equipment.

How do you know the weight limit for your forklift boom?

Look at the rating tag on your forklift and boom. The manufacturer’s chart shows the safe lifting limit. Never lift more than the rated capacity.

English

English