AUGUST 22, 2025

Top Tips for Safely Operating Rough Terrain Forklifts on Uneven Ground

Imagine a worker operating rough terrain forklifts on a muddy site. He faces hidden dangers all the time. Tip-overs are the most deadly accidents. 42% of deaths happen from overturns. These often come from uneven ground or mistakes by the operator. Safe use of operating rough terrain forklifts needs good training and regular checks. You must also watch out for hazards. Getting tired makes injuries 37% more likely. So, staying awake and alert is important. Following safety tips helps stop accidents. It keeps everyone safe when operating rough terrain forklifts on tough ground.

Key Takeaways

Get certified and take refresher classes often to learn safe forklift use. Stay updated on the rules.

Check tires, brakes, steering, and attachments every day. This helps you find problems early. It keeps the forklift steady.

Look at the work site for slopes, soft ground, and things in the way before you drive. This helps you avoid accidents and tip-overs.

Follow load charts and keep loads balanced and low. This stops tipping and helps you control the forklift on rough ground.

Drive slowly and do not make sharp turns. Use stability features like frame leveling and outriggers to stay safe on uneven ground.

Training

Certification

You need more than skill to use a rough terrain forklift. You must follow the law and keep people safe. Every operator has to get certified before driving. Certification is not just a short lesson. It teaches about machine controls and what to do in emergencies. Here are the main things needed for certification:

Operators have to be at least 18 years old.

They must learn safety rules, forklift controls, and job dangers.

Each person must pass a test using the forklift. The test checks if you can drive, move loads, and handle emergencies.

Certification does not last forever. Operators must renew it every three years to follow OSHA rules.

Training also teaches about special problems. These include driving on bumpy ground, keeping loads balanced, and checking the forklift every day.

Tip: Companies should always make sure workers have current certification. This helps stop accidents and keeps everyone safe at work.

Refresher Courses

Even good operators need reminders sometimes. Refresher courses help everyone remember safety rules. OSHA says operators must take refresher training every three years. Sometimes, they need it sooner. Here is when refresher courses are needed:

| Condition for Refresher Training | Description |

|---|---|

| Mandatory Interval | Every 3 years for all forklift operators |

| Unsafe Operation | If someone uses the forklift in a risky way |

| Accident or Near-Miss | After any accident or close call |

| Deficient Evaluation | If a test shows unsafe driving |

| Different Forklift Type | When using a new kind of forklift |

| Changed Working Conditions | If the work area changes, like moving outside |

Training before using a rough terrain forklift is not just a rule. It is very important for safety. Getting certified and taking refresher courses helps everyone work safely and avoid harm.

Rough Terrain Forklifts: Inspection

Daily inspections keep rough terrain forklifts safe and steady on the job. Operators should check every part before starting work. This helps spot problems early and keeps everyone safe.

Tires and Wheels

Tires and wheels play a big role in forklift stability. Operators should look for flat spots, chunking, and tread wear. They need to check for heat cracks and uneven wear. If a tire is two inches shorter than when new, or if 60% of the tread is gone, it is time to replace it. Sidewall splits or damage also mean the tire is unsafe. For rough terrain, air-filled pneumatic tires work best. Operators should check tire pressure every day. Underinflated tires can make the forklift bounce and lose stability. Wheels need a look too. Check for cracks, damaged rims, and missing lug nuts. Tighten any loose nuts and replace missing ones. Always park the forklift on level ground and set the brakes before checking tires and wheels.

Tip: Use a tire depth gauge to make sure tread grooves are deeper than 5 mm (0.2 in.). Good tread helps with traction and stability.

Steering and Brakes

Steering and brakes help control the forklift and keep it stable. Operators should check the steering wheel and column for looseness. Worn gears or low steering fluid can make steering hard. Misaligned tires or worn steering parts can cause the forklift to drift or turn poorly. Brakes need a close look too. Worn pads, leaks, or broken parts can lead to brake failure. Operators should test the brakes before each shift. Good brakes and steering keep the forklift steady, even on rough ground.

Attachments

Attachments like forks, clamps, or buckets must be secure and in good shape. Operators should check for cracks, bent metal, or missing pins. They should also inspect the mast, lift chains, and hydraulic hoses for leaks or damage. All safety features, like seat belts and overhead guards, need to work right. These checks help the forklift keep its stability and protect the operator.

Note: Checking every part of the rough terrain forklift helps prevent accidents and keeps stability strong all day.

Site Assessment

Before using a rough terrain forklift on uneven ground, workers must check the site. Construction sites can have bumpy surfaces, slopes, soft dirt, and trash. These dangers can cause accidents if people ignore them. Looking at the site helps keep forklifts steady and workers safe.

Slopes

Slopes are found on many construction sites. Operators should check how steep the slope is before driving. Slopes over 15 degrees can make forklifts tip over. Here are some ways to handle slopes:

Go slow and be careful when driving up or down.

Follow the forklift’s grade rules to stop tipping.

Do not turn sharply on hills.

Stay away from ditches and holes near slopes.

Tip: Drivers should keep the load low and point uphill when going up a slope. This helps keep the forklift steady and easy to control.

Soft Ground

Soft or muddy ground can be risky for rough terrain forklifts. The ground might not hold the forklift’s weight. This can make the forklift tip or sink. Mud makes it hard to steer and stop. Operators should not use forklifts on soft ground unless they must. Forklifts with high clearance and deep-tread tires or four-wheel drive work best here. Drivers should check tires before starting, slow down on wet ground, and spread loads evenly. Construction sites can change fast, so staying alert is important for safety.

Note: Even with special features like frame leveling and wide wheelbases, how the driver acts is most important. Drivers should keep loads low, go slow, and look at the ground before moving.

Obstacles

Things like rocks, trash, and building materials can block the way and make forklifts unstable. Operators should walk the path first and move anything that could get in the way. Keeping the path clear helps stop accidents and keeps the forklift steady. On busy sites, new obstacles can show up fast, so checking often is needed.

| Common Obstacles | How to Handle Them |

|---|---|

| Rocks | Move or avoid |

| Debris | Clear before driving |

| Trenches | Mark and avoid |

| Equipment | Plan route around |

Checking the site helps everyone stay safe and keeps rough terrain forklifts steady on uneven ground.

Load Management

Load Charts

Operators need to check the forklift’s load chart before every job. The load chart shows how much weight the forklift can lift and how high it can go. It also lists important details like:

Model and serial number

Fuel type

Installed attachments

Tire size

Lifting capacities at different heights

Diagrams showing load center and lifting height

Maximum fork height

Rated load centers (horizontal and vertical)

Capacity changes with boom angle or extension

The load chart helps workers know the safe limits for loading. If the load is too heavy or too far from the mast, the forklift can tip over. Operators should always follow the chart for proper loading and never guess the weight.

Tip: Always check the load chart when using new attachments or working on a different jobsite.

Balancing

Keeping the forklift balanced is key for safe loading. Operators should follow these steps:

Never go over the forklift’s rated capacity.

Place the load close to the front wheels to keep the center of gravity low.

Put the heaviest part of the load toward the mast.

Carry loads as low as possible.

Accelerate slowly and avoid sharp turns.

Tilt the forks back a little to secure the load.

Lower the load before moving the forklift.

Use outriggers on soft ground and make sure they are fully extended.

Training helps operators learn these steps. When workers understand balance, they can handle loading on rough terrain with more confidence.

Height Limits

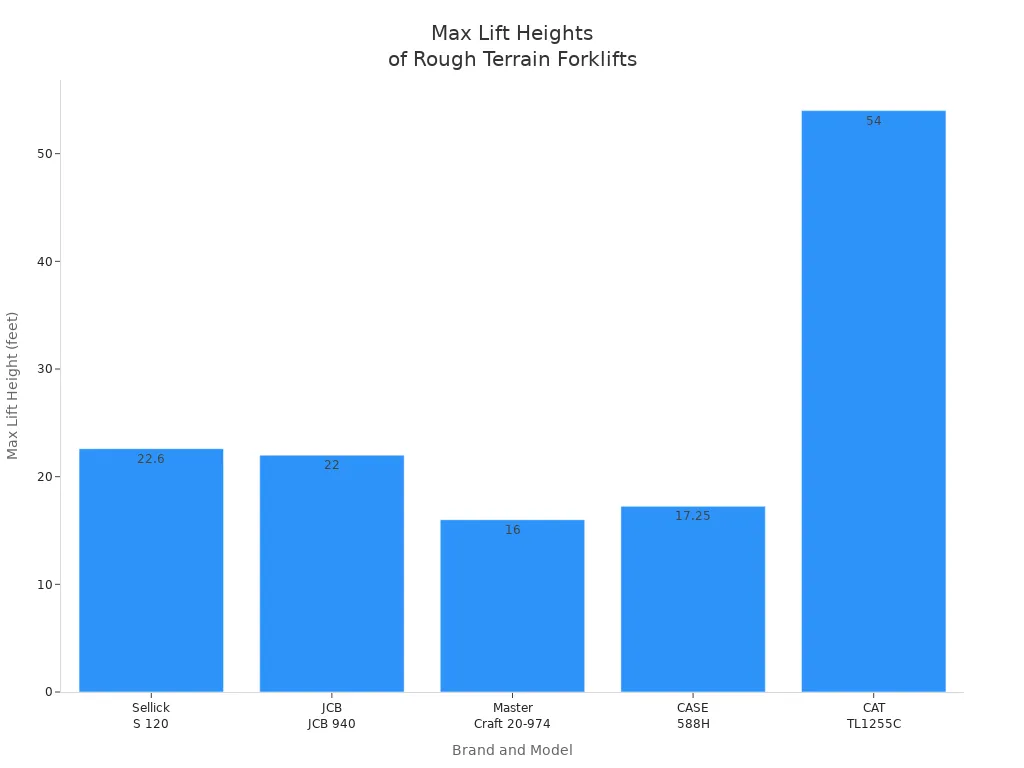

Rough terrain forklifts can lift loads very high, but height affects stability. Most models can safely lift between 16 and 54 feet, depending on the brand and type. Here’s a quick look at some popular models:

| Brand | Model | Max Lift Height (feet) |

|---|---|---|

| Sellick | S 120 | ~22.6 |

| JCB | JCB 940 | ~22 |

| Master Craft | 20-974 | ~16 |

| CASE | 588H | ~17.25 |

| CAT | TL1255C | ~54 |

Operators should remember that lifting higher lowers the forklift’s safe loading capacity. Telehandlers can reach even higher if they are stable and the operator is trained. Workers should always check the ground and keep loads low when possible.

Note: Lifting too high on uneven ground can cause tip-overs. Always follow the forklift’s height and loading limits.

Operating Rough Terrain Forklifts: Driving

Speed Control

Speed is important when using rough terrain forklifts on bumpy ground. OSHA does not give a set speed limit. Operators must pick a safe speed for each job. It is best to drive slow and change speed if needed. The ground, the load, and people nearby all matter. Mud, gravel, or uneven spots can make the forklift bounce or tip. Going too fast makes it easier to lose control. It also makes the forklift less steady. Operators should not start or stop quickly. Driving smooth and steady keeps the forklift balanced and safe.

Tip: Go slow and be careful. Moving at a safe speed helps stop accidents and keeps everyone safe at work.

Slope Maneuvering

Slopes are found on many building sites. Operators must use special steps to keep the forklift steady:

Go straight up or down the slope every time.

If you have a load and go uphill, drive forward with forks facing up.

If you go downhill with a load, drive backward and keep forks uphill.

If there is no load, back up the hill with forks pointed down.

Never turn while on a slope. Turning can make the forklift tip over.

Look at ramps for cracks, trash, or slippery spots before using them.

Use ramps with guardrails if you can.

Know how steep your forklift can go and do not carry too much.

Operators should drive slow and keep the load low. These steps help keep the forklift steady and easy to control, even on rough or steep ground.

Visibility

Seeing well is very important for safe forklift driving. Operators need to check that the path is clear of things and people. If the load blocks the view, drive backward to see better. Keep the forks low, about 4 to 6 inches above the ground. This helps you see and keeps the forklift steady. Clean windows and mirrors help you see more. If you cannot see well, ask a spotter to help guide you. Operators should always watch for new dangers and stay alert.

Note: Training and daily checks help drivers find problems early and keep everyone safe when using rough terrain forklifts.

Stability Features

Modern rough terrain forklifts have special features to help them stay steady. These machines work on rough ground, so extra support is important. These features help keep loads safe and protect workers. There are three main features that help a lot.

Frame Leveling

Frame leveling helps the forklift stay steady on bumpy ground. This system uses hydraulic cylinders to move the frame. The operator can make the forklift level, even if the ground is not flat. When the frame is level, the forklift holds its load better. This puts less stress on parts like the mast. It also lowers the chance of tipping over. Many brands, like AUSA and Manitou, have frame leveling as a standard or extra feature. Operators can lift loads with more confidence because the forklift stays balanced.

Tip: Use frame leveling before lifting on rough ground. It helps keep the load safe and makes the forklift more stable.

Outriggers

Outriggers are like extra legs for the forklift. Telehandlers use outriggers to stop the machine from tipping when the boom is out. These hydraulic supports make the forklift’s base wider. This makes it much harder for the forklift to tip over. Outriggers are very important when lifting heavy loads or working on slopes. They spread out the weight and help keep the forklift steady.

Outriggers give:

Extra support on soft or bumpy ground

Better balance when lifting high or heavy loads

More stability on sloped ground

Operators should always check that outriggers are all the way out and locked before lifting.

Stabilizers

Stabilizers work with other features to keep the forklift safe. Many new forklifts have electronic tilt and sway controls. Some have anti-tilt systems and load moment indicators. These systems watch for changes in balance and help stop tipping. Some forklifts have hill hold assist to stop rolling back on slopes. Others use load sensing valves to help the hydraulics work better as the load changes. Safety features like roll-over protection, seat belts, and strong axles also help keep the forklift steady.

Here is a list of common stability features on today’s rough terrain forklifts:

Four-wheel drive and deep-tread tires for grip

Strong axles and flexible suspension

Roll-over and falling object protection

Better brakes and operator presence systems

Cameras, sensors, and alarms for better awareness

All these features work together to keep the forklift steady, even on rough ground. Operators should learn how each system works and use them every time for the best safety.

Emergency Procedures

Tip-Overs

Tip-overs happen fast on rough terrain. Operators must know what to do if the forklift starts to tip. He should stay calm and think clearly. Holding the steering wheel tight helps keep control. He can brace his feet against the floor or sides of the forklift. Leaning away from the direction of the tip lowers the chance of being thrown out. He should use his arms to shield his head from impact or falling objects. Waiting until the forklift stops moving is important before trying to exit. Once the forklift is stable, he should call for help. Exiting slowly and carefully keeps him safe. After leaving the forklift, he must report the incident to his supervisor. These steps help prevent serious accidents and protect everyone nearby.

Recommended steps during a tip-over:

Stay calm and think clearly.

Hold the steering wheel firmly.

Brace feet against the floor or sides.

Lean away from the tip.

Shield head with arms.

Wait for the forklift to stop.

Call for help.

Exit slowly if safe.

Report the incident.

Tip: Practicing these steps can help operators react quickly and avoid injuries during accidents.

Mechanical Failures

Mechanical failures can happen at any time. He should stop the forklift right away if something feels wrong. Turning off the engine and setting the brakes keeps the forklift from moving. He must not try to fix the problem alone unless he is trained. Calling maintenance or a supervisor is the best choice. If the forklift breaks down on uneven ground, he should warn others and mark the area. This helps prevent more accidents. Checking the forklift before each shift lowers the risk of mechanical failures.

| Common Failures | What to Do |

|---|---|

| Brake problems | Stop and call for help |

| Steering issues | Turn off engine and report |

| Hydraulic leaks | Mark area and get maintenance |

Incident Reporting

Reporting accidents helps everyone learn and stay safe. He should tell his supervisor about any accident, tip-over, or mechanical failure. Giving details about what happened helps the team fix problems and prevent future accidents. Filling out an incident report is part of the job. He should include the time, place, and what caused the accident. Sharing this information helps improve safety for all workers.

Note: Quick and honest reporting leads to better training and fewer accidents in the future.

Shutdown

Parking

Operators should always park rough terrain forklifts with care, especially on uneven ground. They need to check the ground first. The surface should be solid and stable. Soft or sloped areas can cause the forklift to roll or tip. Operators should avoid parking in these spots unless they take extra steps. Before stopping, they should look for wires, trees, or other machines nearby. Parking slowly helps prevent sudden movements. Lowering all lift arms or extensions to the ground keeps the forklift steady. On any incline, wheel chocks help stop the machine from rolling. Operators should also engage the parking brake every time. After parking, they need to lock all security features. Placing signs or barriers around the forklift can warn others to stay away.

Tip: Always choose a safe, flat spot for parking. This simple step can prevent many accidents.

Securing

Securing the forklift is just as important as parking it. Operators should make sure the forks rest flat on the ground. This keeps the forklift from moving. They must turn off all controls and remove the key. Locking the cab or control panel stops anyone from using the forklift without permission. On rough or sloped ground, wheel chocks add extra safety. Operators should double-check that the parking brake is set. If the forklift sits near busy areas, signs or cones can help keep people and vehicles away.

Post-Use Checks

After shutting down, operators should inspect the forklift before leaving. They need to look for damage, leaks, or loose parts, especially on the mast and tires. Checking fluid levels—like engine oil, coolant, brake, and hydraulic fluids—keeps the forklift ready for the next use. Operators should test the brakes and listen for odd sounds. Tires need a close look for cuts, low pressure, or wear. Forks and attachments should be straight and secure. All safety devices, such as seat belts, horns, and lights, must work well. If operators find any problems, they should report them right away and not use the forklift until repairs are done.

Note: A quick post-use check can catch small issues before they become big problems. This habit keeps everyone safer on the job.

Driving rough terrain forklifts on bumpy ground is hard. Workers must use safety tips each day. Training helps them learn how to stay safe. Checking the forklift and the site stops accidents. Online classes and safety signs remind everyone about safety. Operators should wear safety gear and check their equipment. Using mirrors helps them see better. New forklifts have lithium-ion batteries and smart sensors. These features help make work safer. Staying awake and following rules keeps the site safe. Safety should always come first, every shift and every day.

FAQ

How often should operators inspect rough terrain forklifts?

Operators should check the forklift before every shift. They need to look at tires, brakes, steering, and attachments. A quick daily check helps catch problems early and keeps everyone safe.

What should someone do if a forklift starts to tip over?

He should stay in the seat, hold the steering wheel tight, and lean away from the tip. Jumping out is dangerous. Wait until the forklift stops moving, then exit carefully.

Do operators need special training for rough terrain forklifts?

Yes, operators must get certified for rough terrain forklifts. Training covers controls, safety rules, and how to handle uneven ground. Refresher courses help keep skills sharp.

What is the safest way to drive on a slope?

Keep the load low.

Drive straight up or down the slope.

Never turn on a slope.

Go slow and stay alert.

Tip: Always check the ground before moving on a slope.

English

English