AUGUST 26, 2025

What Is a Forklift? History and Uses

A forklift is a strong machine. It lifts and moves heavy things easily. Workers use forklifts in warehouses, construction sites, and factories. They help move items fast and safely. The forklift market is growing a lot around the world. Its value may reach over $79 billion in 2024. Companies in Asia Pacific, Europe, and North America use forklifts every day. They need them for jobs in retail, manufacturing, and construction.

What Is a Forklift

A forklift is a strong vehicle made to lift heavy things. It has a square frame and an open cabin for the driver. Two metal forks stick out from the front. These forks slide under pallets and other loads. The forklift lifts them straight up. Forklifts cannot move their forks out or to the side like telehandlers. This means they cannot reach far, but they can lift more weight. This also makes them safer to use. Forklift drivers need special training and a certificate. They learn how to balance loads and drive in small spaces. They also learn to use the forklift safely. Forklifts are different from other machines because they lift heavy things up and down very well. Many companies use forklifts inside buildings. Electric forklifts are popular because they do not make pollution. Forklifts are still very important in warehouses, factories, and building sites.

Tip: Forklifts stay steady with a counterbalance system. A heavy weight at the back keeps the forklift from tipping over.

Forklifts use hydraulics to lift and lower loads smoothly.

Safety systems warn about too much weight and help keep balance.

Some forklifts can lift up to 100,000 pounds, which is much more than regular ones.

Main Parts

All forklifts have main parts that work together for safety and good use. The table below lists the most important parts and what they do:

| Component Category | Main Components | Role in Operation |

|---|---|---|

| Chassis | Engine or battery, operator cab, counterweight, wheels | Gives the forklift its shape, power, place for the driver, balance, and lets it move. |

| Operator Compartment | Steering wheel, pedals, levers, gauges, safety features | Lets the driver steer, lift, and keep the forklift safe. |

| Mast Components | Mast, lift cylinder, load backrest, forks, carriage | Helps lift, lower, tilt, and hold loads. |

| Hydraulic System | Hydraulic lift cylinders, tilt cylinders | Makes the mast and forks go up, down, or tilt. |

| Power Source | Engine (propane, gasoline, diesel) or battery | Gives energy to move and work the forklift. |

| Counterweight | Heavy weight at rear of forklift | Keeps the forklift balanced so it does not tip. |

| Tires | Pneumatic tires (air-filled), cushion tires (solid rubber) | Give grip and balance for inside or outside use. |

| Drive and Steer Axles | Drive wheels (front), steer wheels (rear) | Drive wheels move the forklift; steer wheels turn and help balance. |

The driver’s area has a steering wheel, seatbelt, pedals, and levers. These controls help the driver move, lift, and tilt loads. They also help check how the forklift is working. An overhead guard keeps the driver safe from things that might fall. The hydraulic system is under the floor and makes the forklift lift and tilt. The counterweight at the back helps keep the forklift steady when lifting heavy things. Forklift tires are different for each place. Cushion tires are best for inside. Pneumatic tires work better outside on rough ground.

Types

There are many kinds of forklifts. Each one is made for a special job or place. The table below shows the most common types and what they do:

| Forklift Class | Power Source | Tire Type | Key Features / Design | Typical Use / Environment |

|---|---|---|---|---|

| Class I – Electric Motor Rider Trucks | Battery | Cushion | Quiet, zero emissions, sit-down or stand-up | Indoor warehouses, air quality sensitive areas |

| Class II – Electric Motor Narrow Aisle Trucks | Battery | Cushion | Narrow aisle design, articulated masts | Tight warehouse aisles |

| Class III – Electric Motor Hand Trucks | Battery | N/A | Pedestrian operated, manual movement | Short distance pallet movement indoors |

| Class IV – Internal Combustion Engine with Cushion Tires | Gas or Diesel | Cushion | For smooth surfaces, gas/diesel powered | Indoor/outdoor, low clearance areas |

| Class V – Internal Combustion Engine with Pneumatic Tires | Gas or Diesel | Pneumatic | Shock absorption, rough terrain capable | Indoor/outdoor, uneven surfaces |

| Class VI – Electric and Internal Combustion Engine Tractors | Battery, Gas, Diesel | N/A | Towing heavy loads, not lifting | Indoor and outdoor, warehouses, airports |

Counterbalance forklifts have a heavy weight at the back and forks in front. They work well in warehouses and loading docks. Electric motor rider trucks are quiet and do not make smoke, so they are good for inside. Narrow aisle trucks fit into small spaces and crowded storage areas. Reach trucks can stretch their forks to get things from high shelves. Side loaders carry long or big items in narrow spaces. Telehandlers are like forklifts and cranes together. They can reach over 50 feet high for building and farming. Rough terrain forklifts have big tires for bumpy ground. Pallet jacks and walkie stackers move pallets a short way in small warehouses.

| Forklift Type | Typical Load Capacity Range (lbs) | Typical Lifting Height |

|---|---|---|

| Electric 3-Wheelers | 3,000 - 5,000 | 10-20 feet |

| Electric 4-Wheelers | 3,000 - 12,000 | 10-20 feet |

| Internal Combustion Sit-Down Counterbalance | 3,000 - 158,500 | 10-20 feet |

| Rough Terrain Forklifts | 5,500 - 35,500 | 10-20 feet |

| Reach Truck | N/A | Up to 30 feet |

| Stacker | N/A | 10-15 feet |

| Telehandler | N/A | Over 50 feet |

Note: Today’s forklifts come in many types for different jobs. Companies pick the right one by looking at the load, how high it must lift, and where it will be used.

Forklift History

Early Material Handling

The story of the forklift starts with simple tools. Long ago, workers moved heavy things by hand or with ropes. They also used wooden carts to help. These ways were slow and took a lot of effort. In the late 1800s, inventors made new tools to help workers. The sack truck was one of the first. It had two handles and a long back. Its curved tines helped lift heavy things. Workers used it to carry big objects. People now think the sack truck was the first forklift.

By 1867, inventors made the portable elevator. It had an upright frame and a hand crank. It looked like a forklift mast. These new tools made lifting safer and quicker. Factories and warehouses started using them more. The first fork trucks from this time changed how goods were moved. They helped start the forklift timeline.

Industrial Revolution

The Industrial Revolution changed how people moved things. Factories got bigger and needed better tools. People began using machines instead of just people power. In 1804, the British Navy used steam-powered conveyor belts. This was the start of machine material handling.

Here is how the Industrial Revolution helped forklifts:

Steam cranes and hoists showed up in the 1800s. They lifted heavy things and made work easier.

The British Navy used conveyor belts for supplies. This was the first step to automated systems.

In 1913, Henry Ford made the assembly line. It made moving things faster and more organized.

World War II brought more changes. Factories used pallets and forklifts together. Synthetic rubber made conveyor belts stronger.

Machines made work safer and less hard. These changes led to modern forklifts and robots.

Factories and warehouses became safer and worked better. The forklift’s history shows how each new tool built on the last. The first fork trucks from this time helped make today’s machines.

First Forklift Invented

The first forklift was a big step in history. Early machines did not look like today’s forklifts. The table below lists the main inventions and what they did:

| Time Period | Inventor / Company | Invention / Model | Key Features |

|---|---|---|---|

| Mid-1800s | Unknown | Sack Truck | Two handles, long back, base for balance, hand crank lifting up to 5 feet, curved tines. |

| 1867 | Unknown | Portable Elevator | Upright frame, hand-cranked lift, similar to a forklift mast. |

| 1906 | Pennsylvania Railroad | Battery-propelled Bag Cart | Battery-powered, helped move heavy bags, first industrial truck. |

| 1917 | Eugene Clark / Clark Equipment Company | Clark Tructractor | First seated, counterbalanced, internal combustion-powered truck; used flatbed, no forks. |

| 1922 | Clark Equipment Company | Truclift | Used hydraulics to lift loads, improved forklift technology. |

The first forklift did not have forks. The Clark Tructractor from 1917 had a flatbed. It was the first seated, counterbalanced truck. This invention helped people use machines instead of just hands. In 1923, Yale made the first electric forklifts with forks and a mast. This model could stack things and looked like forklifts today.

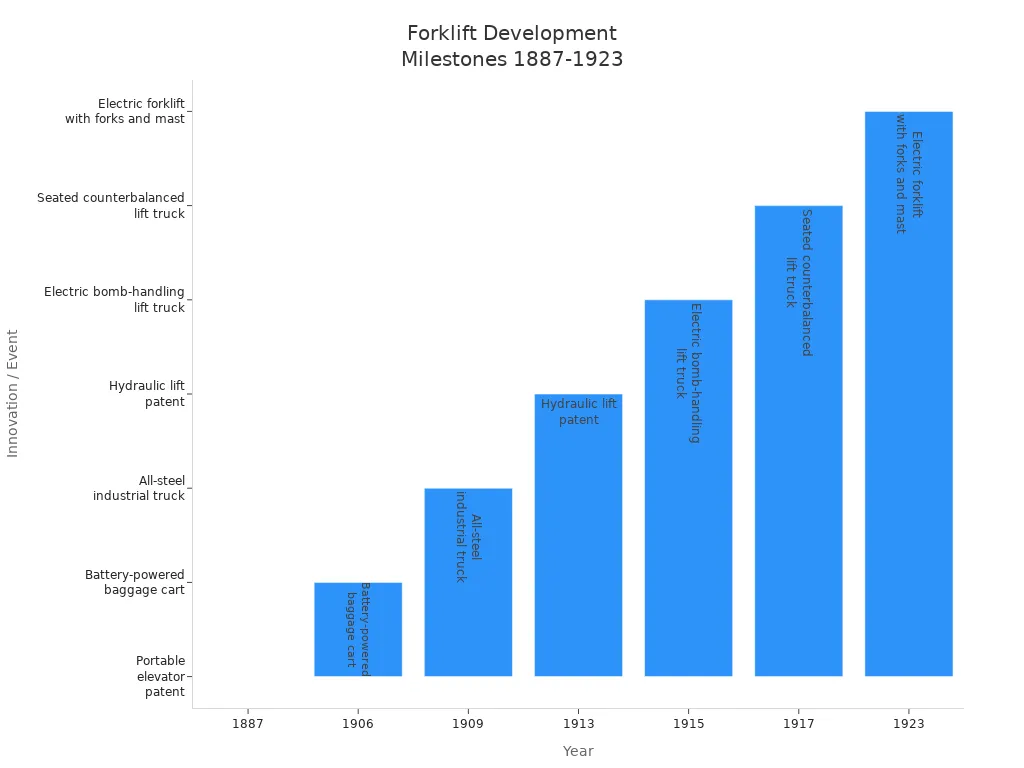

The forklift timeline has many important events. The chart below shows big moments from 1887 to 1923:

The first fork trucks from the early 1900s changed factories. The first forklift made warehouses work better. Companies like Clark and Yale led the way. Their ideas helped forklifts become safer and faster.

Note: The first forklift used new things like hydraulics and battery power. These features are still used in forklifts today.

World War I Impact

World War I made factories and warehouses change a lot. Many workers left to fight in the war. Companies did not have enough people to move heavy things. They started using machines to help with the work.

Factories used more powered tractors and lift trucks. These machines did jobs that many people used to do.

Clark in the United States made new powered trucks during the war. These trucks moved supplies faster and kept workers safer.

In the United Kingdom, Ransomes, Sims & Jefferies built special equipment for moving materials. This helped meet the needs of the war.

Factories had to store more goods in small spaces. They started stacking things higher than before. This led to new high-lift platform trucks.

The war made inventors work on better forklift designs. Forklifts got stronger and worked better. They became very important in factories. After the war, companies kept using forklifts. These machines saved time and made jobs safer.

Note: World War I made people want better storage and faster ways to move things. Forklifts improved a lot because of these changes. The first forklift models got better because of the war.

History of the Forklift: Key Innovations

Two Metal Forks and Mast

The first forklifts changed how companies moved heavy things. Early machines had flat platforms for lifting. Engineers later added two metal forks and a tall mast. The forks slide under pallets and lift them up. The mast holds the forks and helps them move safely. This new design made stacking goods easier and safer. Workers could lift items higher and fit them in small spaces. The mast helps control loads when lowering them. Forklift technology got better after this change. Factories and warehouses became faster and safer.

Tip: Two forks and a mast are still used today. Most forklifts use this setup to move pallets and other things.

Battery Power

Battery power made forklifts much better. Old forklifts used gasoline or diesel engines. These engines made loud noise and dirty exhaust. Electric forklifts use batteries instead. This makes them safer and better for inside work.

Lithium batteries stop spills and need less care, which matches OSHA rules.

Workers do not need special rooms to charge batteries, so places are safer.

Lithium batteries last longer and are easier to recycle, which helps EPA rules.

Fast charging and steady power mean less waiting and fewer problems.

Electric forklifts meet MHI and ANSI rules for good work.

Electric forklifts help drivers see better and avoid crashes. They do not use fuel, so there is no fire risk. Less noise helps drivers hear warnings. No exhaust means clean air inside and no carbon monoxide danger. New batteries charge fast and last longer, so work is quicker. Regenerative braking saves energy. Small designs and tight turns make forklifts safer in small areas. Lift height sensors help with safety and accuracy.

Battery power keeps making forklifts better. Companies pick electric models for clean, quiet, and safe work.

Hydraulic Systems

Hydraulic systems made forklifts stronger and easier to use. These systems use fluid to make strong lifting power. The pump sends fluid to valves and cylinders. Pressure in the cylinders lifts the forks and the load.

Hydraulic systems use Pascal’s Law. If you put 1,000 psi on a 10-inch cylinder, it can lift 10,000 pounds. This lets forklifts lift heavy things easily. Hydraulics help drivers control lifting and lowering. Relief valves stop too much pressure and keep things safe. The hydraulic system design decides how much weight a forklift can lift.

Hydraulics made forklifts work better. Drivers can lift pallets and loads quickly and safely. Hydraulic systems help forklifts do more in busy places like warehouses and factories.

Standardization

Standardization changed how companies use and build forklifts. Before rules, every warehouse used different equipment. This made things confusing and caused more accidents. Over time, safety groups and governments made new rules. These rules help keep forklift work safe and efficient. Now, companies everywhere follow the same safety steps.

A big change was making operator training a rule. Every forklift driver must finish special training and get certified. The training has classroom lessons and hands-on practice. Trained drivers know how to move loads and drive safely. They also learn how to avoid accidents. Companies must keep records of all training, checks, and accidents. This helps them track safety and get better over time.

Regular maintenance is another important rule. Forklifts need to be checked and fixed often to stay safe. Companies must inspect forklifts before every shift. They look for problems like worn tires or leaking fluids. They also check for broken lights. Fixing these problems right away stops accidents and keeps work going.

Managing hazards at work is part of standardization too. Employers must keep paths clear and make sure there is enough light. This helps drivers see better and avoid crashes. Safe practices include speed limits and rules for carrying loads. Workers must also talk to each other to stay safe. These steps make every workplace safer.

The table below lists some key forklift standards and their effects:

| Standard/Feature | Description | Impact on Global Manufacturing and Safety |

|---|---|---|

| Operator Training | Mandatory training and certification for all forklift operators, including classroom and hands-on instruction. | Ensures skilled operators, reducing accidents and improving workplace safety globally. |

| Equipment Maintenance | Regular inspections and maintenance to keep forklifts in safe working condition. | Prevents equipment failure, reducing downtime and accidents worldwide. |

| Workplace Hazard Management | Employers must maintain hazard-free environments (clear pathways, adequate lighting). | Creates safer work environments, reducing injury rates in manufacturing. |

| Record Keeping | Documentation of training, inspections, and incidents related to forklift operations. | Enables compliance tracking and continuous safety improvements globally. |

| Safe Operating Practices | Includes age/health requirements, speed limits, load handling, visibility, and communication. | Standardizes safe operation, reducing accidents and improving efficiency. |

| Advanced Safety Technologies | Proximity warning systems, automatic speed control, enhanced visibility aids (cameras, mirrors). | Lowers accident rates, improves productivity, and reduces costs worldwide. |

| Monitoring and Reporting Tools | Real-time tracking (GPS), operational data collection, incident alerts, and data analysis. | Enables proactive safety management and predictive maintenance globally. |

| Legal and Financial Protections | Compliance avoids fines, lawsuits, and operational disruptions. | Encourages global adherence to safety standards, fostering safer industries. |

Standardization also led to a standard forklift pallet size. This made it easier to move goods between countries. Forklifts can now lift and stack pallets the same way everywhere. This change helped global trade and made warehouses more organized.

Note: Standardization did not just make forklifts safer. It also helped companies save money and work faster. Today, these rules guide how every forklift works in factories, warehouses, and shipping centers around the world.

Forklift Uses

People pick forklifts because they move materials faster. Forklifts are also safer than doing the work by hand.

Key Takeaways

Forklifts are strong machines. They lift and move heavy things. People use them in warehouses, factories, and construction sites. Forklifts help move items safely and fast.

Forklifts have two metal forks and a mast. These parts lift pallets straight up. A counterweight helps keep the forklift balanced. This stops it from tipping over.

Electric forklifts are common indoors. They do not make smoke. They are quiet. Their batteries charge quickly and last a long time.

There are many types of forklifts. Each type is made for a special job or place. Some work in narrow aisles. Others work on rough ground or pull heavy loads.

Forklift safety is very important. Operators must get proper training. Equipment needs regular checks. Workers must follow strict rules to avoid accidents.

Forklifts help work go faster. They move materials quickly. This saves money on labor. They also help use storage space better in busy places.

New technology is changing forklifts. Some forklifts can drive themselves. They can track data in real time. New designs make them safer.

People want forklifts to be better for the environment. Electric forklifts help with this. Energy-saving features and recycling are also important. These changes lower costs and help the planet.

Forklift Basics

Warehousing

Forklifts are very important in warehouses. Workers use them to move pallets and boxes. They also move heavy goods from one spot to another. Forklifts help stack things on tall shelves. This lets warehouses use all the space up high. They help organize products for quick picking and packing. In busy places, forklifts load and unload trucks fast. This keeps goods moving and trucks do not have to wait long.

New forklift designs work well in tight aisles. Warehouses can store more items without needing more room. Forklifts keep workers safe by lifting heavy loads. Lifting by hand could hurt someone. Many forklifts have safety features like warning lights and backup alarms. These features help stop accidents and protect people and products.

Tip: Picking the right forklift for each warehouse job helps workers do more and keeps products safe from damage.

Manufacturing

Forklifts do many jobs in factories every day. They move raw materials to the production line. They also carry finished goods to storage or shipping. Forklifts move items between workstations too. This keeps the work moving smoothly.

Factories use forklifts to work faster and better in many ways:

Forklifts move and place goods quickly, so workers do less lifting and there are fewer slowdowns.

They help stack and get items fast, which makes work go better.

Some factories use forklifts with RFID to track inventory in real time. This helps managers make good choices and avoid running out of things.

Forklifts load and unload fast, which helps just-in-time work and stops delays.

Fewer workers are needed because forklifts do more, so labor costs go down and staff can do other jobs.

With forklifts, factories can fill orders fast and keep customers happy. They also make more money. Forklifts help keep workers safe by doing the heavy lifting for them.

Construction

Forklifts do many important jobs on building sites. They move heavy things like bricks, steel beams, and lumber over rough ground. Some forklifts, like telehandlers, lift loads to rooftops or high places. This helps workers get materials where they need them.

The table below shows how forklifts help on construction sites:

| Role/Benefit | Description | Impact on Project Timelines and Construction Sites |

|---|---|---|

| Efficient Material Handling | Forklifts move heavy things fast and safely, even to high spots. | Less manual work and time, so materials are ready and work goes faster. |

| Enhancing Worker Safety | Forklifts lower lifting risks with safety features like load indicators. | Workers stay healthy and focused, so there are fewer delays from injuries. |

| Speeding Up Project Timelines | Moving big loads quickly means work does not stop for manual handling. | Projects finish sooner because materials keep coming. |

| Versatility in Material Placement | Telehandlers put materials in the right spot, so less moving is needed. | Saves time by not having to move things again. |

| Reducing Labor Costs | Forklifts do the heavy lifting, so fewer workers are needed. | Labor costs go down and workers can do other jobs, making work better. |

| Minimizing Material Damage | Forklifts lift things steadily, so materials do not get dropped or broken. | Saves money and keeps projects on track. |

Forklifts help building teams finish jobs faster and safer. They also save money by needing fewer workers and stopping damage to materials. Using the best forklift for each job keeps work going smoothly and on time.

Specialized Industries

Many industries need forklifts to work well. Each industry has its own problems. Forklifts often use special parts or tools. These changes help workers move things safely and quickly.

Forklifts are important in retail stores. Big stores use them to fill shelves and move heavy stuff. Workers can restock fast and keep aisles open. Retail forklifts must handle different products. Some models use attachments for boxes, pallets, or fragile items.

Farmers use forklifts in agriculture. They move equipment and crops. Forklifts carry crates from fields to storage. Some have strong designs for rough ground. Others use tools to lift hay or farm machines. These features save time and reduce hard work.

Warehouses need forklifts to organize goods. Workers use reach trucks in tight spaces. These forklifts are narrow and have tall masts. They help stack items high and pick orders fast. Many warehouses use barcode scanners on forklifts to track goods.

Construction sites use forklifts for heavy materials. They move bricks, steel, and concrete. Rough terrain forklifts work on bumpy ground. These machines have big tires and strong engines. Workers lift loads to high floors or across mud. Building site forklifts have extra safety parts like load indicators and strong cabs.

Factories use forklifts to move materials and products. Workers add clamps, rotators, or drum handlers for different loads. These tools stop damage and keep work moving. Factory forklifts work all day, so they need regular checks.

Some industries use general changes to make forklifts better. Extensions help lift big or odd-shaped things. Sweeper tools keep work areas clean. These changes let one forklift do many jobs and save space and money.

The table below shows how industries use forklifts and what special parts they need:

| Specialized Industry | Forklift Usage Description | Unique Adaptations / Attachments |

|---|---|---|

| Retail | Makes stocking and moving heavy items easy in big stores. | Can change quickly for different products. |

| Agriculture | Moves farm equipment and crops, making farm work faster. | Strong design for heavy machines and crop moving. |

| Warehousing & Storage | Stores, finds, and organizes goods in tight spaces. | Reach trucks made for warehouse use. |

| Construction | Moves bricks, steel, and concrete on building sites. | Rough terrain forklifts for bumpy ground. |

| Manufacturing | Moves materials and products in factories to help work go faster. | Different tools for safe lifting. |

| Building Site Ops | Moves heavy building materials to help building work. | Strong forklifts with more lifting power. |

| General Adaptations | Forklift extensions for big or odd loads and sweepers for cleaning. | Extensions reach farther; sweepers keep areas clean. |

Note: Forklifts help industries work faster and safer. Picking the right forklift and tools makes every job easier.

Forklift Safety

Safety Practices

Forklift safety starts with good habits and clear rules. Many accidents happen because of mistakes that can be stopped. The main causes are not enough training, broken equipment, going too fast, tipping over, and driving with loads up high. Other dangers come from loose loads, turning wrong, and hitting people or other vehicles. Unsafe things like riding on the mast or working in areas without signs also cause injuries.

Tip: Forklift rollovers cause about 24% of accidents and 42% of injuries. Pedestrian collisions make up 20% of accidents and 36% of deaths.

To keep everyone safe, workplaces use strict safety steps:

Operators always wear seatbelts on sit-down forklifts.

No one races or uses forklifts the wrong way.

Drivers honk at blind spots and corners.

Only one person rides unless the forklift is made for more.

Workers block truck wheels before going in with a forklift.

Loads stay down while moving.

Forks go to the ground when parking.

No one lifts people on the forks.

Forklifts get checked before every shift.

No smoking in refueling or charging areas.

These steps help stop accidents and keep everyone safe.

Operator Training

Good training is the key to safe forklift use. Only trained and licensed workers should drive forklifts. Training has classroom lessons and hands-on practice. A trainer teaches the rules and watches each operator work. Employers must certify operators after they pass tests. Certification records have the trainee’s name, training date, and trainer’s name. Operators get checked again every three years or sooner if needed.

| Country | Training Requirements | Certification Process | Refresher Training |

|---|---|---|---|

| United States | Theory and hands-on training (OSHA) | Employer certifies after evaluation | Every 3 years or as needed |

| Canada | Theory and practical (CSA Standard) | Certification after passing tests | Every 3 years |

| United Kingdom | Accredited body certification | Certified through recognized organizations | Periodic refresher required |

| Australia | High Risk Work license | License after approved training | As required by regulations |

| New Zealand | Forklift Operator Certificate | Certification after training and assessment | As required by standards |

| European Union | Varies by country | Accredited training and assessment | Varies by member state |

Well-trained operators know how to move loads, follow traffic rules, and use safety gear. Training lowers injuries, product damage, and equipment downtime. It also helps build a safe and efficient workplace.

Workplace Efficiency

Forklifts help companies work faster and safer. Good safety steps and training make forklifts work better. Operators who follow rules avoid accidents and keep products safe. Workplaces use forklifts to save space, move goods quickly, and cut down handling time. Managers track forklift efficiency with things like task time, error rates, and equipment uptime.

| Forklift Efficiency Contribution | Explanation |

|---|---|

| Space Maximization | Narrow-aisle forklifts fit more items in less space. |

| Handling Volume Optimization | Picking the right forklift means fewer trips. |

| Minimizing Handling Time | Fast, safe moves speed up work. |

| Full-Shift Uptime | Reliable forklifts keep work going all shift. |

| Reducing Product Touch Points | Fewer moves mean less damage and lower costs. |

| Operational Risk Aversion | Backup forklifts help avoid lost time and mistakes. |

When companies focus on safety and efficiency, they have fewer accidents and get more done. Forklifts help keep people safe and help businesses do better.

Future of Forklifts

Automation

Automation is changing how forklifts work in many places. Some companies now use driverless forklifts. These forklifts move things by themselves. They have sensors and cameras to see what is around them. This helps them not bump into things. Warehouses sometimes use groups of robots called AMRs. These robots work together and move goods fast and safely. They can do this even when the warehouse is busy.

Here are some ways automation is used: 1. Automated forklifts use sensors and cameras to drive and lift loads without a person. 2. Warehouses use AMRs that can work together and plan the best routes. 3. Hybrid fleets mix human drivers and robots to get more work done and keep people safe. 4. Data analytics and GPS track forklift performance and help managers make better choices. 5. Augmented reality headsets help train new operators and give real-time instructions.

The market for autonomous forklifts is growing quickly. Experts think it will be worth over $5 billion by 2032. Online shopping and faster delivery needs make companies use more automation.

Sustainability

Sustainability is very important for forklift makers and users. Electric forklifts are taking the place of old gas or diesel ones. These new forklifts use lithium-ion batteries. The batteries last longer and charge faster. They do not make exhaust, so the air stays clean inside.

Key sustainable features include: - Electric forklifts make no emissions and are quieter. - Lithium-ion batteries last longer and charge fast. - Charging with solar or wind power uses less fossil fuel. - Regenerative braking saves energy by reusing power when stopping. - Smart charging systems help use less electricity. - Less maintenance means fewer parts to replace and less waste. - Companies recycle old batteries and fix used forklifts to help the environment.

Electric forklifts use about 20% less energy than diesel ones. They also save money on fuel and repairs over time.

Industry Trends

Many trends are shaping the future of forklifts. More companies pick electric forklifts for cleaner and quieter work. Smart forklifts use IoT to send real-time data about where they are and how they work. This helps managers fix problems before they slow down work.

Other important trends include: - Automation with self-driving forklifts and smart routing. - Ergonomic designs make driving safer and more comfortable. - Safety improvements like sensors, cameras, and virtual reality training. - Data analytics to track performance and plan maintenance. - Eco-friendly manufacturing and recycling programs.

The table below shows some of the biggest trends:

| Trend | Description |

|---|---|

| Electrification | More electric forklifts for cleaner, quieter operation |

| Smart Technology | IoT and sensors for real-time monitoring |

| Automation | Driverless forklifts and robots in warehouses |

| Ergonomics | Better seats and controls for operator comfort |

| Safety Enhancements | Sensors, cameras, and VR training for fewer accidents |

| Sustainability | Zero emissions and recycling efforts |

Note: These trends help companies work faster, safer, and with less harm to the environment.

Forklifts are still very important in today’s industry. They began as basic lifting tools but now help move goods all over the world.

Forklifts use electric power, automation, and smart sensors to make work safer and faster.

Companies need forklifts to load things quickly, stack items high, and keep track of inventory.

Using used and fixed-up forklifts saves money and helps the environment.

As technology gets better, forklifts will keep changing to solve new problems in moving and making things.

FAQ

What is the main job of a forklift?

A forklift picks up and moves heavy things. Workers use it to stack, store, and carry stuff. Forklifts help in warehouses, factories, and building sites.

How much weight can a forklift lift?

Most forklifts lift 3,000 to 5,000 pounds. Some big models lift up to 100,000 pounds. The weight limit depends on the forklift type.

Who can operate a forklift?

Only trained and certified people drive forklifts. Workers must finish safety lessons and pass a test first.

Why do forklifts have a counterweight?

A counterweight helps keep the forklift steady. It stops the forklift from tipping when lifting heavy things. The counterweight is at the back.

What types of fuel do forklifts use?

Forklifts use electricity, propane, gasoline, or diesel. Electric forklifts are best for inside work. Gasoline and diesel forklifts work well outside.

How do workers stay safe around forklifts?

Workers follow safety rules and wear seatbelts. They check the forklift before using it. Loads stay low when moving. No one rides on the forks. Training helps stop accidents.

What is the difference between a forklift and a pallet jack?

A forklift lifts things higher and moves heavier stuff. A pallet jack moves pallets a short way on the ground. Forklifts need trained drivers, but pallet jacks do not.

Can forklifts work outdoors?

Yes, many forklifts work outside. Pneumatic tires help on rough ground. Diesel and propane forklifts are good for outdoor jobs. Electric forklifts are better for inside.

English

English