AUGUST 28, 2025

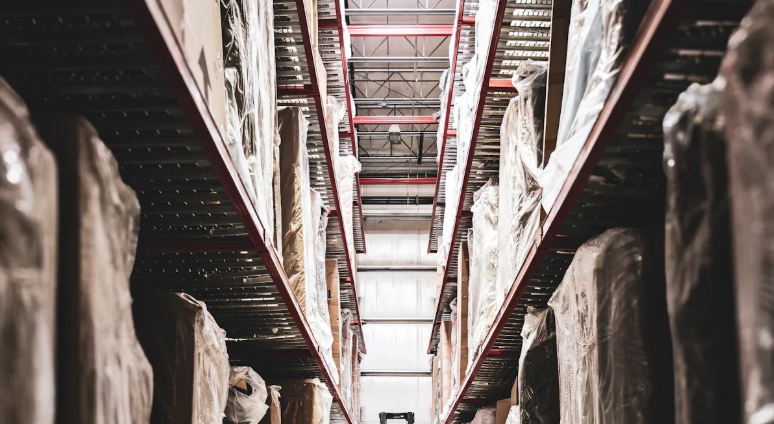

How to Efficiently Stack Wide Loads in Narrow Aisles

Stacking wide loads in narrow aisles is challenging and requires careful planning. You encounter numerous issues each day:

Safety problems increase because small spaces make crashes more likely.

Limited space restricts your movement, making it harder to maneuver items.

Using equipment becomes difficult, as tight turns and small areas slow you down.

To efficiently stack loads and maintain safety in your work environment, you need specialized equipment and a solid plan.

Key Takeaways

Pick the best equipment for stacking wide loads. Use special forklifts and stackers that match your warehouse. This helps keep things safe and makes work faster.

Use good stacking methods. Try staggered stacking and interlocking patterns. These ways make stacks steady and stop loads from moving.

Make your warehouse layout better. Build narrow aisles and use vertical storage systems. This saves space and makes it easier to reach items.

Always follow safety rules when moving loads. Wear protective gear every time. Check if the load is balanced. Drive slowly to avoid accidents.

Take care of your equipment often. Check forklifts and storage systems many times. This keeps them working safely and well.

Efficiently Stack Wide Loads

Wide Loads Equipment

Picking the right equipment is the first thing you should do. The machines you use must fit your warehouse and handle wide loads. You do not want to waste space. Many experts say you should use special forklifts and stackers. The table below lists some common equipment and what they do:

| Equipment Type | Features |

|---|---|

| Order Pickers | Great for getting items from high racks. |

| Pallet Jacks | Good for moving things on the ground and picking up from the floor. |

| End-control Riders | Made for moving sideways and picking up from the ground. |

| Reach Trucks | Used for stacking in narrow aisles. |

| Stand-up Rider Forklift | Works in tight aisles, reaches over 23 feet, and can go in and out of trucks. |

| 3-Wheel Electric Forklift | Works in tight aisles, lifts up to 23 feet, and carries up to 4000 lbs. |

| Multidirectional Reach Truck | Has special wheels for moving sideways, good for big, wide loads. |

| Furniture Order Picker | Lifts big items up to 366 inches, helps in furniture warehouses. |

When you pick equipment, think about how easy it is to move and how much it can carry. The table below shows two popular choices for wide loads in small spaces:

| Equipment Type | Maneuverability | Load Capacity |

|---|---|---|

| Multi Directional Forklifts | Very easy to move in any direction | Good for many types of loads |

| Side Loaders | Moves forward and sideways only | Great for long loads |

New warehouse machines make stacking in narrow aisles easier. For example, new wide straddle stackers can handle many materials and help you use more space. These stackers can lower their forks to the ground. This helps with closed-base pallets and lets you stack higher. Some can reach over 30 feet and lift heavier loads than before. Better visibility, like laser lines for fork placement, helps stop damage and makes work faster.

Tip: Buying special equipment for wide loads can cost a lot. Very Narrow Aisle (VNA) lift trucks are more expensive and work best in certain layouts. Check what your warehouse needs before you buy.

To keep your machines safe and working well, do these things:

Look at racks, car lifts, and storage gear often to stop problems.

Check anchors, oil the lifts, and test racks for weight.

Follow ANSI MH16.1 rules for straightness and anchoring.

Check more often if you lift heavy or special vehicles.

Get a third-party check every year to follow rules and avoid problems.

Stacking Techniques

You can stack loads better by using the right methods for your warehouse. Use a multidirectional reach truck if your loads are wider than six feet. This machine lets you use smaller aisles and still move big items. Always make sure your truck can lift the weight you need. Some trucks can lift up to 4,500 lbs.

Here are some easy ways to stack loads well:

Try staggered stacking to make a strong base and stop shifting.

Stack higher if your space allows to use more room.

Put each load in the middle of the forks and make sure the forks are all the way under before lifting.

For soft or bendy things, add extra support so they do not sag.

Pick your stacking style based on the load and packaging. Same-size boxes work with column stacking. Mixed sizes need different patterns.

Put heavy things on the bottom and do not make stacks top-heavy.

Use interlocking patterns for breakable items to stop them from moving.

Wrap stacks with stretch wrap, straps, or slip sheets to keep them steady.

Note: Your warehouse layout changes how you stack. A good layout helps you stack loads, move machines safely, and use all your space.

A smart layout also stops wasted space. Very narrow aisle trucks can work in aisles as small as 5.5 feet. This can give you up to 50% more storage. Better visibility, like wide mast openings and cameras, helps you see and stack safely.

When you stack wide loads well, you lower accident risks and use your warehouse better. Always match your stacking method to your load, packaging, and warehouse layout.

Narrow Aisles & Efficiency

Aisle Widths

You need to know the right aisle width. This keeps forklift efficiency high. It also helps you avoid accidents. The smallest aisle width depends on your equipment. It also depends on the size of your loads. Use this easy formula:

Minimum Aisle Width = Right-angle stack + Load length + 12 inches clearance

For example, your forklift has a head length of 76 inches. You use 48-inch pallets. Add 12 inches for turning. You get 136 inches. If your pallets hang over, add 3 inches to each side. Your total minimum aisle width is 142 inches. Always check the right-angle stacking width for your forklift. This tells you how much space you need to turn. It also helps you reach pallets safely.

OSHA says aisles should be at least 36 inches wider than your forklift. Most warehouses use aisles between 11 and 13 feet. This is for sit-down counterbalanced forklifts. You must follow these rules. This keeps your workspace safe and efficient.

Tip: Figure out your minimum aisle width before you change your layout. This step helps you avoid expensive mistakes. It keeps forklift efficiency high.

Space Optimization

You can use smart racking systems and vertical storage. This helps you save space and work better. Very Narrow Aisle (VNA) racking systems use every inch of your warehouse. These systems give you more pick faces and pallet spots. This means you store more items in less space. The table below shows how VNA racking helps your warehouse:

| Benefit | Description |

|---|---|

| Increased Pick Faces | More pick faces from vertical storage |

| Increased Pallet Positions | More pallet positions for better storage space |

| Greater Space Utilization | Less aisle space, more room for inventory |

| Increased Productivity | Faster access to goods, higher productivity |

| Real Estate Savings | Less floor space needed, lower costs |

| Improved Selectivity | Easier to find and pick SKUs |

| Decreased Cost per Sq Ft | Lower storage costs |

| Reduced Risk of Damage | Less chance of rack damage |

| Easy Implementation | Simple to set up |

| Safety Improvements | Less debris, safer environment |

Narrow aisle forklifts help your warehouse work better. These machines move easily in small spaces. They reach high shelves. You can use vertical storage to double or triple your warehouse space. Narrow aisle forklifts have advanced steering. They can move in many directions. You get better control and stability. This keeps forklift efficiency high. These features help you lift heavy loads. They also lower accident risks.

Space optimization also helps you move inventory faster. You spend less time walking between racks. You pick and process orders quicker. Using vertical storage and narrow aisles can increase your storage by up to 85%. You save space. You work faster. You keep forklift efficiency strong.

Note: Always check fire safety rules when you design your racks. Leave enough space for sprinklers and firefighting tools. Use materials that meet safety standards.

You can get top efficiency by using narrow aisles, vertical storage, and the right forklifts. This helps you save space, work faster, and keep your warehouse safe.

Safety Considerations

Safe Handling

You must follow safety steps when moving wide loads in narrow aisles. These steps help stop accidents and keep your team safe. The table below lists important safe handling steps from safety groups:

| Safety Procedure | Description |

|---|---|

| Safety Equipment | Make sure your forklift has mirrors, horns, and strobe lights. |

| Load Management | Distribute and secure the load to prevent tipping. |

| Operator Awareness | Stay alert and keep a clear view of the aisle ahead. |

| Speed Control | Drive at a safe speed and allow extra time for turns and stops. |

| Emergency Procedures | Know what to do in case of an emergency or incident. |

Always wear personal protective equipment like a safety harness. Keep the forklift forks low when you move in tight spaces. Check the load balance often and test the brakes before you start. Make sure no one stands close to the forklift or the load while you work.

Training is very important for safe use. Narrow-aisle forklift training teaches you how to move safely in small spaces. These classes have lessons, written tests, and hands-on practice. You learn about safety rules, load handling, and what to do in emergencies.

Tip: If you cannot see past a load, drive backward or use mirrors and spotters. This helps stop accidents and keeps everyone safe.

Load Stability

Load stability is very important when stacking wide loads. You must put each load in the center of the forks and make sure the forks are all the way under the load. This stops tipping and slipping. The table below shows why these steps are important:

| Guideline | Purpose |

|---|---|

| Center the Load | Keeps the load balanced and stable. |

| Position Forks Properly | Prevents the load from slipping or falling. |

If the weight is not even, the load can tip or fall, especially in narrow aisles. Using the right equipment for your space helps you avoid problems. Always move at a safe speed so you stay in control. Plan your routes to make travel shorter and lower accident risks. When you handle each load with care, you keep your team and your inventory safe.

You can work faster in narrow aisles with multidirectional forklifts. These forklifts let you stack wide loads easily. You do not need to turn much. Automation helps you track inventory and save money on workers. Safe storage systems help stop accidents. They keep heavy machines safe. Using space well helps you get more work done. It also helps you serve customers better. Many companies get their money back in 6 to 18 months. This happens after they train workers and buy new equipment. Look at your warehouse setup now. Start using these ideas for safer and smarter stacking.

FAQ

What equipment works best for wide loads in narrow aisles?

You should use side loaders, multidirectional forklifts, or VNA trucks. These machines move easily in tight spaces. They help you lift and stack wide loads safely.

How do you keep wide loads stable when stacking?

Always center the load on the forks. Make sure the forks go all the way under the load. Use straps or stretch wrap for extra support. This keeps your stacks safe.

Can you increase storage without making aisles wider?

Yes. Use vertical storage racks. Choose narrow aisle forklifts. These changes let you store more items in the same space. You do not need to widen your aisles.

What safety steps should you follow in narrow aisles?

Wear safety gear.

Drive slowly.

Use mirrors and spotters.

Check your load before moving.

Keep aisles clear.

These steps help you avoid accidents and keep your team safe.

English

English