September 23, 2025

Assessing Forklift Charging Methods

Choosing the best Forklift Charging method changes how work gets done each day and how much money is spent over time. Good batteries give more power, so forklifts can work longer before they need to charge again. Companies that use smart chargers often spend less money and have fewer breaks in work.

Intelligent charging systems can make batteries last up to 30% longer.

Alerts and remote checks help keep all forklifts working.

Every business should think about its work hours, space, and safety rules before picking a charging method.

Key Takeaways

Picking the best forklift charging method can help save money. It also makes work faster. Think about your work hours and space before you choose.

Smart charging systems can make batteries last up to 30% longer. They check battery health and pick the best charging times.

Opportunity charging lets forklifts charge during breaks. This cuts down on waiting and keeps work going well.

Regular maintenance and safety checks are very important. Check batteries and chargers every week to stop accidents and keep them working well.

Buying smart chargers may cost more at first. But they can save a lot of money on energy and new batteries later.

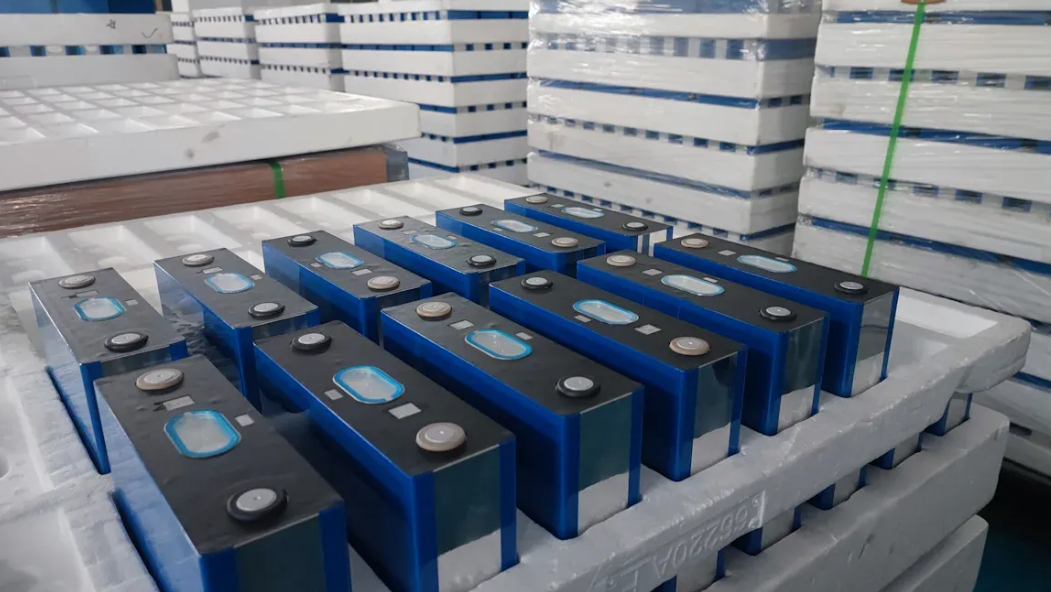

Forklift Charging Methods

Image Source: unsplash

Conventional Charging

Conventional charging works well for one shift. Workers plug in the battery after their shift ends. Charging takes about eight hours. The battery then needs eight more hours to cool down. This method makes gas, so air flow is important.

A normal charger fills the battery in eight hours.

Batteries must cool for eight hours after charging.

| Charging Method | Characteristics |

|---|---|

| Conventional | Best for one shift, needs 8 hours to charge, 8 hours to cool, and follows a daily routine. Makes gas during charging. |

Opportunity Charging

Opportunity charging lets workers charge forklifts during breaks. This keeps forklifts working longer without big stops. Lithium-ion batteries work well with this method and keep forklifts running. Lead-acid batteries can lose up to 40% of their life if charged this way.

| Battery Type | Impact on Lifespan | Impact on Productivity |

|---|---|---|

| Lithium-Ion | Small loss in life | Keeps forklifts working |

| Lead-Acid | Up to 40% less life | Takes time to swap |

Fast Forklift Battery Charging

Fast charging lets workers recharge batteries quickly during short breaks. This helps busy warehouses keep forklifts ready. Workers must follow safety rules. They should use good cables and keep battery covers open to let heat out. Overcharging can make heat and gas, so watching the battery is important.

| Safety Consideration | Description | Mitigation Strategy |

|---|---|---|

| Overcharging | Makes too much heat and gas, which can cause fires. | Follow charging rules and check battery levels. |

| Poor Ventilation | Gas can build up and cause explosions if air is bad. | Make sure air moves well in charging areas. |

| Physical Damage | Broken batteries can leak and cause problems. | Check batteries often and replace broken parts fast. |

Battery Swapping

Battery swapping means workers take out empty batteries and put in charged ones. This cuts down on waiting and is good for places that never stop. Companies need extra batteries and space to store them.

| Charging Method | Characteristics |

|---|---|

| Battery Swapping | Workers switch empty batteries for full ones, so there is less waiting. Good for nonstop work. Needs extra batteries. |

Smart charging systems help companies pick the best charging ways. These systems watch battery health and use. They help balance charging and make batteries last longer.

Comparing Forklift Charging

Efficiency and Downtime

Efficiency and downtime are important in warehouses. If a forklift battery stops working, work must pause. This can slow things down and cost more money. When work stops, workers may not have anything to do. Shipments might not go out on time. Lost work can cost $100 to $300 every hour. The cost depends on how busy the warehouse is.

Smart chargers help cut down on downtime. They charge batteries faster and keep them in good shape.

Traditional chargers are cheaper at first. But they might cause more downtime later.

Opportunity charging lets workers charge during breaks. This keeps forklifts working longer and avoids big stops.

Fast forklift battery charging gives a quick charge during short breaks. This is good for busy warehouses with little extra time.

Battery swapping lets workers change batteries fast. This works best in places that never stop working.

Tip: Check batteries often and use smart charging systems. This helps keep downtime low and work moving fast.

Cost and Investment

Picking a forklift charging method changes costs now and later. Each way has its own price and savings.

Traditional chargers cost less to buy. But they can cost more over time. They wear out batteries faster and use more power.

Smart chargers cost more at first. But they save money later. They charge better, use less energy, and help batteries last longer.

Opportunity charging and fast charging can make electric bills go up if not managed well. Smart systems help control these costs.

Battery swapping needs more batteries and storage space. This means spending more money at the start.

Knowing about each charging method helps companies choose the best one. Smart chargers use real-time data to charge only when needed. This helps save money and keeps forklifts working well.

Safety and Maintenance

Safety and maintenance matter for every charging method. Each system has its own risks and needs.

| Charging System Type | Maintenance Needs | Yearly Cost Estimate |

|---|---|---|

| Conventional Charging | Regular checks, cable care, cleaning, and repairs | Up to $400 per charger |

| Opportunity Charging | Like conventional, but electric costs can change | Up to $400 per charger |

| Fast Charging | More upkeep because of high use, repairs can cost more | Over $800 per charger |

| Battery Swapping | Check and fix equipment | N/A |

Safety tips for all charging methods:

Read the manual and follow all steps.

Use the right tools and charger settings.

Check batteries often for leaks or damage.

Common safety risks include:

Forklifts can tip over if batteries are not cared for.

People can get hurt if workflow changes are not safe.

Old parts can break and cause problems.

Heavy batteries can hurt people if not moved safely.

Charging can make gas that can catch fire, so air must move well.

Batteries have chemicals that can burn skin or eyes.

Note: Always wear gloves and goggles when working with batteries. Keep charging spots clean and let air flow well.

Operational Impact

The charging method changes how a warehouse works. Centralized charging is good when forklifts return to one place to charge. This fits shift work and planned breaks. Decentralized charging lets forklifts charge in different places. This helps when forklifts work all day and need to charge during short stops.

Opportunity charging helps workers charge during lunch or breaks.

Fast charging is good for busy places with no time for long stops.

Battery swapping keeps forklifts moving in places that never stop.

Best practices are to use chargers that match the battery type and size. Companies should check batteries and chargers often to find problems early.

Forklift Charging Stations

Image Source: unsplash

Space and Infrastructure

A good forklift charging station keeps work safe and easy. Companies need enough space for all batteries and tools. The electrical system must give power to every charger. Charging batteries can make hydrogen gas, so air must move well. Putting stations in open places helps stop gas from building up.

Workers need space to move and reach batteries easily.

A good setup stops crowding and makes fixing things faster.

OSHA rules say to use no smoking signs, fire safety, and emergency tools.

Safety Measures

Safety is very important at every forklift charging station. Floors that resist acid help stop damage from spills. First-aid kits and spill kits should be close by. Workers must keep safety papers and checklists up to date.

Charging areas need good air flow to get rid of hydrogen gas.

Emergency eyewash and fire safety must be nearby.

Workers should wear gloves, goggles, and other safety gear.

Regular checks find leaks, bad cables, or other dangers.

Tip: Companies should teach all workers safe charging steps and what to do in emergencies.

Smart Charging Systems

Smart charging systems help batteries last longer and cost less. These systems use a battery management system to watch voltage and temperature. Real-time checks show how batteries are used and their health.

Smart systems stop overcharging and undercharging, so batteries last longer.

They change charging times to match how forklifts are used.

Good charger management saves money by charging at the best times.

Fast forklift battery charging works best with smart systems that keep batteries safe.

Forklift charging stations with smart tech help companies save money and keep forklifts working longer.

Selection Factors

Budget and Cost

Picking a forklift charging method starts with knowing your budget. Companies need to match the charger to the battery’s amp hour rating. It should be within 10% so batteries do not get too much or too little charge. The charger’s output voltage must be the same as the battery’s voltage. This keeps batteries safe and working well.

The charger must have the right input voltage for the building.

Businesses pick single-phase or three-phase input. This depends on how much power is needed.

Chargers with an equalize setting help batteries last longer.

A company should look at all costs. This means thinking about replacement parts, warranty, and how long equipment lasts. They also need to think about how fast the charger works and if extra batteries are needed.

How well things work matters. Companies can use overall equipment effectiveness (OEE) to see how charge time changes costs and if more batteries are needed.

Downtime and Productivity

Downtime slows work in every warehouse. When a forklift stops to charge, work gets slower.

Even short downtime can cause problems for the whole warehouse. The biggest cost of forklift downtime is lost work.

Opportunity charging helps forklifts keep working during breaks.

Charging during breaks or between shifts is a good way to keep forklifts running with less downtime.

Fast charging and battery swapping cut waiting time.

Every minute spent charging forklifts can cost a lot of money over time. Powering your forklift means work stops for a while.

A company does better when forklifts run at full speed.

The faster you get forklifts working again, the more your team and company will gain.

Checking charging needs and system performance often helps keep downtime low.

Business Size and Usage

Business size and how much forklifts are used change which charging method is best. The table below shows which method fits each type of business.

| Charging Method | Best Suited For | Key Characteristics |

|---|---|---|

| Conventional Charging Systems | Smaller businesses with lower usage | Long charge cycles, longest battery life, best for low use. |

| Opportunity Charging Systems | Larger businesses with higher usage | Short charges during breaks, more uptime, best for lithium-ion batteries. |

Smaller companies with fewer forklifts often use conventional charging. This helps batteries last longer. Bigger companies with busy warehouses use opportunity charging. This keeps forklifts working and fits well with new battery technology.

Compliance and Safety

Safety and rules protect workers and equipment. Companies must follow local and national laws. The table below lists important safety rules.

| Requirement | Description |

|---|---|

| Ventilation | Make sure air moves well to stop dangerous gases from building up. |

| Fire Protection | Put fire safety tools like fire extinguishers in the charging area. |

| Emergency Eyewash and Shower | Have an eyewash station and shower close by for chemical splashes. |

| Electrical Safety | Make sure electrical work follows the National Electrical Code for safe connections. |

| Training | Teach workers how to handle batteries and what to do in emergencies. |

| Ignition Sources | Keep flames, sparks, and other fire risks away from charging areas. |

| Maintenance | Check and fix charging equipment often for safety and good work. |

| Signage | Put up clear signs showing where the charging station is and any dangers. |

| Personal Protective Equipment (PPE) | Make sure workers wear gloves and goggles when handling batteries. |

| Spill Containment | Use spill kits and other tools to clean up acid leaks or spills. |

Companies should check charging stations often. They need to train workers and use safety gear. Good safety steps help protect people and keep batteries working well.

Tip: Companies should check charging needs and system performance every year. This helps them pick the best method and keep forklifts running safely.

Decision Guide

Assess Needs

Each company should first look at how it works. They need to know how many shifts they have. They should see what kind of work is done. It is important to know how often forklifts are used. Managers can ask some questions to help:

How many forklifts are used at once?

How long does each forklift run before charging?

Does the warehouse have one shift or more?

What is the return on investment for battery systems now?

Companies also need to check if their electrical system can handle new chargers. The charging area must have enough space for safe movement and future needs. Safety rules like good airflow and acid-proof floors keep workers and equipment safe.

Compare Methods

Once needs are clear, companies should look at different charging methods. Each method works best for certain jobs. These steps help compare them:

Make sure the battery type fits the charger.

Check that the charger voltage matches the battery.

Decide how much time there is for charging.

Follow the maker’s charging rules.

Think about how often forklifts are used.

Look at the building’s electrical system.

Plan for enough space and safety in the charging area.

A table can help show the choices:

| Method | Best For | Key Considerations |

|---|---|---|

| Conventional | Single-shift, low use | Long charge, longest life |

| Opportunity | Multi-shift, high use | Short charges, more uptime |

| Fast Charging | High demand, busy ops | Quick charge, more upkeep |

| Battery Swapping | 24/7 operations | Extra batteries, more space |

Plan Implementation

The last step is to plan the setup. Companies should pick a spot for the battery room that is easy to reach. There must be enough space for trucks and batteries. The area should follow safety rules, like good airflow, plumbing, and storage for safety gear. The floor should not get damaged by acid and should stay flat to protect equipment.

Tip: Getting help from a material handling expert is smart. Experts can give advice about safety, equipment, and future needs.

Picking the best forklift charging method makes work safer and easier. Putting charging stations in smart spots helps save money and keeps forklifts working longer. Charging during breaks can also help forklifts stay ready. Checking the system often finds problems early and keeps things running well. Skipping maintenance or not following charging times can cause trouble. New chargers work fast, help batteries last longer, and use less power. Companies should look at the decision guide and talk to experts for the best plan.

Training workers often and checking equipment keeps everyone safe and forklifts working.

| Benefit | Description |

|---|---|

| Reduced Downtime | Fast charging helps forklifts get back to work. |

| Enhanced Battery Life | Smart systems help batteries last longer. |

| Lower Energy Use | Good chargers use less electricity. |

FAQ

What is the safest way to charge a forklift battery?

Workers need to follow the maker’s steps. They should wear gloves and goggles. Charging stations must have good air flow. Checking batteries often stops leaks and damage. Safety gear and emergency kits should be close by.

How often should companies check forklift batteries and chargers?

Companies should look at batteries and chargers every week. They need to check for leaks, broken cables, and worn parts. Regular checks help stop accidents and keep forklifts working.

Can forklift battery opportunity charging harm battery life?

Opportunity charging works best with lithium-ion batteries. Lead-acid batteries can lose up to 40% of their life if charged this way. Companies should pick the right battery for their charging method.

What should a charging station include for safety?

A charging station needs floors that resist acid and good air flow. It should have fire extinguishers and eyewash stations. Workers must keep the area clean and use safety signs. Only trained workers should handle batteries.

How does smart charging help companies save money?

Smart charging systems watch battery health and use. They stop overcharging and undercharging. These systems help batteries last longer and lower energy costs. Companies spend less on fixing and replacing batteries.

English

English